LOG1100-A8 Injection Molding Machine QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG MACHINE

Model Number: LOG1100-A8

Place of Origin: China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 3751-6340 g

Clamping Force: 11000 kn

Opening Stroke: 1150 mm

Power(W): 45+45 kw

Certification: CE ISO9001

After-sales Service Provided: Engineers available to service machinery overseas

Voltage: 380V

Machine weight: 60T

Screw Diameter: 100-110-120-130 mm

Platen size: 1650*1650

Tie bar: 1150*1100

Ejector stroke: 350 mm

Ejector force: 270 kn

Heating power: 68.48 kw

Oil Tank Capacity: 2300 L

Dry cycle time: 10 Sec

Product Description

| Description | Unit | LOG-1100A8 | |||

| international recognized models | |||||

| injection | B | C | D | ||

| Tjeoretical injection volume | cm³ | 4123 | 4989 | 5938 | 6968 |

| Shot volume | g | 3751 | 4540 | 5403 | 6340 |

| Oz | 132.8 | 160.8 | 191.4 | 224.5 | |

| Screw diameter | mm | 100 | 110 | 120 | 130 |

| Injection diameter | mpa | 220 | 182 | 153 | 130 |

| Screw L:D ratio | 24.2:1 | 22:01 | 20.2:1 | 18.6:1 | |

| Scerw steoke | mm | 525 | |||

| Screw rotate speed | r/min | 0-110 | |||

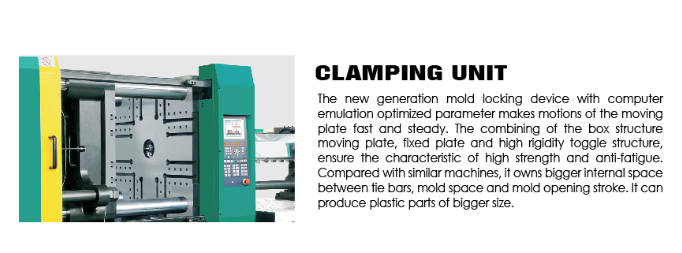

| CLAMPING UNIT | |||||

| Clamping force | kN | 11000 | |||

| Opening stroke | mm | 1150 | |||

| Platen size | mm*mm | 1650*1650 | |||

| Space between tie bars | mm*mm | 1150*1100 | |||

| Maldthickness | mm | 450-1200 | |||

| Platen Mix stroke | mm | 2350 | |||

| Ejection stroke | mm | 350 | |||

| Ejcetion force | kN | 270 | |||

| Power/Elcetric Heating | |||||

| Hydralic system pressure | Mpa | 17.5 | |||

| Pump motor | kw | 44+44 | |||

| Heating power | kw | 58.85 | |||

| Number of temp.conteol | 6+nozzle | ||||

| Other | |||||

| Cycle time | sec | 10 | |||

| Tank volume | L | 2300 | |||

| Machine dimesions | m*m*m | 12.5*2.8*3.5 | |||

| Weight of machine | kg | 60000 | |||

product 1

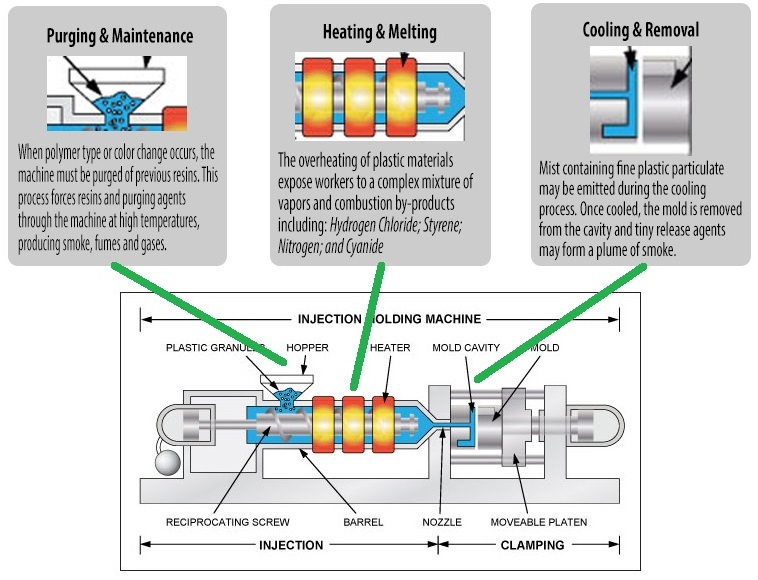

Common thermoplastic resins include:

Polyethylene PE

Polyvinyl Chloride PVC

Polypropylene PP

Polystyrene PS

Polyethlene Terephthalate PET

Acrylonitrile-butadiene-styrene ABS

Styrene-Acrylonitrile SA

Acrylic PMMA

Polyamide PA (Nylon)

Styrene-Acrylonitrile SAN

Polycarbonate PC

Packaging & Shipping

- Q: What is the fluctuation of the screw speed of injection molding machine?

- Screw speed adjustment of injection molding machineThe extruder screw speed and yield the direct proportion between tsuen. This shows that increasing the screw speed can greatly increase the extrusion yield, but from the angle of stable extrusion, it puts forward higher requirements for the control of screw speed fluctuation. The conventional single screw extruder mostly adopts the transmission mode of the ordinary V belt and gear change. Theoretical analysis shows that the elastic slip of the V belt occurs during the operation of l%-1.6% and causes the loss of rotation. Foreign high pin single screw extruder has adopted the direct connection of motor and reducer, and cancelled belt drive.Influence of type and control method of the motor on the extrusion process stability can not be ignored, at home and abroad in recent years extruder host using DC motor or motor, the motor electromagnetic speed compared with the previous working stability of these two kinds of machines has been greatly improved, the FV (vector volume) of AC variable frequency motor control represents the most the new transmission technology. Now, through the use of variable frequency speed regulation machine, with a special extruder for plastic extruder, the screw speed fluctuation can be controlled at about 0.01%.Dongguan Huahong Plastic Machinery Factory suggested that we should adopt it

- Q: How to debug the injection molding machine? solve

- You ask too many questions, and debugging involves so many things. If you mean that a process problem is not clear, or you can do other debugging on the injection machine, you can write it out. Plastic injection is not difficult. As long as you are willing to learn, you will not succeed if you depend on it

- Q: How to change the suction filter core of injection molding machine?

- This is simple,The first ready to stop operation of filter, filter box machine behind the clockwise turn can be replaced, not what skills

- Q: Every time the adhesive is stable, the glue is basically stable, but about 100 of the 2-3 die will not be in place, for example, the 50MM will stop

- Jin Xin offers you:Problems and solutions of the instability of screw spray:1, screw head, check ring, backstop, ring, screw, cylinder wear. Method: update worn parts.2, screw, cylinder impurities. Method: clean up.3 、 the inner ring of the injection oil cylinder is damaged and the inner leakage is produced. Method: renew sealing ring.4 、 the temperature control of the heating cylinder is unstable. Methods: to improve the accuracy of electronic control temperature control.5, the system pressure and speed control part of the abnormal. Methods: check whether the preset pressure is stable and whether the holding pressure is constant. Exhaust, improve the cleaning circuit, change ratio valve, motor, master control program and so on.6, the composition of the material is not uniform. Methods: to check whether plastic products reached the performance and molding conditions.7, the storage screw speed is not stable. Methods: check whether the feeding motor is working properly and whether the system flow is fluctuating.8 、 loosening the position gauge of the injection device. Method: fasten and reset the position gauge.

- Q: Can you tell me if there are 350 grams of three injection molding machines? How much? Thank you

- 168 tons, theoretical injection weight: A--335 grams, B--378 grams

- Q: Seek advice! Is there a better low-pressure injection molding machine? After the sale well, which friends can introduce, thank you!

- Let me introduce you to a good oneChasing the answerAs far as I know, the low pressure injection molding machine produced by Connie Technology Co., Ltd. is especially good and provides full range of technical support, which is rich in New Technology

- Q: We are going to an injection molding machine factory at once. I don't know yet which is what I learn, NC, please master, and hope to be able to put the knowledge about injection molding machine told me, I appreciate the injection molding machine is that NC programming ah | please master, thank you

- Injection molding machine can not be programmed, mainly the use of operations, adjustment, parameter settings, etc.

- Q: What is the best brand of injection molding machine?

- Domestic Haitian, Donghua, Huada, all can. Foreign Demag, Ube.

- Q: Why should the central feed system be used in the injection molding workshop?

- The advantage of using the central feed system in the injection molding workshop is that:1. save energy2. save labor costs3. improve the company's overall image4. keep the factory environment clean and tidy5., centralized management of raw materials to avoid waste of raw materials and pollution6., can isolate the main transmission, reduce noise pollution"Dongguan niasi" the central feeding system adopts the vacuum conveying mode, through the pipeline system will focus on plastic raw materials from the storage tank is transferred to the central dehumidification system will then transport the raw material after drying to each injection molding machine. "Dongguan niasi" the central feeding system adopts "design a machine of a pipe", to ensure the whole system of raw materials for air transport, to prevent the resurgence of the raw material after drying dehumidifying. At the same time, the pipeline can be cleaned up after each conveying cycle to ensure that there is no residual granular material in the pipeline. The material performance of the injection molding machine is guaranteed to be consistent while avoiding the resurgence of the raw material. Under the vacuum negative pressure, the dust in the raw material will be filtered out through the dust filtration system, which will help to improve the quality of the molding products.Please refer to the resources below for a detailed example of the central feeding system!!!

- Q: What is the meaning of injection molding machine before melting and pumping and after melting? What's the function of 10?

- Before the pumping molten refers to the pumping action in the melt before the start, to remove the injection pressure in the cylinder head, the buildup of pressure; pumping molten refers to the pumping action in the melt after the end to relieved some of the pressure generated by the melt.The pumping action is not necessary, generally set according to the nature of raw materials, no salivation phenomenon is not used.

Send your message to us

LOG1100-A8 Injection Molding Machine QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords