6061 Aluminum Coil - Roll of Aluminum 3003 H14 /1100 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

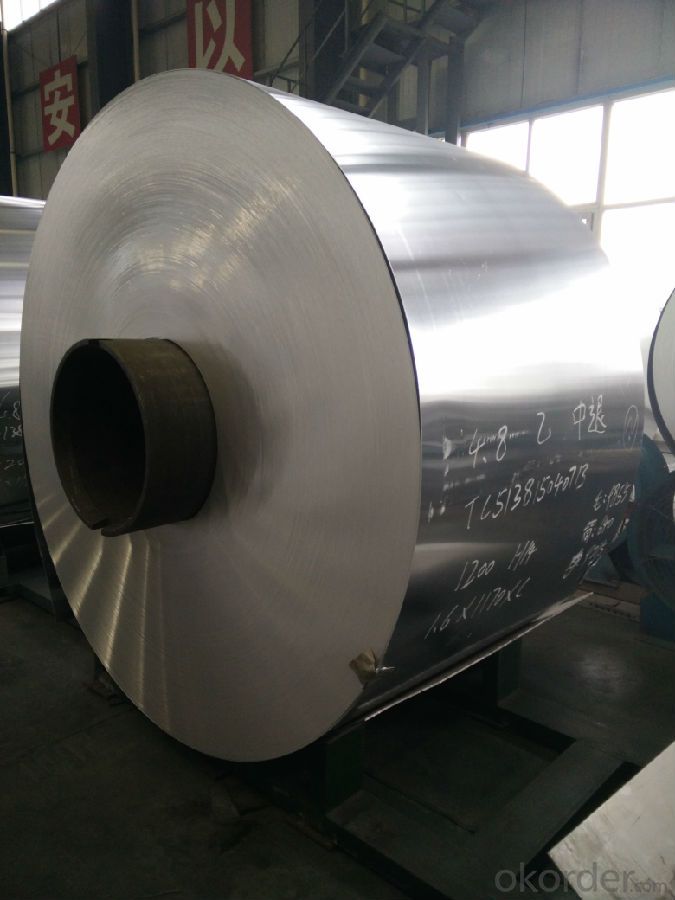

1.Structure of Roll of Aluminum 3003 H14 /1100 H14

Roll of Aluminum 3003 H14 /1100 H14 is designed for many field such as electronics, instruments, lighting decoration, packing industry, and house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel, aluminum composite pipe etc.. Roll of Aluminum 3003 H14 /1100 H14 is hard and everlasting under the blazing sun. You can choose the alloys as your habitation and we will do our best to meet your requests.

2.Main Features of the Roll of Aluminum 3003 H14 /1100 H14:

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

3. Roll of Aluminum 3003 H14 /1100 H14

Alloy: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-100mm

Width: 30mm-1700mm

4. Production of Roll of Aluminum 3003 H14 /1100 H14

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: hello I'm building a TIG welder and have found the output from my stick welders to be not so good for aluminum(60 Hz on one). I've heard that high frequency AC is the way to do AL but am not sure what constitutes high. I do have a nice miller gas driven welder also that is maybe triple the frequency of my line driven one but still had issues with it. does anyone know of an actual # ? I may be able to build an inverting PWM supply eventually to do this but am not sure what I would need it to do. does anyone have any data that might help? any data/tips about aluminum would be appreciated, thanks in advance. FYI I do understand why AC works so much better on AL, what with the oxides that are always present.

- NO... the TIG rods are uncoated and will not be able to create the shielding gas like coated rods would when used in an ARC welder. TIG (Tungsten Inert Gas) uses a shielding gas supplied from a tank, the aluminum rods are used as filler material and metled into the weld by the operator by using the arc from the tip as the heat source. Two different welding processes, hence the need for two different types of rods...

- Q: Is it possible to use an aluminum coil as a paperweight for holding down papers?

- <p>Yes, you can use an aluminum coil as a paperweight. Aluminum is a lightweight and sturdy metal that can effectively hold down papers on a desk. Its weight and shape make it suitable for this purpose. However, ensure the coil is clean and smooth to avoid any damage to the papers or surfaces it comes into contact with. Additionally, consider the size and thickness of the coil to ensure it provides enough weight to keep your papers in place.</p>

- Q: How do aluminum coils compare to other metals in terms of strength?

- Aluminum coils generally have lower strength compared to other metals such as steel or titanium. While aluminum is lightweight and offers good corrosion resistance, it may not possess the same level of strength and durability as some other metals. However, the specific strength of aluminum coils can vary depending on the alloy composition and manufacturing process.

- Q: How do aluminum coils contribute to fire safety?

- Aluminum coils contribute to fire safety by being non-combustible and having a high melting point. This means that in the event of a fire, aluminum coils will not burn or contribute to the spread of flames. Additionally, they are often used in fire-resistant building materials and electrical wiring due to their ability to dissipate heat efficiently, reducing the risk of fire hazards.

- Q: How are aluminum coils used in the production of HVAC components?

- The production of HVAC components relies heavily on the use of aluminum coils, which play a crucial role in the process. These coils are utilized in HVAC systems to facilitate heat transfer, contributing to both heating and cooling applications. In air conditioning units and heat pumps, aluminum coils are commonly employed within HVAC systems. They form an integral part of the refrigeration cycle, enabling the transfer of heat from one area to another. Acting as the key component in the heat exchanger, the coils are responsible for absorbing heat from indoor air during the cooling process, or releasing heat into indoor air during heating. The process commences with the circulation of refrigerant, a substance that passes through the coils, absorbing and releasing heat. When the HVAC system is in cooling mode, the aluminum coils function as an evaporator. Warm air from the indoor space passes over the coils, and the refrigerant within absorbs the heat, effectively cooling down the air. This cooled air is then circulated back into the room, providing a comfortable environment. Conversely, during heating mode, the aluminum coils operate as a condenser. The refrigerant, having absorbed heat from the external environment, flows through the coils. The cooler air from the indoor space moves over the coils, causing the refrigerant to release its heat. This heat is then distributed throughout the room, ensuring a warm and cozy atmosphere. The utilization of aluminum coils in HVAC systems offers numerous advantages. Aluminum is lightweight, enhancing the portability and ease of installation of HVAC units. Additionally, aluminum possesses excellent thermal conductivity, enabling efficient heat transfer. As a result, energy efficiency is improved, leading to reduced operating costs of the HVAC system. Furthermore, aluminum coils exhibit high resistance to corrosion, ensuring their durability and longevity. They can withstand harsh environmental conditions, including humidity and exposure to chemicals, without deteriorating. This makes aluminum coils a reliable and cost-effective choice for HVAC manufacturers. In conclusion, aluminum coils play an indispensable role in the production of HVAC systems, facilitating efficient cooling and heating functions through the process of heat transfer. Their lightweight nature, excellent thermal conductivity, and resistance to corrosion contribute to the overall performance, energy efficiency, and durability of HVAC units.

- Q: What are the various dimensions and specifications of aluminum coils available in the market?

- <p>Aluminum coils come in various sizes and specifications to cater to different industrial needs. Common sizes include thicknesses ranging from 0.005 to 0.5 inches (0.13 to 12.7 mm), widths from 1 to 72 inches (25 to 1829 mm), and lengths from 10 to 6000 feet (3 to 1829 meters). The specific dimensions can vary based on the manufacturer and the application, such as construction, automotive, or packaging. It's important to consult with suppliers for the exact sizes available for a particular project or application.</p>

- Q: Are aluminum coils suitable for high-temperature applications?

- High-temperature applications are generally not suitable for aluminum coils due to their low melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit). Aluminum, despite its advantageous properties like lightweight and corrosion resistance, cannot withstand the extreme heat associated with such environments. In contrast, materials with higher melting points like stainless steel or nickel alloys are often preferred for high-temperature settings. These materials can endure higher temperatures without compromising their structural integrity or experiencing significant deformation. However, it is important to note that certain aluminum alloys have been developed to possess improved high-temperature properties. These alloys incorporate elements like copper, magnesium, or zinc, which enhance their strength and heat resistance. As a result, these specialized aluminum alloys may be suitable for specific high-temperature applications that require their unique properties. To summarize, standard aluminum coils may not be appropriate for high-temperature applications, but specialized aluminum alloys are available to offer better performance in elevated temperature environments. It is crucial to consider the specific temperature requirements and consult experts to determine the most suitable material for a particular high-temperature application.

- Q: Can aluminum coils be formed into different shapes?

- Yes, aluminum coils can be formed into different shapes. Aluminum is a highly malleable metal, which means it can easily be bent, shaped, and formed without breaking. This property makes it an ideal material for various applications where flexibility and versatility are required. Aluminum coils can be formed into different shapes using a variety of techniques, such as bending, rolling, stamping, extrusion, or even by using specialized machinery like a coil forming machine. These processes allow the aluminum coils to be transformed into a wide range of shapes, including sheets, plates, tubes, wires, or complex three-dimensional forms. The ability to form aluminum coils into different shapes makes it an excellent choice for industries such as construction, automotive, aerospace, and manufacturing, where customized parts and components are often needed.

- Q: Can aluminum foil coil be stores for a long time?

- It is ok within one or two years, but for five or six years, it will be oxidized.

- Q: How are aluminum coils used in the manufacturing of signage?

- Aluminum coils are widely used in the manufacturing of signage due to their numerous beneficial properties. These coils are typically made from high-quality aluminum alloy, which offers excellent corrosion resistance and durability, making them ideal for outdoor applications. The first step in using aluminum coils for signage manufacturing is the process of coil slitting. This involves cutting the large aluminum coils into smaller, more manageable sizes that can be easily shaped and formed to meet specific design requirements. This slitting process ensures that the coils are the right width and thickness for the desired signage application. Once the coils are properly sized, they are typically fed into a roll-forming machine. This machine allows for the precise shaping of the aluminum coils into the desired signage profiles, such as flat panels, letters, or channel letters. The flexibility of aluminum allows for intricate and customized designs to be easily achieved. Aluminum offers great versatility in terms of finishing options. The coils can be coated with various protective finishes, such as polyester or PVDF coatings, which provide enhanced durability and resistance to fading, chipping, or peeling. These finishes also allow for a wide range of color choices, enabling signage manufacturers to create eye-catching and vibrant displays. Furthermore, aluminum coils are lightweight, making them easier to handle during the fabrication process and reducing transportation costs. Their lightweight nature also makes them suitable for mounting on various surfaces, such as walls, poles, or freestanding structures. In summary, aluminum coils play a crucial role in the manufacturing of signage by providing a durable, corrosion-resistant, lightweight, and versatile material. They can be easily shaped and formed to create customized designs, and their protective finishes ensure long-lasting and visually appealing signage displays.

Send your message to us

6061 Aluminum Coil - Roll of Aluminum 3003 H14 /1100 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords