Aluminum Coil Ontario - Wooden Coated Good Quality 1060 3003 3105

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

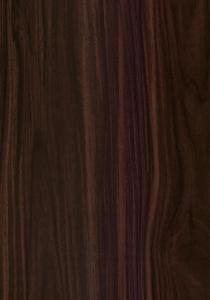

Structure of Aluminum Coil Wooden Coated Good quality 1060 3003 3105 Description:

Aluminum Coil Wooden Coated Good quality 1060 3003 3105are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.The Aluminum Coil Wooden Coated Good quality 1060 3003 3105 have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminum Coil Wooden Coated Good quality 1060 3003 3105:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminum Coil Wooden Coated Good quality 1060 3003 3105:

Aluminum Coil Wooden Coated Good quality 1060 3003 3105 Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Is it possible to recycle aluminum coils in various countries around the world?

- <p>Yes, aluminum coils can be recycled in many countries around the world. Recycling aluminum is a global practice due to its high value and the energy savings associated with recycling compared to producing aluminum from raw materials. Different countries have their own recycling programs and facilities that handle aluminum waste, including coils. However, the specific regulations and processes for recycling aluminum coils can vary by country, and it's important to check local recycling guidelines to ensure proper disposal and recycling.</p>

- Q: Is it safe to use aluminum foil to wrap food for cooking purposes?

- <p>Yes, you can use aluminum foil to wrap food for cooking. Aluminum foil is commonly used for wrapping, baking, and cooking food in the oven, grill, or on the stovetop. It helps retain moisture, prevents food from sticking, and can be used to create a sealed environment for steaming or baking. However, it's important to avoid using aluminum foil at very high temperatures as it can react with acidic or alkaline foods and potentially leach aluminum into the food. Always follow the manufacturer's guidelines for safe use and cooking temperatures.</p>

- Q: im looking for a bat but i dont know what to get wood or aluminum what is harder wood or aluminum ?? what would be better for hitting hard balls with ( or maybe people ) haha no im joking i need help !!!!

- aluminum is, and hardness isnt everything.. theres bat speed, vibration differences after the swing, wider sweet spots, and durability. aluminum bats dominate wood bats in all these catergories

- Q: Using principles of chemical bonding, explain why solid aluminum is a good conductor of electricity but solid aluminum chloride is not. NaCl has a boiling point of 1413 degrees celcius wheras BrCl has a boiling point of 5 degrees celcius. Account for this difference using chemical bonding and molecular structure.

- Pure aluminium is a good conductor because it's atoms are metalically bonded. This means it's electrons are delocalised and can therefore produce a current. NaCl has a high boiling point because in order to evaporate it first needs to melt. And to melt it you need to break it's lattice structure. Na and Cl atoms are held by strong ionic bonds. BrCl on the other hand is covalently bonded. It's molecular structure does not need to be broken in order for it to melt or boil. All that has to be done is weak van der waal bonds need to be broken.

- Q: Are aluminum coils suitable for heat exchangers?

- Aluminum coils are indeed a fitting choice for heat exchangers. This is because aluminum possesses exceptional thermal conductivity, making it highly efficient and effective in transferring heat between mediums. Its ability to swiftly transfer heat from one medium to another is particularly advantageous for heat exchangers that require efficient heat transfer. Furthermore, aluminum coils are lightweight, resistant to corrosion, and boast excellent durability. These qualities contribute to their popularity in a wide range of applications, including heat exchangers. The corrosion resistance of aluminum ensures that the coils can endure harsh environments and prevent the occurrence of rust or corrosion, thereby prolonging the heat exchanger's lifespan. Moreover, aluminum coils are easily moldable and can be shaped into various forms, allowing for flexibility in designing and constructing heat exchangers. This adaptability makes them suitable for a diverse array of applications, such as HVAC systems, refrigeration units, and automotive cooling systems. In conclusion, the high thermal conductivity, lightweight nature, corrosion resistance, durability, and versatility of aluminum coils make them well-suited for heat exchangers. These properties establish aluminum coils as an excellent choice for achieving efficient heat transfer in numerous industries.

- Q: What is the typical thermal expansion coefficient for aluminum coils?

- The aluminum coils usually have a thermal expansion coefficient of approximately 23.1 x 10^-6 per degree Celsius (or 23.1 x 10^-6/°C). This coefficient signifies the alteration in length of an aluminum coil with each degree Celsius rise in temperature. It is worth mentioning that this figure might slightly differ based on the particular alloy and composition of the aluminum coil.

- Q: How are aluminum coils used in insulation applications?

- Aluminum coils are commonly used in insulation applications as they are lightweight, durable, and have excellent thermal conductivity properties. They are typically used to create a radiant barrier or reflective insulation, where they are installed between the outer walls or roofs of a building and the insulation material. The reflective surface of the aluminum coil helps to reflect radiant heat away from the building, reducing heat transfer and improving energy efficiency. Additionally, aluminum coils are also used in HVAC systems to create air ducts that ensure proper insulation and prevent heat loss or gain.

- Q: What are the potential applications of recycled aluminum coils?

- Due to their numerous advantageous properties, recycled aluminum coils offer a wide range of potential applications. One such application lies in the manufacturing of automotive parts, where aluminum coils can be utilized to create lightweight body panels, engine components, and structural parts. This, in turn, can effectively decrease the overall weight of vehicles, leading to enhanced fuel efficiency and reduced emissions. In the construction industry, recycled aluminum coils can be employed to produce roofing materials, siding, gutters, and window frames. Aluminum's durability, corrosion resistance, and ability to withstand extreme weather conditions make it an ideal choice for construction purposes. Moreover, packaging materials can benefit from the use of recycled aluminum coils. Aluminum's exceptional barrier properties make it a popular choice for manufacturing beverage cans, food containers, and foil packaging. This aids in preserving the freshness and quality of the packaged products, while also reducing the environmental impact associated with the production of new aluminum and minimizing waste. Furthermore, the production of electrical equipment can make use of recycled aluminum coils. Aluminum's excellent conductivity of electricity makes it suitable for manufacturing electrical wires, cables, and other components. This not only conserves energy but also reduces the necessity for extracting and processing virgin aluminum. In conclusion, the potential applications of recycled aluminum coils span across various sectors, including automotive, construction, packaging, and electrical equipment. By embracing the utilization of recycled aluminum coils, we can achieve both environmental and economic benefits by reducing waste, conserving resources, and promoting sustainability.

- Q: Today at my school I was messing with this sketch thingy, the one with 2 knobs to twist up or down to draw, my friend decided to break it and when we broke it, this silver dust called aluminum powder got on my hands, I never knew it was dangerous cause your see, we never read the manual we just found it. About 3 minutes later he pointed to my hand and I saw blood. It kinda stung.

- The aluminum powder found in an Etch-a-Sketch will not cut you, it's much too small. In fact it's so small you could only see it's edges under a high powered microscope. The cut was most likely caused by jagged glass/plastic when you broke the Etch-a-Sketch open. It's not unusual to cut yourself and not realize until someone else sees you're bleeding.

- Q: This question asks for a comparison of the benefits and drawbacks associated with the use of aluminum coil in various applications.

- <p>The advantages of using aluminum coil include its lightweight nature, which reduces transportation costs and enhances energy efficiency. It also has excellent thermal conductivity, making it ideal for heat exchangers and cooking utensils. Aluminum coil is corrosion-resistant, which extends its lifespan and reduces maintenance. It is also recyclable, contributing to sustainability. Disadvantages include lower strength compared to steel, which may limit its use in heavy-duty applications. It also has a higher cost than some other metals, which can affect its competitiveness in certain markets. Additionally, aluminum is a good conductor of electricity, which can be a disadvantage in applications where electrical insulation is required.</p>

Send your message to us

Aluminum Coil Ontario - Wooden Coated Good Quality 1060 3003 3105

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords