1070 Aluminum Coil for Sale - Aluminium Coil Sheet in 1100, 3003, 5052, 5754

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

Aluminum is a versatile material integral to modern life. The metal is found in everything from soda cans to cell phones to window frames to airplanes. The process for making the aluminum that goes into these products is found in the pages within the Industries section. Details about end use products are found in the Product Markets section. To learn more about each stage of the aluminum process, click on the icons below

3. Feature of Aluminum

In 1954, there were 75 registered aluminum alloys. Today, there are more than 530 registered active compositions and that number continues to grow. That underscores how versatile and ubiquitous aluminum has become in our modern world. So what are aluminum alloys and why are they important?

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

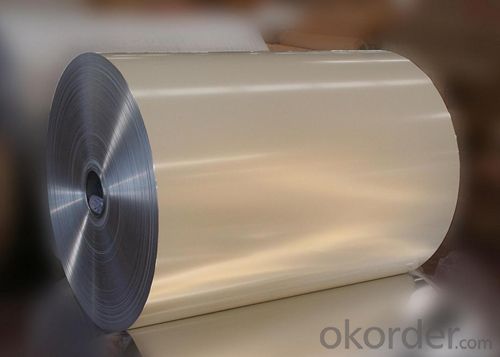

5. Image of Aluminum

6. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: like i need a good slogan for aluminum its for a school project like for arsenic's is Arsenic's a sure fire way to deal with a rat, It works better than a mean old cat!

- Aluminium's the stuff in bicycles, And cans and planes and recyclables! Hope you liked that! 3, phantasmal.spirit

- Q: What are the common sizes of aluminum coils?

- The common sizes of aluminum coils can vary depending on the specific industry and application. However, some commonly used sizes include widths ranging from 36 inches to 72 inches, with thicknesses typically ranging from 0.019 inches to 0.125 inches.

- Q: I know aluminum has 3 valence electrons and oxygen has 7, but if anyone could explain the chemical formula to me it would be great.

- The chemical formula of aluminium oxide is Al2O3 An aluminium ion has a 3+ charge, because it loses 3 electrons when it reacts. An oxygen ion has a 2- charge, because it gains 2 electrons when it reacts. In aluminium oxide, the charges of the ions need to cancel out. So... 2 aluminium ions -- 6+ total charge , 3 oxygen ions -- 6- total charge The charges cancel out.

- Q: Are aluminum coils suitable for food storage containers?

- Yes, aluminum coils are suitable for food storage containers. Aluminum is a non-toxic and non-reactive metal that is safe for storing food. It is lightweight, durable, and has excellent temperature retention properties, making it a popular choice for food storage containers.

- Q: How are aluminum coils inspected for quality control?

- Aluminum coils are inspected for quality control through a combination of visual inspections and various non-destructive testing methods. These measures ensure that the coils meet the required specifications and are free from any defects or flaws. Visual inspections involve trained personnel carefully examining the coils for surface defects such as scratches, dents, or any irregularities in shape or size. The inspectors also check for any signs of contamination, oxidation, or discoloration. Any abnormalities detected during this visual inspection are noted and addressed accordingly. In addition to visual inspections, non-destructive testing techniques are employed to evaluate the internal quality of the aluminum coils. One commonly used method is ultrasonic testing, where high-frequency sound waves are transmitted through the coils. The reflected sound waves are analyzed to identify any internal defects like voids, cracks, or delaminations. This technique allows for a thorough assessment of the coil's integrity without causing any damage to the material. Another non-destructive testing method used for quality control is eddy current testing. This technique involves inducing electrical currents in the coils and measuring the resulting magnetic fields. Any variations in the magnetic fields can indicate flaws or defects in the aluminum, such as cracks or inclusions. Eddy current testing is particularly effective in detecting surface defects and discontinuities. Furthermore, measurements of important physical properties like thickness, width, and flatness are taken to ensure they meet the required standards. This is typically done using specialized instruments such as micrometers, calipers, or laser scanners. Overall, the inspection of aluminum coils for quality control involves a combination of visual inspections and non-destructive testing techniques to ensure that the coils are free from defects, meet the required specifications, and are of high quality.

- Q: This question asks about the environmental impact of aluminum coils, which are commonly used in various industries.

- <p>Aluminum coils have both positive and negative environmental impacts. On the positive side, aluminum is highly recyclable, and its use in coils reduces the need for raw material extraction, thus conserving natural resources. The recycling process also consumes less energy compared to primary aluminum production, reducing greenhouse gas emissions. However, the production of aluminum coils involves energy-intensive processes that can contribute to carbon emissions. Additionally, if not properly managed, the waste from aluminum production can pollute water bodies and soil. Overall, the environmental impact depends on the balance between recycling and production practices, as well as waste management.</p>

- Q: What are the different coil lengths available for aluminum coils?

- There are several different coil lengths available for aluminum coils, depending on the specific application and requirements. Generally, aluminum coils can be found in lengths ranging from a few feet to several hundred feet. The most common coil lengths for aluminum coils used in various industries, such as HVAC, automotive, and construction, are typically 50 feet, 100 feet, and 250 feet. However, it's important to note that custom coil lengths can also be manufactured based on the specific needs of the customer. These custom lengths can vary depending on factors like coil thickness, width, and intended use. Ultimately, the available coil lengths for aluminum coils are flexible and can be tailored to suit the needs of different industries and applications.

- Q: What are the different surface finishes for pre-painted aluminum coils?

- There are several different surface finishes available for pre-painted aluminum coils. These finishes are applied to the aluminum surface to enhance its appearance, durability, and resistance to external factors. Some of the common surface finishes for pre-painted aluminum coils include: 1. Polyester (PE) Finish: This is the most widely used surface finish for pre-painted aluminum coils. It offers good durability, weather resistance, and color retention. Polyester finishes are available in a wide range of colors and gloss levels. 2. Polyvinylidene Fluoride (PVDF) Finish: PVDF coatings provide excellent resistance to weathering, UV radiation, and chemical exposure. These finishes are highly durable and maintain their color and gloss for extended periods. PVDF finishes are often used in architectural applications where color retention and longevity are important. 3. Polyurethane (PU) Finish: Polyurethane coatings offer good resistance to abrasion, chemicals, and weathering. They provide a smooth and glossy appearance and are available in a wide range of colors. PU finishes are commonly used in applications that require high durability and resistance to outdoor conditions. 4. Epoxy (EP) Finish: Epoxy coatings provide excellent chemical resistance and adhesion. They are often used in industrial applications where corrosion resistance is crucial. Epoxy finishes can be combined with other coatings, such as polyester or PVDF, to enhance their performance. 5. Acrylic (AC) Finish: Acrylic coatings offer good weather resistance and color retention. They are often used in architectural applications where aesthetics and durability are important. Acrylic finishes provide a glossy appearance and are available in a wide range of colors. These are just a few examples of the different surface finishes available for pre-painted aluminum coils. The choice of finish depends on the specific requirements of the application, including the desired appearance, durability, and resistance to external factors.

- Q: Are aluminum coils suitable for food and beverage packaging?

- Yes, aluminum coils are highly suitable for food and beverage packaging. Aluminum is a safe and durable material that helps protect the quality and freshness of food and beverages. It is non-toxic, corrosion-resistant, and provides an effective barrier against moisture, oxygen, and light. Additionally, aluminum coils are lightweight, easily moldable, and can be easily shaped into various packaging formats, making it a popular choice for the food and beverage industry.

- Q: When they say to coat entire roof system with Aluminum coating, what does that mean? The area to coat is NOT the ceramic barrel tiles of a roof but the flat section covered with tar paper and granules of shiny sand. Is it a liquid? Clear? Good for the roof.? How is it applied?

- Why you would be coating a flat roof with Aluminum coating is beyond anything I have learned. Flat roofs should have a felt and tar coating to water proof them. Aluminum roof coating is used mostly on mobile homes to reflect heat because mobile homes don't have attics to trap the heat and carry it to vents. It also seals the water out at the metal seams. Aluminum coating is a type of polymer that has aluminum flakes in it. It is brushed on like a thick coat of paint and allowed to dry.

Send your message to us

1070 Aluminum Coil for Sale - Aluminium Coil Sheet in 1100, 3003, 5052, 5754

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords