Heavy Duty Whole Steel Formwork for Bridge Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

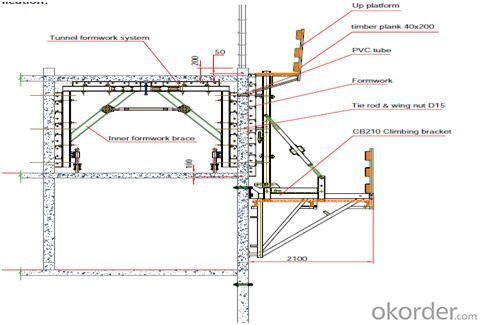

1. Structure of Heavy Duty Whole Steel Formwork

A compositional steel formwork system mainly used in the building which has regular structure without beams, the excellent formwork system can make the integral pouring for the wall & slab easily achieved.

2. Main Features of Heavy Duty Whole Steel Formwork

◆ High stiffness, make perfect shape for concrete.

◆ Easy operation, save labor and force.

◆ Fast forming, repeatedly turnover.

◆ No assembling, easy operation with formed formwork.

◆ High stiffness, make perfect shape for concrete.

◆ Repeatedly turnover is available.

◆ Widely applied range, such as building, bridge, tunnel, etc.

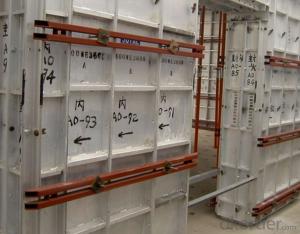

3. Heavy Duty Whole Steel Formwork images

4. Heavy Duty Whole Steel Formwork Specifications

5. FAQ of Heavy Duty Whole Steel Formwork

1) What can we do for you?

.We can ensure the quality of the Heavy Duty Whole Steel Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q: What are the different types of access solutions available for steel formwork?

- There are several different types of access solutions available for steel formwork, depending on the specific requirements of the construction project. Some of the common access solutions include: 1. Ladder Access: This is the most basic and commonly used access solution for steel formwork. Ladders are attached to the formwork structure, allowing workers to climb up and down easily. Ladder access is simple, cost-effective, and suitable for low-rise structures. 2. Stair Access: For taller structures, stair access is a safer and more convenient option. Stairs can be attached to the steel formwork, providing a stable and secure pathway for workers to move between different levels. Stair access is particularly useful in high-rise buildings or projects with multiple levels. 3. Platform Access: Platforms are often used in conjunction with ladders or stairs to provide a wider working area. These platforms can be fixed or movable, allowing workers to access various parts of the steel formwork system easily. Platforms provide a stable and safe working surface, enhancing productivity and safety on the construction site. 4. Scaffold Access: Scaffold systems are commonly used for construction projects and can also be utilized for accessing steel formwork. Scaffold access provides a flexible and adjustable solution, allowing workers to reach different heights and areas of the formwork structure. Scaffold access is particularly useful for complex projects or projects with irregular shapes. 5. Crane Access: In some cases, large steel formwork panels or structures may require the use of cranes for access. Cranes can lift workers to the desired height, providing a quick and efficient access solution. Crane access is often used for heavy-duty formwork systems or projects with large-scale structures. In summary, the different types of access solutions available for steel formwork include ladder access, stair access, platform access, scaffold access, and crane access. The choice of access solution depends on factors such as the height and complexity of the structure, as well as the specific requirements of the construction project.

- Q: How does steel formwork affect the overall flexibility of the structure?

- A positive impact on the overall flexibility of a structure can be achieved through the use of steel formwork. Unlike traditional timber formwork, steel formwork is recognized for its strength, durability, and rigidity. These characteristics enable the construction of structures that are more robust and stable. The utilization of steel formwork enhances flexibility in terms of design and construction. Steel formwork systems are extremely adaptable and can be easily adjusted and modified to meet various project requirements. This adaptability allows for the development of intricate shapes and structures, including curved walls, while maintaining overall strength and stability. Furthermore, steel formwork offers a higher load-bearing capacity compared to alternative formwork materials. This increased strength permits the construction of taller and more expansive structures. The rigidity of steel formwork also reduces deflection and deformation, ensuring the structural integrity of the building. Moreover, steel formwork is renowned for its reusability. Unlike other formwork materials, steel formwork can be employed multiple times, resulting in a cost-effective solution. The reusability factor also contributes to the overall flexibility of the structure, as it facilitates easy dismantling and reassembly, allowing for any necessary modifications or renovations in the future. In conclusion, the strength, durability, and adaptability of steel formwork significantly enhance the overall flexibility of a structure. Its ability to handle complex designs, higher loads, and its reusability make it an ideal choice for construction projects, providing a solid foundation for creating flexible and resilient structures.

- Q: What are the common design considerations for steel formwork in marine environments?

- Some common design considerations for steel formwork in marine environments include corrosion resistance, durability, strength, and stability. Steel formwork used in marine environments should be made from corrosion-resistant materials, such as stainless steel or galvanized steel, to prevent degradation due to exposure to saltwater. It should also be designed to withstand harsh weather conditions, including high winds and waves, to ensure its longevity. Additionally, the formwork should have sufficient strength and stability to support the weight of concrete and withstand the forces exerted by the marine environment. Proper sealing and maintenance of the formwork are also vital to prevent water infiltration and maintain its effectiveness.

- Q: How does steel formwork handle different concrete strength requirements?

- Steel formwork proves to be a highly versatile and durable solution, capable of effectively managing a wide range of concrete strength demands. Concrete strength is influenced by its mixture proportions, curing conditions, and the quality of materials employed. By providing a reliable and secure framework for pouring concrete, steel formwork plays a pivotal role in fulfilling these requirements. One notable advantage of steel formwork lies in its ability to withstand the immense pressures and strong vibrations encountered during concrete pouring and compaction. This becomes particularly crucial when dealing with high-strength concrete, as it necessitates greater force application to attain the desired density and durability. Thanks to its structural integrity and rigidity, steel formwork can bear these forces without deformations or failures, consequently ensuring a consistent and uniform distribution of the concrete. Another key benefit of steel formwork is its flexibility in terms of shape and size, allowing for customization to accommodate diverse concrete strength specifications. This versatility facilitates the construction of various structural elements, including columns, beams, walls, and slabs, each with unique strength requirements. Additionally, steel formwork can be effortlessly assembled and disassembled, making it adaptable to different projects and enabling the reuse of formwork components. Moreover, steel formwork imparts a smooth and precise finish to the concrete surface, a crucial factor in achieving desired aesthetics and functionality. This is particularly important for architectural or decorative concrete, where a high-quality finish is imperative. The smooth and flat surface provided by steel formwork ensures even curing of the concrete and minimizes the risk of surface defects. To summarize, steel formwork is well-suited to handle diverse concrete strength requirements due to its robustness, durability, adaptability, and ability to deliver a smooth finish. Its strength and flexibility make it an ideal choice for construction projects demanding varying concrete strengths, guaranteeing the successful execution of diverse structural designs and meeting performance expectations.

- Q: How does steel formwork affect the overall energy efficiency of a structure?

- Steel formwork can have a significant impact on the overall energy efficiency of a structure. Firstly, steel formwork is known for its durability and strength, which allows it to be reused multiple times. This reusability reduces the need for new formwork materials, thereby minimizing waste generation and conserving resources. By reducing the amount of waste produced during construction, the overall environmental impact is reduced, leading to improved energy efficiency. Additionally, steel formwork offers excellent thermal properties. It has a high thermal mass, meaning it can absorb and store heat energy effectively. This characteristic helps regulate the temperature inside the structure, reducing the reliance on heating or cooling systems. By stabilizing the internal temperature, the energy consumption for climate control is reduced, resulting in improved energy efficiency and lower operational costs. Furthermore, steel formwork enables the construction of energy-efficient designs. Its versatility allows for complex shapes and configurations, facilitating the integration of energy-saving elements such as insulation, ventilation systems, and renewable energy technologies. These features contribute to the overall energy performance of the structure, enhancing its efficiency and sustainability. Overall, steel formwork positively impacts the energy efficiency of a structure by reducing waste, providing excellent thermal properties, and enabling energy-efficient designs. By utilizing steel formwork, construction projects can achieve higher levels of sustainability and contribute to a greener and more energy-efficient built environment.

- Q: Can steel formwork be used for projects with limited formwork assembly time?

- Projects with limited formwork assembly time can indeed utilize steel formwork. Renowned for its durability and strength, steel formwork proves to be an apt choice for projects necessitating swift assembly and demobilization. In contrast to conventional timber formwork, steel formwork offers effortless assembly and disassembly, thereby reducing overall construction duration. Furthermore, steel formwork's reusability facilitates cost savings and heightened efficiency for subsequent projects. In summary, steel formwork emerges as a dependable resolution for projects with restricted formwork assembly time.

- Q: How does steel formwork help in achieving a high-quality finish?

- Steel formwork helps in achieving a high-quality finish due to its ability to provide a strong and rigid structure for concrete placement. Its smooth and non-absorbent surface prevents the formation of air bubbles, resulting in a smooth and even finish. Additionally, steel formwork allows for precise and accurate shaping and alignment, ensuring the desired dimensions and contours of the final concrete product.

- Q: How does steel formwork affect the overall stability of a structure?

- Steel formwork has a significant impact on the overall stability of a structure. Formwork refers to the temporary molds or frameworks used to shape and support wet concrete until it hardens and becomes self-supporting. Steel formwork, in particular, offers several advantages that positively influence the stability and strength of the structure. Firstly, steel formwork provides exceptional strength and durability compared to other materials like wood or plastic. This high strength allows steel formwork to withstand the pressure exerted by the wet concrete without deformation or collapse. Consequently, the structure's stability is enhanced as the formwork maintains its shape and rigidity during the concrete pouring and curing process. Moreover, steel formwork offers better dimensional accuracy and consistency. Its rigidity prevents any movement or shifting, ensuring that the concrete is poured and cured in the desired shape and dimensions. This precision is crucial for maintaining the structural integrity and stability of the final construction. Additionally, steel formwork allows for greater flexibility in design and construction. It can be easily customized and shaped to meet the specific requirements of the structure, enabling architects and engineers to create complex and unique designs. This flexibility enhances the overall stability of the structure by allowing for efficient load distribution and reinforcement placement. Furthermore, steel formwork possesses excellent load-bearing capacity. It can efficiently distribute the weight of the wet concrete, as well as any additional loads applied during construction, such as workers, equipment, or construction materials. This load-bearing capacity ensures that the structure remains stable and can withstand the imposed loads without compromising its integrity. Lastly, steel formwork has a longer lifespan compared to other formwork materials. Its durability and resistance to deterioration increase the overall stability of the structure over time. Steel formwork can be reused multiple times, reducing waste and costs while maintaining the desired stability and quality of the finished construction. In conclusion, steel formwork significantly contributes to the overall stability of a structure. Its strength, dimensional accuracy, flexibility, load-bearing capacity, and longevity ensure that the formwork maintains its shape and rigidity, supporting the wet concrete and allowing it to cure properly. By providing a solid and reliable foundation, steel formwork enhances the stability and strength of the structure, ensuring its long-term durability.

- Q: Is steel formwork suitable for all types of concrete structures?

- Steel formwork is generally considered to be suitable for a wide range of concrete structures. However, its suitability may depend on several factors such as the design requirements, budget, and project timeline. Steel formwork offers several advantages over other types of formwork systems. It is known for its high strength and durability, which allows it to withstand the pressure exerted by the fresh concrete without warping or deforming. This makes it particularly suitable for structures that require large concrete pours or have complex geometries. Moreover, steel formwork provides excellent dimensional accuracy, ensuring that the final concrete structure meets the required specifications. It also allows for easy customization, enabling the formwork to be tailored to the specific needs of the project. However, there are instances where steel formwork may not be the most suitable option. For example, if the budget is limited, steel formwork may be more expensive compared to alternatives such as timber or plastic formwork. Additionally, if the project has a tight schedule, steel formwork may require more time for fabrication and assembly compared to other systems. Furthermore, steel formwork may not be the best choice for structures that have strict aesthetic requirements. The steel panels may leave imprints on the concrete surface, which may not be desirable in certain architectural designs. In conclusion, while steel formwork is generally suitable for a wide range of concrete structures, its suitability may vary based on project-specific factors such as design requirements, budget, and timeline. It is important to carefully evaluate these factors before deciding on the most appropriate formwork system for a particular project.

- Q: How does steel formwork affect the overall productivity of the construction process?

- Steel formwork can have a significant impact on the overall productivity of the construction process. Firstly, steel formwork is known for its durability and strength, allowing it to withstand the high pressures and forces exerted by concrete during the pouring and curing stages. This durability ensures that the formwork remains intact and stable, reducing the need for repairs or replacements, thus saving time and cost. Moreover, steel formwork offers increased efficiency in terms of assembly and disassembly. Steel panels can be easily connected and detached, allowing for quick and smooth installation and removal. This ease of use ensures that the construction process can progress at a faster pace, increasing overall productivity. Additionally, steel formwork provides a smooth and high-quality finish to concrete structures. The precise and rigid nature of steel formwork prevents any deformations or warping during the pouring and curing stages, resulting in a superior surface finish. This eliminates the need for additional finishing work, such as plastering or smoothing, thereby reducing the time and effort required for post-construction tasks. Furthermore, steel formwork is highly adaptable and can be customized to fit various shapes and sizes, enabling the construction of complex structures with ease. This flexibility allows for greater design freedom and eliminates the need for additional supporting structures, reducing construction time and increasing productivity. Lastly, steel formwork is reusable and can be used for multiple projects, unlike traditional timber formwork which often needs to be discarded after a single use. This reusability not only reduces material waste but also saves time and cost in procuring new formwork for each project. In conclusion, steel formwork significantly enhances the overall productivity of the construction process. Its durability, ease of assembly, high-quality finish, adaptability, and reusability all contribute to faster construction timelines, reduced costs, and improved efficiency, making it a preferred choice for many construction projects.

Send your message to us

Heavy Duty Whole Steel Formwork for Bridge Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords