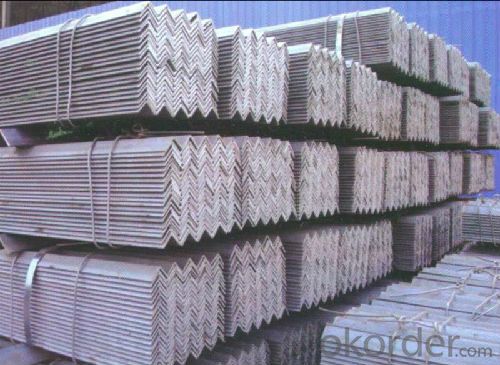

HOT ROLLED STEEL EQUAL ANGLE for construction JIS G3192

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering hot rolled steel equal angle for construction JIS G3192at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot rolled steel equal angle are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's steel equal angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricin

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

:

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

FAQ:

Q1: How do we guarantee the quality of our products?A1: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q2: How soon can we receive the product after purchase

A2: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: What are the common uses of unequal steel angles?

- Unequal steel angles are commonly used in construction, engineering, and fabrication projects. They are often used as structural supports, providing stability and strength in frameworks, buildings, and bridges. These angles are also used for creating bracing systems, reinforcing corner joints, and as components in machinery and equipment. Additionally, they are utilized in architectural designs for decorative purposes, adding aesthetic appeal to structures.

- Q: What does "L125*8" stand for in steel structures?

- Equal angle steel, width 125, wall thickness 8

- Q: What is the meaning of the number of angle steel

- The model does not mean the size of the different edges and sizes of the same model. Therefore, the width, the edge and the thickness of the angle iron should be filled out in the contract and other documents, so as not to be indicated by the model alone. The specification for hot rolled equilateral angle iron is No. 2 - 20.

- Q: Are steel angles suitable for bridge construction?

- Yes, steel angles are suitable for bridge construction. They are commonly used as structural elements in bridge construction due to their strength, durability, and versatility. Steel angles offer excellent load-bearing capacity and can be easily fabricated and connected to form various bridge components such as trusses, beams, and girders. Their ability to withstand heavy loads and resist deformation makes them an ideal choice for bridge construction projects.

- Q: Can steel angles be used in automotive chassis construction?

- Yes, steel angles can be used in automotive chassis construction. Steel angles, also known as angle irons, are commonly used in the construction industry for their strength and versatility. In automotive chassis construction, steel angles can be used to provide structural support and reinforcement to the chassis frame. Steel angles are often used to create the frame structure of a vehicle's chassis, providing a stable and rigid framework. They can be used to form the main longitudinal and cross members, as well as other structural components. The use of steel angles in automotive chassis construction offers several advantages. Firstly, steel is a strong and durable material, making it suitable for withstanding the various stresses and loads experienced by the chassis. Steel angles can also be easily fabricated and welded, allowing for flexibility in design and customization. Moreover, steel angles are cost-effective compared to other materials such as aluminum or carbon fiber. This makes them a popular choice in automotive chassis construction, especially for mass-produced vehicles where cost efficiency is crucial. However, it is important to consider the specific requirements and regulations of the automotive industry when using steel angles in chassis construction. Chassis design must meet certain safety standards, including crashworthiness and structural integrity. Therefore, it is essential to ensure that the chosen steel angles and their dimensions are appropriate for the intended application and comply with relevant regulations. In conclusion, steel angles can indeed be used in automotive chassis construction. Their strength, versatility, cost-effectiveness, and ease of fabrication make them a suitable choice for creating the frame structure of a vehicle's chassis. However, it is important to consider safety regulations and ensure that the chosen steel angles meet the required standards.

- Q: Can steel angles be bolted together?

- Yes, steel angles can be bolted together. Bolting steel angles is a common method of joining them to create various structures or frameworks.

- Q: Can steel angles be used for machinery frames?

- Certainly, machinery frames can utilize steel angles. The construction and manufacturing industries frequently employ steel angles due to their robustness and adaptability. They serve as a means of furnishing structural reinforcement and stability in a multitude of applications, including machinery frames. Steel angles present an economically viable option as they are readily accessible and can be conveniently crafted to meet precise design specifications. Moreover, steel angles exhibit exceptional load-bearing capability and resistance to deformation, rendering them well-suited for supporting hefty machinery and equipment. Their inflexible and long-lasting characteristics guarantee the steadfastness and endurance of machinery frames, establishing them as a dependable choice within industrial environments.

- Q: Which is cheaper, angle iron or steel pipe?

- Angle iron and steel pipe, angle iron is cheap.

- Q: What are the advantages of using steel angles in construction?

- There are several advantages of using steel angles in construction: 1. Strength and durability: Steel angles are known for their high tensile strength, making them an ideal choice for construction projects that require structural support. They can withstand heavy loads and provide stability, ensuring the longevity and safety of the structure. 2. Versatility: Steel angles come in various sizes and dimensions, allowing for flexibility in design and construction. They can be easily cut, welded, and shaped to fit specific requirements, making them suitable for a wide range of applications. 3. Cost-effective: Steel angles are relatively inexpensive compared to other building materials, such as concrete or wood. They offer a cost-effective solution without compromising on quality or structural integrity. 4. Fire resistance: Steel angles have excellent fire resistance properties, making them a safer choice for construction. In the event of a fire, steel angles will not burn, warp, or emit toxic fumes, reducing the risk of structural collapse and providing more time for evacuation. 5. Sustainable and eco-friendly: Steel is one of the most recycled materials in the world. Using steel angles in construction promotes sustainability and reduces the demand for new steel production. Additionally, steel is 100% recyclable, ensuring minimal environmental impact. 6. Easy installation: Steel angles are lightweight and easily transported to the construction site, making them convenient for installation. Their ease of handling and quick assembly can help reduce construction time and labor costs. 7. Resistance to corrosion: Steel angles can be treated with protective coatings, such as galvanization, to enhance their resistance to corrosion. This ensures that the structure remains durable and maintains its structural integrity even in harsh environmental conditions. Overall, the advantages of using steel angles in construction include their strength, versatility, cost-effectiveness, fire resistance, sustainability, easy installation, and resistance to corrosion. These qualities make steel angles a popular choice for various construction projects, ranging from residential buildings to large industrial structures.

- Q: Can steel angles be used as handrails?

- Yes, steel angles can be used as handrails. Steel angles provide strength and stability, making them suitable for use as handrails in various settings such as stairs, ramps, balconies, and walkways. They can be welded or bolted securely to provide a reliable grip and support for individuals while navigating these areas.

Send your message to us

HOT ROLLED STEEL EQUAL ANGLE for construction JIS G3192

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches