PVDF Coated Aluminum Coil China - Color Coated Aluminum Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Profile with PVDF Coated and Color Coated Description:

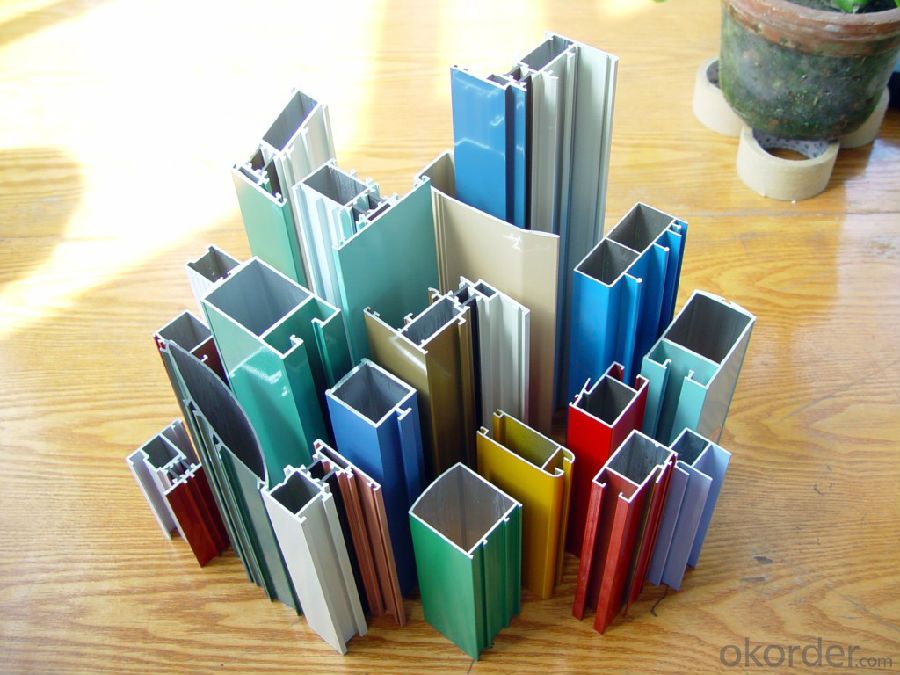

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Profile with PVDF Coated and Color Coated:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

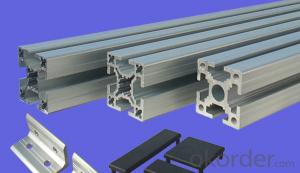

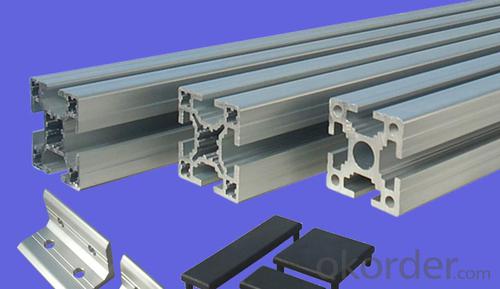

Images of the Aluminium Profile with PVDF Coated and Color Coated:

Aluminium Profile with PVDF Coated and Color Coated Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Are aluminum coils resistant to abrasion?

- Aluminum coils are typically resistant to abrasion, thanks to their durability and ability to withstand wear and tear. Known for its high strength-to-weight ratio and exceptional corrosion resistance properties, aluminum is well-suited for applications that demand abrasion resistance. Moreover, protective finishes are commonly applied to aluminum coils, further bolstering their ability to resist abrasion. Nevertheless, the exact level of resistance can vary depending on the particular alloy and surface treatment used on the coils.

- Q: This question asks for methods to assess the quality of aluminum coil, which is important in industries where aluminum products are used.

- <p>To check the quality of aluminum coil, you should inspect its surface for any defects like scratches, dents, or discoloration. Measure its thickness and width to ensure they meet the specified standards. Test its mechanical properties, such as tensile strength and elongation, to verify its strength and flexibility. Conduct a chemical analysis to confirm the alloy composition and purity. Check for any impurities or inclusions that could affect performance. Finally, assess the coil's flatness and straightness to ensure it's suitable for further processing.</p>

- Q: What certifications might be necessary for the production, sale, or use of aluminum coils?

- <p>Aluminum coils may require various certifications depending on their intended use and the standards set by different countries or industries. Common certifications include ISO 9001 for quality management systems, ISO 14001 for environmental management, and specific industry standards such as ASTM or EN standards for material properties and safety. For construction or automotive applications, additional certifications like CE marking in Europe or DOT certification in the US may be necessary. It's crucial to consult with industry standards and regulatory bodies to determine the exact certifications required for a specific application.</p>

- Q: How are aluminum coils tested for flatness?

- Various methods are employed to test the flatness of aluminum coils, guaranteeing their compliance with the necessary standards. One commonly used approach involves the utilization of a straight edge. In this method, a lengthy and meticulously precise straight edge is placed on the coil's surface. Technicians then visually inspect for any discrepancies or gaps between the straight edge and the coil. The presence of such gaps indicates that the coil is not flat, necessitating further examination. Another technique utilized is the straight edge ruler method. Here, a ruler with a thin and flexible edge is applied to the surface of the coil. By applying gentle pressure, technicians can identify any areas where the ruler fails to fully make contact with the coil, indicating irregularities in its flatness. Advanced methods, including laser or optical techniques, are also employed to assess the flatness of aluminum coils. These methods employ laser beams or optical sensors to measure the surface profile of the coil. The collected data is then analyzed to determine if there are any deviations from the desired flatness. These sophisticated techniques provide precise and accurate results, enabling a more comprehensive evaluation of the coil's flatness. In conclusion, the testing of aluminum coils for flatness is of utmost importance in ensuring that they meet the required standards for a variety of applications. By utilizing a combination of visual inspection, straight edge techniques, and advanced laser or optical methods, manufacturers can guarantee that the coils are flat and devoid of any irregularities that could impact their performance.

- Q: Can aluminum coils be used in the production of chemical storage tanks?

- Yes, aluminum coils can be used in the production of chemical storage tanks. Aluminum is a durable and corrosion-resistant material, making it suitable for containing various chemicals. Additionally, its lightweight nature allows for easier handling and installation of the storage tanks.

- Q: How are aluminum coils inspected for quality?

- Aluminum coils are inspected for quality through a series of rigorous tests and inspections. These inspections are crucial to ensure that the coils meet the required industry standards and specifications. One common method used to inspect aluminum coils is visual inspection. Trained inspectors visually examine the coils for any visible defects such as surface scratches, dents, or any other physical imperfections that may affect the quality of the coil. This inspection is typically done using specialized lighting and magnification equipment to ensure thorough examination. Another important inspection method is dimensional inspection. In this process, the dimensions of the aluminum coils are measured and compared against the specified tolerances. This helps ensure that the coils meet the required size and shape requirements. Coating inspection is also an essential part of the quality inspection process. The coating on aluminum coils is inspected for uniformity, adhesion, and thickness. Specialized instruments are used to measure the coating thickness and ensure that it meets the specified requirements. Additionally, mechanical properties such as tensile strength, yield strength, and elongation are tested to assess the strength and durability of the aluminum coils. These tests involve subjecting samples from the coils to controlled stress and measuring their response. Lastly, various non-destructive testing techniques are employed to detect any hidden defects or flaws that may not be visible to the naked eye. These techniques include ultrasonic testing, eddy current testing, and dye penetrant testing. These methods help identify any internal defects such as cracks or voids that could compromise the quality of the aluminum coils. Overall, a combination of visual inspections, dimensional measurements, coating inspections, mechanical property testing, and non-destructive testing techniques are employed to thoroughly inspect aluminum coils and ensure their quality before they are deemed suitable for use in various industries such as construction, automotive, and aerospace.

- Q: Can aluminum coils be used in high-vibration environments?

- Indeed, high-vibration environments can accommodate the utilization of aluminum coils. Renowned for its remarkable strength-to-weight ratio, aluminum possesses the capacity to endure vibrations without undergoing substantial deformation or fracture. Moreover, its outstanding corrosion resistance characteristics render it suitable for diverse environmental circumstances. Consequently, it is frequently employed in sectors like automotive, aerospace, and electronics, where high-vibration environments prevail. Nevertheless, it is imperative to guarantee the appropriate design and installation of aluminum coils to mitigate any potential complications arising from vibration.

- Q: What are the precautions to be taken while handling aluminum coils?

- Some precautions to be taken while handling aluminum coils include wearing protective gloves to prevent cuts or injuries, using proper lifting techniques to avoid strain or back injuries, storing coils in a dry and well-ventilated area to prevent corrosion, using appropriate equipment and tools for handling and transportation, and following safety guidelines provided by the manufacturer. It is also important to be aware of the weight and balance of the coils to prevent accidents or damage.

- Q: Can aluminum coils be used in the production of beverage cans?

- Yes, aluminum coils can be used in the production of beverage cans. Aluminum is a preferred material for the manufacturing of beverage cans due to its lightweight, durability, and ability to preserve the taste and quality of the contents. Coils made of aluminum are typically used in the canning process as they can be easily shaped into a can form. The coils are rolled into sheets, which are then cut and formed into cans. Aluminum coils also have excellent heat conductivity, allowing for efficient cooling and faster production speeds. Overall, aluminum coils are an essential component in the production of beverage cans and are widely used in the industry.

- Q: Are aluminum coils fire-resistant?

- Aluminum coils possess fire-resistant qualities due to their high melting point of 660 degrees Celsius (1220 degrees Fahrenheit) and their inability to burn, rendering them non-combustible. This specific characteristic allows for the utilization of aluminum coils in various applications, particularly in sectors where fire resistance is of utmost importance, such as building construction, electrical wiring, and HVAC systems. Moreover, the remarkable heat conductivity of aluminum facilitates rapid heat dissipation, thereby minimizing the risk of fire incidents. Nevertheless, it is crucial to acknowledge that although aluminum coils themselves exhibit fire-resistant properties, they may be incorporated into systems alongside other components that might not share the same level of fire resistance. Consequently, it is essential to consider the entirety of the system and adhere to proper fire safety regulations and guidelines to ensure comprehensive fire safety precautions.

Send your message to us

PVDF Coated Aluminum Coil China - Color Coated Aluminum Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords