030 Aluminum Coil 5754 5005,8079,8011,1050,1060

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Details: | Standard export packing or following customer's demand |

Delivery Detail: | Within 10-20days or according to the order quantity |

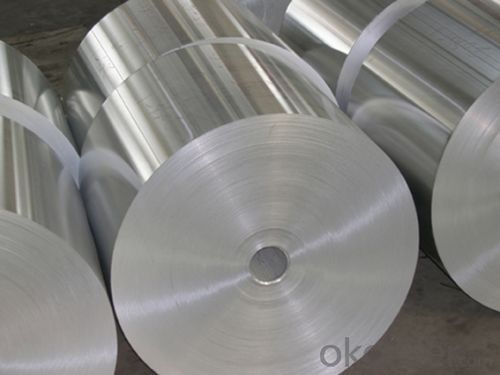

High Quality and Factory Price Aluminum Coil

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.05~10mm |

Width | <1600mm< span=""> |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~27micron(EN ISO-2360:1995) PVDF27 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

Payment | L/C ,T/T |

Parameter

Product | Alloy | Temper | Thickness | Width | I.D(mm) | Application |

Aluminum Coil/Strip | 1050,1060,1070, 1100,1200,1235, 1145,3003,304, 3105,3A21, 8011 | O H12 H14 H16 H18 H22 H24 H26 | 0.2-8mm | 50-2400mm | 75,150 200,300 400,505 (as customers's request) | construction,decoration, automobile,electronic, machinery,boat construction, aeronatics&astronautics, cookware,packing etc. |

Application:

1) Radiator

2) Condenser

3) Insulation Material

4) Construction

5) Decoration

6) Advertisement and market applications

Photos

- Q: Are aluminum coils resistant to abrasion?

- Aluminum coils are typically resistant to abrasion, thanks to their durability and ability to withstand wear and tear. Known for its high strength-to-weight ratio and exceptional corrosion resistance properties, aluminum is well-suited for applications that demand abrasion resistance. Moreover, protective finishes are commonly applied to aluminum coils, further bolstering their ability to resist abrasion. Nevertheless, the exact level of resistance can vary depending on the particular alloy and surface treatment used on the coils.

- Q: Is it possible to use aluminum coils as a material for crafting jewelry?

- <p>Yes, aluminum coils can be used to make jewelry. Aluminum is a lightweight, durable, and affordable metal that is often used in costume jewelry and art pieces. It's easy to work with, allowing for intricate designs and shapes. However, it's important to note that aluminum is not as valuable or as resistant to tarnishing as precious metals like gold or silver, so it may not be suitable for high-end or long-lasting jewelry pieces.</p>

- Q: Hi, I have a large bag of aluminium sulfate that I would like to use to turn my hydrangeas blue but there are no instructions on the pack, can anyone tell me how much I need (mixed with water)

- Si es tu profesora l. a. que te corrigio el blunders, sabe, quedate tranquila. El aluminio tiene número de oxidación +3 y el radical sulfato -2, intercambiando número de oxidación por atomicidad, para equilibrar, te queda lo que dijo tu profesora...

- Q: Can aluminum coils be used in automotive manufacturing?

- Automotive manufacturing can indeed utilize aluminum coils. Aluminum, a versatile and lightweight substance, presents several advantages within the automotive sector. Frequently employed for fabricating components such as body panels, engine blocks, wheels, and heat exchangers, aluminum's incorporation in automotive manufacturing enhances fuel efficiency by reducing vehicle weight and subsequently minimizing energy consumption. Furthermore, aluminum boasts exceptional resistance to corrosion, rendering it appropriate for deployment in diverse weather conditions. In conclusion, the extensive benefits associated with the utilization of aluminum coils in automotive manufacturing have led to its widespread adoption by numerous car manufacturers.

- Q: What are the maximum operating temperatures for aluminum coils?

- The maximum operating temperatures for aluminum coils typically range from 300 to 400 degrees Fahrenheit, depending on the specific grade and alloy of aluminum being used.

- Q: Can aluminum coils be used in the production of chemical storage tanks?

- Yes, aluminum coils can be used in the production of chemical storage tanks. Aluminum is a durable and corrosion-resistant material, making it suitable for containing various chemicals. Additionally, its lightweight nature allows for easier handling and installation of the storage tanks.

- Q: What are the common sizes of aluminum coils available?

- The common sizes of aluminum coils available vary depending on the specific application and industry. However, some standard sizes include widths ranging from 36 inches (91 cm) to 72 inches (183 cm) and thicknesses between 0.019 inches (0.048 cm) to 0.125 inches (0.318 cm). These sizes are commonly used in industries such as construction, automotive, and manufacturing.

- Q: Can aluminum coils be used in heat sinks?

- Yes, aluminum coils can be used in heat sinks. Aluminum is a popular choice for heat sinks due to its excellent thermal conductivity. Heat sinks are designed to dissipate heat from electronic components and other devices to prevent overheating. The use of aluminum coils in heat sinks allows for increased surface area, which enhances heat dissipation. The coils can be shaped and arranged in various configurations to optimize cooling efficiency. Additionally, aluminum is lightweight, corrosion-resistant, and cost-effective, making it a practical choice for heat sink applications.

- Q: Can a rolling machine be utilized to transform aluminum coils into flat sheets?

- <p>Yes, you can use a rolling machine to roll aluminum coils into sheets. Rolling machines are specifically designed to apply pressure and reduce the thickness of metal coils, such as aluminum, into thinner, flatter sheets. The process involves passing the aluminum coil through the rolling mill, where it is compressed between rollers. This process can be repeated to achieve the desired thickness and flatness of the aluminum sheet. It's important to ensure the rolling machine is suitable for aluminum and that the appropriate settings are used to avoid damaging the material or the machine.</p>

- Q: Are aluminum coils suitable for curtain wall systems?

- Yes, aluminum coils are highly suitable for curtain wall systems. Aluminum is a lightweight and durable material that offers numerous benefits for curtain wall applications. Firstly, aluminum coils are corrosion-resistant, ensuring the longevity and durability of the curtain wall system. This makes them ideal for exterior applications where the system is exposed to various weather conditions. Additionally, aluminum does not rust, which is a significant advantage over other materials like steel. Furthermore, aluminum coils can be easily extruded into various shapes and sizes, allowing for flexibility and creativity in curtain wall design. This enables architects and designers to create visually appealing and unique structures. Moreover, aluminum is a highly sustainable material. It is 100% recyclable, which means that it can be reused without any loss in quality. This makes aluminum coils an eco-friendly choice for curtain wall systems, aligning with the growing demand for sustainable building materials. Additionally, aluminum is a good conductor of heat and electricity, which can contribute to energy efficiency in curtain wall systems. By using thermal breaks and incorporating insulation, aluminum curtain walls can effectively regulate temperature and reduce energy consumption, leading to cost savings in the long run. Overall, aluminum coils are an excellent choice for curtain wall systems due to their corrosion resistance, versatility, sustainability, and energy efficiency.

Send your message to us

030 Aluminum Coil 5754 5005,8079,8011,1050,1060

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords