Large Sheets of Aluminum Coil 5754 5005 8079 8011 1050 1060 for Cans

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Pattern: orange peel, aluminum sheet5 bar,half a ball,diamond,compass shape

1.Orange peel aluminum sheet/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052

2)Temper :0 H114 H24 H32

3) Specification thickness:0.2mm-3.0mm

width:50mm-1300mm

Length: according your request

4)Application: Refrigeration. Air-conditioner. keep warm well such as pipe ,tank

5)Surface: No crack,canker, hole

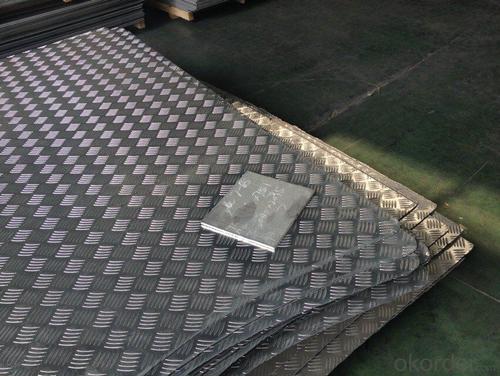

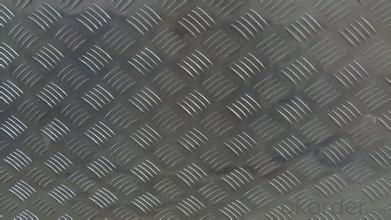

2. aluminum sheet5 bar/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

3.Compass shape aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: thickness:1.0mm-10mm

width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

4.Diamond aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: building industry,packing,decorative

5)Surface: No crack,canker, hole

4) Delivery time: 15-20 days after confirming order.

For all above:

1) Minimum order quantity: 5 tons per size.

2) The term of payment: T/T, irrevocable L/C at sight.

3) Packing: Export standard, waterproof wooden,craft,plywood pallet,etc.

- Q: Are the aluminum sheets suitable for manufacturing aircraft fuselages?

- Indeed, the utilization of aluminum sheets is appropriate for the production of aircraft fuselages. Aluminum remains a favored selection for aircraft assembly owing to its exceptional strength-to-weight proportion, ability to withstand corrosion, and simplicity in fabricating. Its lightweight nature aids in the reduction of the aircraft's total weight, thereby enhancing fuel efficiency and augmenting payload capacity. Moreover, aluminum exhibits remarkable resilience in enduring the pressures and tensions encountered during flight. Furthermore, it is a readily accessible and economically viable material, rendering it a pragmatic preference for aircraft manufacturers.

- Q: Can the aluminum sheets be used for soundproofing applications?

- Yes, aluminum sheets can be used for soundproofing applications. Aluminum is a good conductor of sound, but when used in combination with other sound-absorbing materials or in soundproofing structures, it can effectively reduce noise transmission.

- Q: How much is the aluminum plate with a thick 2mm 1000*2000? Thanks

- (the current price of aluminum ingot is about: 15000 yuan / ton, plus board processing fee 2000/ tons, =18000 yuan / ton), the proportion of 2.71*3mm* aluminum plate price 18 yuan / kg, =146.34 yuan / square. 2MM*2.71* price 18 yuan =97.26 yuan / square.

- Q: Can aluminum sheets be used for electrical conductors?

- Yes, aluminum sheets can be used for electrical conductors. Aluminum is a good conductor of electricity and is commonly used in various electrical applications such as wiring, cables, and power transmission lines.

- Q: Does aluminum foil keep food warm or cool, or is it just a convenient material to cover food with?

- all i know is that it keeps food hot.

- Q: What are the different surface treatments for aluminum sheets to improve corrosion resistance?

- There are several surface treatments available for aluminum sheets that can significantly enhance their corrosion resistance. These treatments include: 1. Anodizing: Anodizing is a widely used surface treatment for aluminum sheets. It involves immersing the aluminum in an electrolyte solution and applying an electric current. This creates a protective oxide layer on the surface of the aluminum, which improves its corrosion resistance. 2. Chromate Conversion Coating: Chromate conversion coating, also known as chemical film or chromating, is another common treatment for aluminum sheets. It involves immersing the aluminum in a solution containing chromate compounds. This forms a thin layer of chromate on the surface, which acts as a barrier against corrosion. 3. Powder Coating: Powder coating is a dry finishing process where a powdered polymer is sprayed onto the aluminum surface and then cured under heat. This creates a durable and corrosion-resistant coating that provides excellent protection against environmental factors. 4. E-coating: Electrophoretic coating, or e-coating, is an immersion-based process in which the aluminum sheet is submerged in an electrically charged paint bath. This attracts the paint particles to the surface, creating a uniform and corrosion-resistant coating. 5. Cladding: Cladding involves bonding a layer of a different metal, such as stainless steel or zinc, to the aluminum sheet's surface. This creates a protective barrier that shields the aluminum from corrosion. 6. Organic Coatings: Applying organic coatings, such as acrylic or polyester paints, to the aluminum surface can provide an effective corrosion-resistant barrier. These coatings form a protective film that prevents moisture and corrosive substances from reaching the aluminum. It is important to note that the choice of surface treatment depends on various factors, including the specific application, environmental conditions, and desired appearance. Some treatments may be more suitable for certain industries or environments, so it is advisable to consult with professionals to determine the most appropriate treatment for a particular application.

- Q: Are aluminum sheets easy to work with?

- Yes, aluminum sheets are generally easy to work with. Aluminum is a lightweight and malleable metal, which makes it easier to cut, shape, and manipulate compared to other metals. It can be easily bent, formed, and welded, allowing for various fabrication techniques. Additionally, aluminum sheets have good corrosion resistance, which further adds to their ease of use. Whether it is for constructing lightweight structures, fabricating parts, or creating intricate designs, aluminum sheets provide versatility and convenience in many applications.

- Q: The real bumper/ reinforcement bar that is behind the plastic bumpers. Magnet don't stick to it and it don't rust which both types of metal are pretty much like that.

- i agree, the main bumper support under the plastic bumper skin, is aluminum.

- Q: What are the fire resistance properties of aluminum sheets?

- Aluminum sheets exhibit excellent fire resistance properties due to their high melting point and low thermal conductivity. Aluminum has a melting point of approximately 660 degrees Celsius, which is significantly higher than other commonly used metals like steel. This means that aluminum sheets can withstand high temperatures without melting or losing their structural integrity. Additionally, aluminum has a low thermal conductivity, which means it does not transfer heat easily. This property helps to prevent the spread of fire and limits the heat transfer to adjacent areas. Moreover, aluminum does not produce toxic gases or emit hazardous fumes when exposed to fire, making it a safe material in fire-prone environments. These fire-resistant properties make aluminum sheets a popular choice for various applications where fire safety is a concern, such as in the construction of aircraft, buildings, and automotive components.

- Q: My new home has a mix of copper and aluminum wiring. My mother used a shop vac in one of the recepticles last week and blew two of them in my bedroom. Then this weekend my brother was replacing my exhaust fan in the bathroom and that proceeded to blow the entire bedroom and bathroom including ceiling fans, lights and all recepticles. Does anyone have any ideas?

- Home Depot sells quality aluminium receptacles. Not doubting your father totally but an electrician needs to check the inside of the panel. A number of things can go and the breaker wont be effected. If the problem is not within the panel an electrician can trace the dead circuits and isolate the problems. Hopefully your new but old home does not have any concealed electrical boxes. Sometimes in older homes the previous owner may have added some electrical items and any Joe could have did it. Believe me I've seen a lot in my 15 years of practice.

Send your message to us

Large Sheets of Aluminum Coil 5754 5005 8079 8011 1050 1060 for Cans

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords