Large Sheets of Aluminum Checkered Aluminium Sheet 5005 Alloy for Automotive

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Checkered Aluminium Sheet 5005 Alloy for Automotive

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Checkered Aluminium Sheet 5005 Alloy for Automotive

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Checkered Aluminium Sheet 5005 Alloy for Automotive

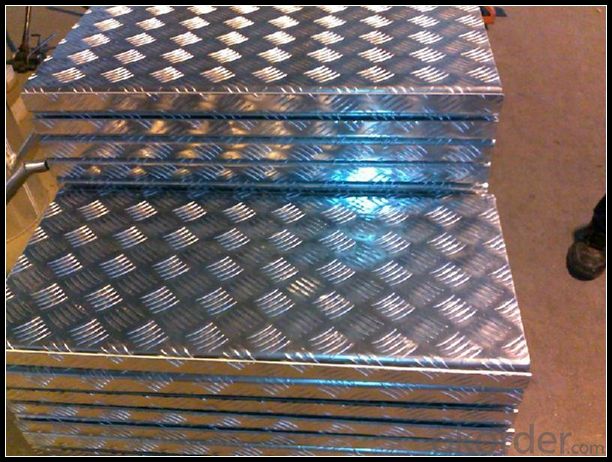

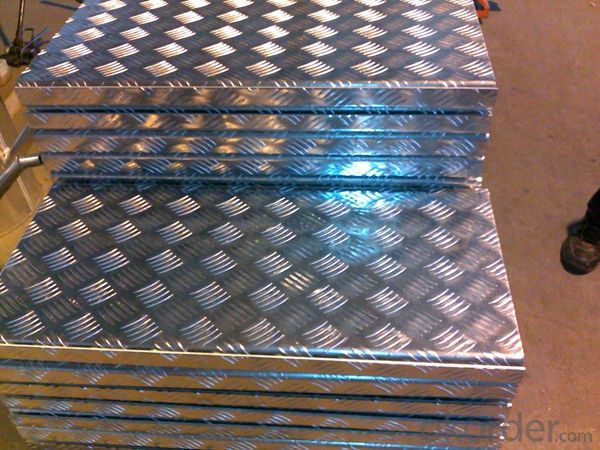

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

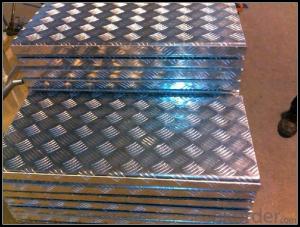

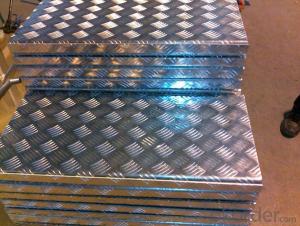

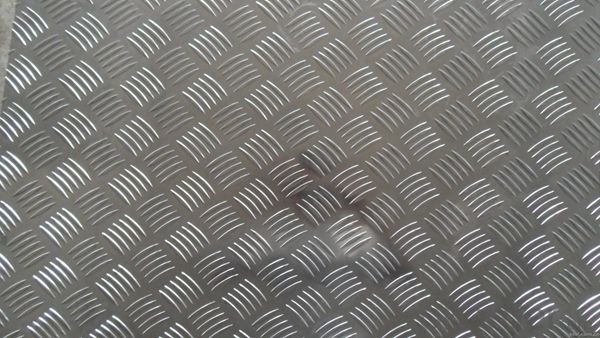

5. Image of Checkered Aluminium Sheet 5005 Alloy for Automotive

6. Package and shipping of Checkered Aluminium Sheet 5005 Alloy for Automotive

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks about the impact of aluminum sheets on the quality of air inside a building.

- <p>Aluminum sheets themselves do not directly affect indoor air quality in a building. They are inert materials that do not emit harmful gases or particles. However, the installation process may involve adhesives or sealants that could release volatile organic compounds (VOCs) temporarily, which can affect air quality. Proper ventilation during installation and after can mitigate this. Additionally, aluminum sheets can contribute to better air quality by providing a barrier against moisture and mold growth, which can be a concern with other building materials.</p>

- Q: What are the various types of insulation materials that can be combined with aluminum sheets for thermal or acoustic insulation purposes?

- <p>There are several types of insulation that can be used in conjunction with aluminum sheets, including: 1. Polyurethane foam, which provides excellent thermal insulation and can be bonded to aluminum sheets. 2. Mineral wool, a fire-resistant material that offers both thermal and acoustic insulation. 3. Polyisocyanurate, known for its high R-value and can be laminated to aluminum for added strength. 4. Extruded polystyrene, which is lightweight and provides good thermal resistance. 5. Fiberglass, a versatile insulation material that can be combined with aluminum for various applications. Each type has its specific properties and applications, making them suitable for different environments and insulation needs.</p>

- Q: How do aluminum sheets compare to other metals?

- When comparing aluminum sheets to other metals, several advantages can be identified. Firstly, aluminum is known for its lightweight properties, making it an excellent option for industries that prioritize weight, such as aerospace. Moreover, aluminum exhibits exceptional resistance to corrosion, allowing it to endure exposure to moisture and chemicals without deterioration. As a result, aluminum sheets are suitable for outdoor use and in environments with high humidity or corrosive substances. Additionally, aluminum possesses excellent thermal and electrical conductivity, making it a popular choice for applications that require efficient heat dissipation or electrical conduction, including heat sinks and electrical enclosures. Furthermore, aluminum sheets can be easily manipulated and formed, providing versatility in various manufacturing processes. They can be effortlessly bent, cut, welded, and machined, making them highly adaptable to different design specifications. When considering cost, aluminum generally proves to be more affordable compared to other metals like steel or copper. This affordability makes it a cost-effective option for numerous industries, particularly for large-scale production or projects with budget constraints. However, it is vital to note that aluminum sheets may not be suitable for applications that demand high strength or extreme temperatures, as aluminum has lower strength and melting points in comparison to certain other metals. In such cases, metals such as steel or titanium may be more appropriate. In conclusion, aluminum sheets possess a combination of qualities, including lightweight properties, corrosion resistance, good conductivity, versatility, and affordability, which make them a preferred choice in many industries. Nevertheless, it is crucial to consider the specific requirements of a project or application to determine if aluminum sheets are the most suitable option or if another metal would be more appropriate.

- Q: Are 101 aluminum sheets suitable for chemical processing environments?

- No, 101 aluminum sheets are not suitable for chemical processing environments as they are not corrosion-resistant and may react with certain chemicals, leading to potential damage or contamination.

- Q: has aluminum sheet reacted with concentrated sulfuric acid?

- it can be regarded as no reaction, concentrated sulfuric acid will make aluminum's surface inactivation,and produce a layer of dense aluminium oxide film which will prevent further reaction.

- Q: Can aluminum sheet be used for aircraft skin panels?

- Certainly, aircraft skin panels can indeed be made from aluminum sheet. As a matter of fact, aluminum is extensively employed as the preferred material for constructing such panels owing to its highly advantageous properties. Aluminum possesses the qualities of being lightweight, robust, and resistant to corrosion, rendering it an ideal selection for aircraft production. Moreover, aluminum is effortlessly malleable, facilitating the shaping of the panels into the precise contours and curves necessary for aircraft design. Furthermore, it exhibits commendable heat conductivity, aiding in the dissipation of heat generated during flight. All in all, aluminum sheet is an exceptionally reliable and efficient material for the fabrication of aircraft skin panels.

- Q: What is the standard size of an aluminum sheet?

- Depending on the specific application and industry, the standard size of an aluminum sheet may vary. However, typically, aluminum sheets come in commonly found standard sizes such as 4 feet by 8 feet or 48 inches by 96 inches. These dimensions are extensively used in various industries like construction and manufacturing due to their adaptability and compatibility with standard equipment and processes. Nevertheless, it is crucial to acknowledge that aluminum sheets can also be personalized by cutting or ordering them in different sizes to fulfill specific project necessities.

- Q: What is the thickness range available for 101 aluminum sheets?

- The thickness of 101 aluminum sheets can differ depending on the manufacturer and supplier. Typically, these sheets come in various thicknesses, ranging from 0.016 inches (0.41 mm) to 0.25 inches (6.35 mm). It is crucial to mention that this range does not encompass all possibilities, as there might be alternative thickness options or customizable choices depending on specific needs or preferences.

- Q: Are aluminum sheets suitable for medical applications?

- Yes, aluminum sheets are suitable for medical applications. Aluminum is a lightweight and durable material that is resistant to corrosion, making it suitable for medical equipment and devices. It is commonly used in the production of medical instruments, diagnostic imaging systems, and surgical trays. Additionally, aluminum sheets can be sterilized easily, further enhancing their suitability for medical applications.

- Q: What is the color range available for aluminum sheets?

- The color range available for aluminum sheets is quite diverse and extensive. Aluminum sheets can be found in a variety of standard colors, including but not limited to silver, black, white, bronze, and gold. Additionally, aluminum sheets can be coated with various finishes, such as anodized, painted, or powder coated, which can further expand the color options. These coatings can provide a wide range of colors, including vibrant shades like red, blue, green, yellow, and more. Furthermore, custom colors can also be achieved through specialized processes, allowing for personalized and unique color choices. Overall, the color range available for aluminum sheets is extensive and flexible, catering to various aesthetic preferences and design requirements.

Send your message to us

Large Sheets of Aluminum Checkered Aluminium Sheet 5005 Alloy for Automotive

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords