Injection molding machine LOG-1100S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Condition: | New | Type: | Tube Head Injection | Style: | Horizontal |

| Brand Name: | LOG | Model Number: | LOG-1100S8 | Place of Origin: | Zhejiang, China (Mainland) |

| Plastic Type: | Thermoplastic | Automatic: | Yes | Injection Weight: | 5403 |

| Clamping Force: | 11000KN | Opening Stroke: | 1150mm | Certification: | CE |

| After-sales Service Provided: | Engineers available to service machinery overseas | BIG shot weight: | energy saving |

Packaging & Delivery

| Packaging Details: | one machine in three 40GP containers |

| Delivery Detail: | 45days |

Product Description

Product performance and advantages:

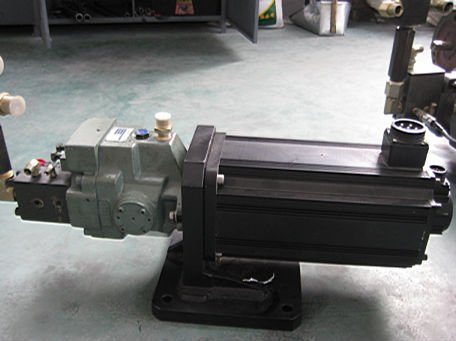

1. Servo energy-saving system

Using the servo motor oil electricity composite structure

2. Servo motor high response feature

It costs only 0.05s for servo energy saving injection molding machines to achieve the maximum output, in

comparison with conventional hydraulic injection molding machines. The response speed has been obviously

increased, improving the production efficiency.

3. Unique function

Large colored screen with TFT interface

Full automatic close-loop control

Module design of hardware

Auto-tune PID temperature control

Pc interface USB, PIC, and FLASH…

Curve monitoring and analysis function

K-can data transmission (500Kbit/s)

On-line central monitoring function

LOG-1100S8 Technical parameters

Description | Unit | LOG-1100S8 | |||

international recognized models | |||||

injection | B | C | D | ||

Tjeoretical injection volume | cm³ | 4123 | 4989 | 5938 | 6968 |

Shot volume | g | 3751 | 4540 | 5403 | 6340 |

Oz | 132.8 | 160.8 | 191.4 | 224.5 | |

Screw diameter | mm | 100 | 110 | 120 | 130 |

Injection diameter | mpa | 220 | 182 | 153 | 130 |

Screw L:D ratio | 24.2:1 | 22:1 | 20.2:1 | 18.6:1 | |

Scerw steoke | mm | 525 | |||

Screw rotate speed | r/min | 0-110 | |||

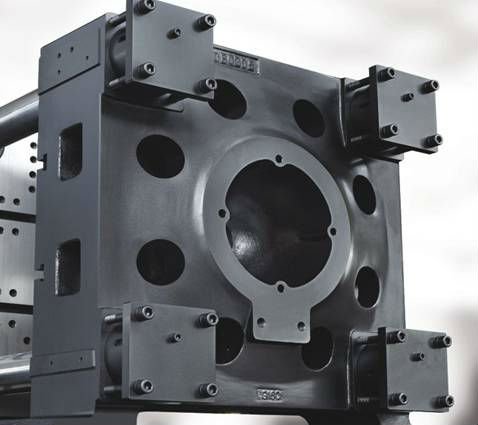

CLAMPING UNIT | |||||

Clamping force | kN | 11000 | |||

Opening stroke | mm | 1150 | |||

Platen size | mm*mm | 1650*1650 | |||

Space between tie bars | mm*mm | 1150*1100 | |||

Maldthickness | mm | 450-1200 | |||

Platen Mix stroke | mm | 2350 | |||

Ejection stroke | mm | 350 | |||

Ejcetion force | kN | 270 | |||

Power/Elcetric Heating | |||||

Hydralic system pressure | Mpa | 17.5 | |||

Pump motor | kw | 44+44 | |||

Heating power | kw | 58.85 | |||

Number of temp.conteol | 6+nozzle | ||||

Other | |||||

Cycle time | sec | 10 | |||

Tank volume | L | 2300 | |||

Machine dimesions | m*m*m | 12.5*2.8*3.5 | |||

Weight of machine | kg | 60000 | |||

- Q: Injection molding machine barrel temperature is not very high at normal and low temperature line is very tight no problem

- Or the temperature line problems, sometimes without induction to the actual temperature will appear this phenomenon. Try a few more adjustments with your hands

- Q: Injection molding machine melt when the screw speed is particularly slow, what is the reason for the oil pound pressure is small?

- 1. check how much screw speed is set when the injection machine is set2. is the temperature setting reasonable? If the solution temperature (barrel temperature) is unreasonable, and the fluidity of the compound is not good, it will appear because of friction, speed is very slow.The above should be the oil pump problem

- Q: What kinds of oil are used in the injection molding machine?

- Look at it!. Spring and autumn days with 46# anti-wear hydraulic oil; but the general urban use 46# throughout the year to use, where you don't have much low temperature, in accordance with the standard conditions for winter 32# antiwear hydraulic oil, if there is a gear box to use gear oil.The main tank is mainly provided to meet the normal operation of the hydraulic system required flow, mainly with hydraulic oil, heat distribution,I contact the manufacturers are generally the Great Wall L-HM46#, anti-wear hydraulic oil consumption is relatively large. For hydraulic system lubrication and work, as well as other parts of the bearing grease, large tonnage models, which is related to the design of the oil circuit. Ask them how the hydraulic oil is used in the equipment. It is used for lubrication and work in the hydraulic system,

- Q: What are the famous brands of injection molding machines?

- There are Chun, Haida, Haitai, Ge, Hai Fei, Bo, YIZUMI, ohplasSouth Korea, LG, Canada, HUSKY, Taiwan

- Q: Please tell me the reason for choosing this tonnageFor example, an injection molding machine, water flow of 4 tons per hour, then 4 units on the election of 20T cooling tower is not enough? 20T's cooling water flow is about 18 cubic meters per hour

- In general we 160T mold, pipe size of 16MM-20MM in diameter, but in general we pump flow rate Straw at 2 m / S (injection cooling water is recycled, water pump Straw flow is the decision point need air conditioning cooling tower), so we can assume that the size of pipe diameter is 20MM, the water flow rate of 2 meters so every hour per second; each injection molding machine needs the amount of water:PI (0.01 meters) * (0.01 meters) *2 M / s *3600 s =2.26 cubic metersYou do this, and here you should be clear! In addition, individuals feel that there is still need to consider whether the subsequent expansion of production, that is, increase the number of injection molding machine, so personally feel that the need to reserve space as well!

- Q: What is the V-P conversion in injection molding machine?

- V-P switching point, that is, to that location, from speed to pressure switch

- Q: RTBrother recently understand the injection mold related knowledge, about the forming cycle of this problem, I do not know whether this cycle can be estimated according to the relevant parameters, please advise!Forming cycle: the time between the previous product and the next product, including the time taken by the manipulator, and so on. I am for the new quotation, not too precise, but not too far away, trouble expert advice, small first, thank you very much!

- If a trial can be used to test out the stopwatch + wide release time, not the trial production of new software available for calculation, but the structure of a product cycle also depends on the size and thickness of the product, is complex and molding technology to all of these affect the product cycle, your statement is not very clear and it is difficult to give you a more accurate estimate of the cycle, experienced personnel can structure size, thickness, the product was estimated, and more reasonable!

- Q: Relative to the size of the installation mold, it can also be said to be the internal column or guide column of the injection molding machine. How can this part be translated in English?

- Tie Bars--- pull rod (Ge Linzhu)Clearamce Between Tie Bars is the column spacing is between the Green column, you said the distance, Green column spacing also restricted the installation of the width of the mold, the mold width must be less than the Green column spacing can be put under the lock on shot out!

- Q: How to choose an injection molding machine

- The selection of injection molding machine is usually made by the following parameters, for reference.1: modulus of capacity, that is, the maximum plastic mold size that can be placed.2: amount of material is melt, maximum amount of glue tube can shoot a glue, injection molding products of the first mock exam should not exceed the total amount of 70% melts.3: clamping force, with reference to the largest product surface area, the maximum injection pressure, the mold can not open the clamping force.

- Q: What is the injection molding machine?

- An injection molding machine is a mechanical device that fills a plastic into plastic!!

Send your message to us

Injection molding machine LOG-1100S8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords