1060 Aluminum Coils Wholesale - Aluminum Coil 5754 8011 1050 1060 for Cans

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

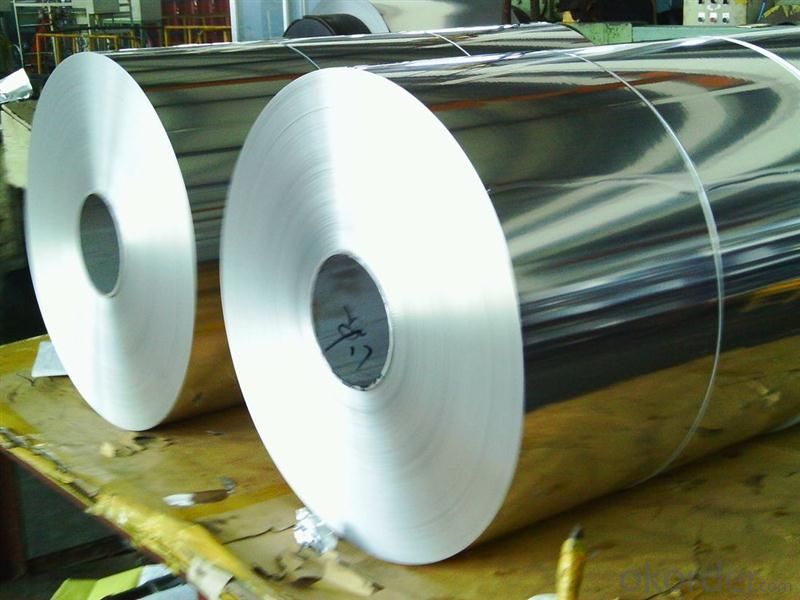

Aluminum Coil 5754 8011 1050 1060 Aluminum Coil For Cans

Applications:

Aluminum foil roll is widely used in construction,decoration,hardware,

electric appliances,machinery and other industrial and civil purposes,

such as electronic capacitor,composite cooker,rice cooker,refrigerator,

computer casting,telecommunication,equipment,lamp shade,air conditioner,

cosmetics cover and so on.

Or it can be made as customers’ requirement.

Specifications

color aluminum coil

1000 series 1100 10160 1200

surface could be: Brushed, drawing, embossed, printing

color: red,

color aluminum coil

.Alloy type: 1050/1060/1100/1350

2.Temper: H16, H18, H22, H24

3.Thickness range: 0.1mm-4mm

4.Width range: 25mm-1600mm

5.Surface:finish: bright & smooth surface, without flow lines, slight oiled to avoid white rusting.

6.Quality material:totally free from such defefects as roll marks, edge damager, camber, white rust, oil patches, holes, break lines,

color aluminum coil

Name |

color aluminum coil |

Alloy or not | yes |

Alloy | 1100H16/18, 3003H24,3003H26,3005H26,8011,3004,3105,5005,etc. |

Thickness | 0.1-4mm |

Width | ≤1600mm |

MOQ | 5T |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

- Q: This question asks for criteria or methods to determine if an aluminum coil is of high quality.

- <p>To identify a high-quality aluminum coil, consider the following factors: purity level, which should be 99.5% or higher for most applications; surface finish, ensuring it's smooth and free from defects; thickness consistency, which should be uniform across the entire coil; mechanical properties, such as tensile strength and elongation, that meet industry standards; and adherence to specific alloy grades for particular applications. Additionally, check for certifications from recognized standards organizations and consider the supplier's reputation for quality and consistency.</p>

- Q: Can aluminum coils be used in the production of automotive body panels?

- Yes, aluminum coils can be used in the production of automotive body panels. Aluminum is a lightweight and durable material that offers excellent corrosion resistance, making it ideal for automotive applications. The use of aluminum coils helps to reduce the weight of the vehicle, resulting in improved fuel efficiency and overall performance.

- Q: What causes tower after cutting aluminum coil

- Insulation aluminum coil will appear when the cooling bending phenomenon, reason is generally under the conditions of air cooling, the heat transfer coefficient of the aluminum coil insulation parts in contact with the air were flat, but because the wall thickness or different shapes, different parts of the heat dissipation rate is not balanced, resulting in thick wall or hollow tube heat faster than the thin Department of slow, resulting in insulating aluminum roll cooling occurs to the hollow part.

- Q: Can aluminum coils be used for pharmaceutical packaging?

- Yes, aluminum coils can be used for pharmaceutical packaging. Aluminum is a popular choice for pharmaceutical packaging due to its various beneficial properties. It is lightweight, corrosion-resistant, and has excellent barrier properties, making it ideal for protecting pharmaceutical products from external factors such as moisture, oxygen, and light. Aluminum coils can be easily formed into different shapes and sizes, providing versatility for packaging needs. Additionally, aluminum is non-toxic and non-reactive, ensuring the safety and integrity of pharmaceutical products.

- Q: What is the role of aluminum coils in the construction of ships?

- The marine industry heavily relies on aluminum coils for the construction of ships. These coils are essential in manufacturing various ship components and structures. The lightweight nature of aluminum coils is a significant advantage in ship construction. Compared to traditional steel, aluminum is much lighter, resulting in improved fuel efficiency and overall performance of the ship. This is particularly beneficial for larger vessels, as reducing weight helps minimize energy consumption and operating costs. Furthermore, aluminum coils offer outstanding resistance to corrosion, making them ideal for the harsh marine environment. Ships constantly face exposure to corrosive saltwater, which can deteriorate metal materials. By utilizing aluminum coils, shipbuilders can ensure that their vessels are well-protected against rust and corrosion, ultimately extending their lifespan and reducing maintenance needs. Additionally, aluminum coils are easily shaped and formed into various structures, providing shipbuilders with greater design flexibility. This versatility allows for the creation of intricate ship components like hulls, superstructures, and bulkheads. Aluminum's excellent weldability also simplifies the process of joining different sections of the ship, resulting in more efficient and streamlined construction. Moreover, aluminum is a highly sustainable material. It can be recycled without any loss in quality or performance, making aluminum coils an environmentally friendly choice for ship construction. This aligns with the increasing focus on sustainability in the industry. In conclusion, aluminum coils play a multifaceted role in ship construction. They offer lightweight, corrosion-resistant, and easily formable materials that contribute to improved fuel efficiency, durability, and design flexibility. Additionally, their recyclability makes them an environmentally conscious option. Overall, aluminum coils are a vital component in building efficient, durable, and sustainable ships.

- Q: The user is asking if it's possible to use a punching machine to create holes in aluminum coils.

- <p>Yes, you can use a punching machine to punch holes in aluminum coils. Punching machines are designed to cut or create holes in various materials, including metals like aluminum. However, the type of punching machine and the specific settings will depend on the thickness and hardness of the aluminum coils. For thicker or harder aluminum, a more robust machine with appropriate dies may be necessary. Ensure that the machine is capable of handling the material's properties to avoid damage or inefficiencies in the punching process.</p>

- Q: Is it possible to construct a portable speaker or speaker docking station using aluminum coils?

- <p>Yes, you can use aluminum coils in the construction of a portable speaker or speaker docking station, but they are not the primary component. Aluminum coils can be used in the speaker's electromagnetic parts, such as in the voice coil of the speaker driver or in the transformer of a docking station. However, the main components of a speaker include a diaphragm, voice coil, magnet, and enclosure, while a docking station would require a connector for the device, an amplifier, and possibly additional circuitry. The aluminum coil's role is to facilitate the magnetic field interaction with the voice coil, which converts electrical signals into sound waves. It's essential to consider the entire design and other necessary components when building such devices.</p>

- Q: Are there any specific certifications or qualifications required for aluminum coil suppliers?

- Certifications and qualifications that are essential for aluminum coil suppliers do exist. The ISO 9001 certification is a vital one for these suppliers as it guarantees the implementation of a quality management system and adherence to international quality standards. When a supplier possesses this certification, it demonstrates their effective quality control processes, consistent product performance, and ability to satisfy customers. Another critical qualification for aluminum coil suppliers is the AS9100 certification, particularly for those serving the aerospace industry. This certification verifies that the supplier has fulfilled the industry-specific requirements for quality management systems, including rigorous quality control, traceability, and compliance with industry standards. Moreover, aluminum coil suppliers may also need to conform to industry-specific standards like the ASTM standards or the REACH regulations of the European Union concerning chemical substances. These standards ensure that the supplier's products fulfill the necessary specifications and are safe to use in various applications. Furthermore, certain aluminum coil suppliers may possess specialized certifications or qualifications tailored to specific industries or applications. For instance, suppliers serving the automotive industry may hold certifications like the IATF 16949 certification, which demonstrates their ability to meet the demanding requirements of automotive manufacturers. In conclusion, while the specific certifications and qualifications required may vary depending on the industry and application, it is crucial for aluminum coil suppliers to possess certifications like ISO 9001 and industry-specific certifications to ensure their products meet the required quality standards and comply with relevant regulations.

- Q: Can aluminum coils be used in kitchen appliances?

- Yes, aluminum coils can be used in kitchen appliances. They are commonly used in refrigerators, air conditioners, and other appliances due to their excellent thermal conductivity and corrosion resistance properties.

- Q: What are the potential dangers associated with the use of aluminum coil?

- <p>Aluminum coil, when used in appropriate applications and handled correctly, is generally safe. However, there are some safety risks to consider: exposure to aluminum dust can cause respiratory issues, and improper handling can lead to cuts or burns. Additionally, aluminum can react with certain chemicals, potentially causing hazardous situations. It's important to use personal protective equipment and follow safety guidelines when working with aluminum coil to minimize these risks.</p>

Send your message to us

1060 Aluminum Coils Wholesale - Aluminum Coil 5754 8011 1050 1060 for Cans

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords