Aluminum Mill Coil PVDF Coated Mill Finished Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Mill Finished PVDF Coated Aluminium Composite Panel Description

Mill Finished PVDF Coated Aluminium Composite Panel is one semi-finished aluminium material. It can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished PVDF Coated Aluminium Composite Panel

Mill Finished PVDF Coated Aluminium Composite Panel | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished PVDF Coated Aluminium Composite Panel

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished PVDF Coated Aluminium Composite Panel

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished PVDF Coated Aluminium Composite Panel

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

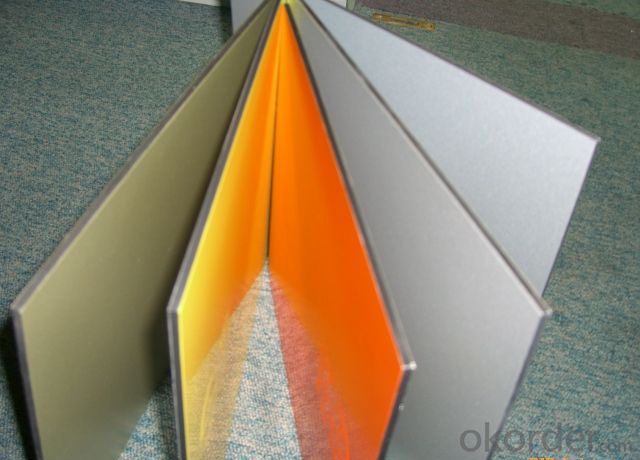

6. Image of Mill Finished PVDF Coated Aluminium Composite Panel

7. Package and shipping of Mill Finished PVDF Coated Aluminium Composite Panel

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum coils suitable for coil slitting applications?

- Yes, aluminum coils are suitable for coil slitting applications. Aluminum is a versatile and lightweight material that can be easily processed and slit into various widths, making it ideal for industries like automotive, construction, and packaging. Its high strength-to-weight ratio and corrosion resistance make aluminum coils a reliable choice for coil slitting applications.

- Q: This question asks for methods to determine whether an aluminum coil is new or old.

- <p>To determine if an aluminum coil is new or old, you can look for several signs: 1. Surface appearance: New coils typically have a clean, smooth surface without scratches or discoloration. 2. Packaging: New coils are usually well-packaged and protected. 3. Manufacturing date: Check for any labels or markings that indicate the manufacturing date. 4. Quality of the material: New coils should have consistent thickness and no signs of corrosion or wear. 5. Performance: New coils should perform as expected without any issues. If you're still unsure, consider consulting with a professional or the supplier for more information.</p>

- Q: Can aluminum coils be used in low-friction applications?

- Yes, aluminum coils can be used in low-friction applications. Aluminum's low coefficient of friction and excellent thermal conductivity make it a suitable material for various applications where low friction is desired, such as in sliding mechanisms, bearings, and electrical connectors.

- Q: Explain how aluminum coils impact transportation, including considerations for logistics and safety.

- <p>Aluminum coils significantly affect transportation due to their weight and size. They are heavy and bulky, which requires specialized vehicles for transportation to ensure stability and prevent damage. The weight of aluminum coils can impact fuel efficiency and may require more powerful vehicles, increasing fuel consumption and emissions. Additionally, the transportation of aluminum coils must adhere to strict safety regulations to prevent accidents, especially when transported over long distances or on public roads. This can involve securing the load properly, using appropriate transport methods, and ensuring drivers are trained to handle heavy loads. The logistics of transporting aluminum coils can be complex, requiring careful planning and coordination to minimize delays and costs.</p>

- Q: What are the potential applications of coil-laminated aluminum coils?

- Coil-laminated aluminum coils have a wide range of potential applications in various industries. They can be used in the manufacturing of automotive parts, such as body panels and interior components, due to their lightweight yet durable nature. Additionally, they are suitable for building and construction purposes, including roofing, siding, and insulation, as they offer excellent corrosion resistance and thermal conductivity. Furthermore, coil-laminated aluminum coils find use in electrical industries for producing transformers, capacitors, and other electrical components due to their excellent electrical conductivity. Overall, their versatility and desirable properties make coil-laminated aluminum coils valuable in numerous applications across different sectors.

- Q: I need to lay down two 3 welds on some 1/8 aluminum but my welder is not set up for it. could i just out fit my welder with aluminum wire without buying the spool gun and get the same results? or maybe I should just get a welding shop to do it for me?

- Hi. You need a spherical tip on, say, a mig welder to be successful when welding aluminum. Spreads out the heat better.

- Q: What is the structure of Aluminium Chloride at 180, 192.4 (melting point) and 200 degrees celsius? When does it exist as an ionic lattice and when as a Al2Cl6 dimer?

- Aluminium chloride sublimes (turns straight from a solid to a gas) at about 180°C. If it simply contained ions it would have a very high melting and boiling point because of the strong attractions between the positive and negative ions. The implication is that it when it sublimes at this relatively low temperature, it must be covalent. The dots-and-crosses diagram shows only the outer electrons. Hope that help Check here for more information; www.chemguide .uk/atoms/bonding...

- Q: Are aluminum coils suitable for heat exchanger applications?

- Yes, aluminum coils are suitable for heat exchanger applications. Aluminum has excellent thermal conductivity and corrosion resistance properties, making it an ideal choice for heat transfer in various industries such as HVAC, automotive, and refrigeration. Additionally, aluminum coils are lightweight and cost-effective, making them a popular option for heat exchangers.

- Q: Can aluminum coils be used in roofing or cladding systems?

- Yes, aluminum coils can be used in roofing or cladding systems. Aluminum is a lightweight and corrosion-resistant material, making it suitable for these applications. It offers durability, flexibility, and ease of installation, making it a popular choice in the construction industry.

- Q: Are there any fire safety considerations when using aluminum coils?

- Yes, there are fire safety considerations when using aluminum coils. Aluminum is a highly flammable material, and if not handled and installed properly, it can pose a fire risk. It is important to ensure that the aluminum coils are installed in a way that minimizes the risk of fire, such as using proper insulation and avoiding direct contact with other flammable materials. Additionally, regular maintenance and inspections should be conducted to identify any potential issues or signs of overheating that could lead to a fire. Following fire safety protocols and guidelines, such as having a fire extinguisher nearby and ensuring proper ventilation, can also help mitigate the fire risk associated with using aluminum coils.

Send your message to us

Aluminum Mill Coil PVDF Coated Mill Finished Aluminium Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords