China Brushed Aluminum Sheets - Checkered Aluminium Plate 5005 Alloy for Automotive

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Checkered Aluminium Plate 5005 Alloy for Automotive

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Checkered Aluminium Plate 5005 Alloy for Automotive

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Checkered Aluminium Plate 5005 Alloy for Automotive

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

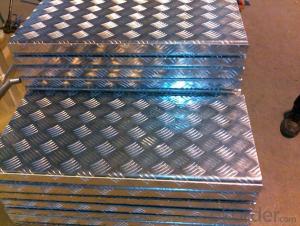

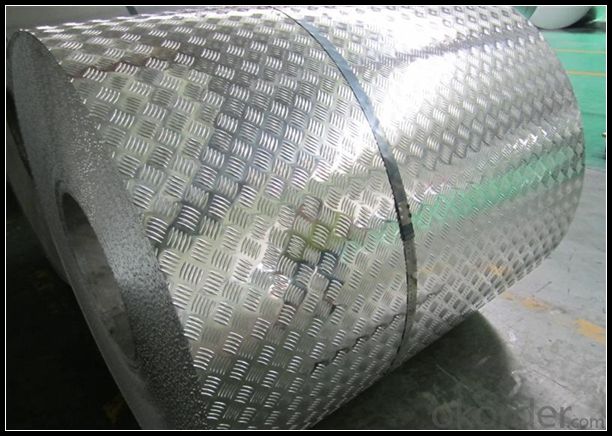

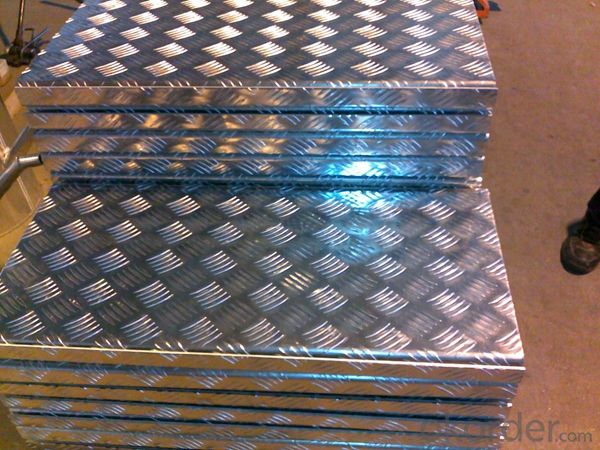

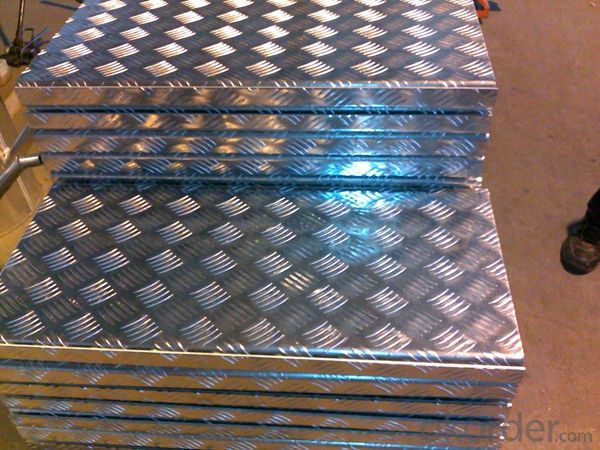

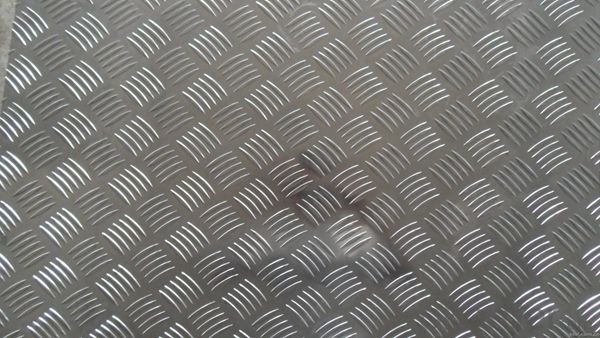

5. Image of Checkered Aluminium Plate 5005 Alloy for Automotive

6. Package and shipping of Checkered Aluminium Plate 5005 Alloy for Automotive

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Where is the difference between the 5052 aluminum plate and the 1060 Aluminum plate?

- 5052 is aluminium magnesium alloy, 1060 is pure aluminium

- Q: Can aluminum sheets be used for solar reflectors?

- Indeed, solar reflectors can utilize aluminum sheets. With its high reflectivity and exceptional resistance to heat, aluminum emerges as an optimal material for such purposes. The reflectiveness of aluminum sheets aids in redirecting and intensifying sunlight onto solar panels or other solar equipment, thereby maximizing their energy efficiency. Moreover, the lightweight and durable nature of aluminum renders it effortlessly manageable and fitting for outdoor applications.

- Q: Can aluminum sheet be used for signage?

- Yes, aluminum sheet can be used for signage due to its durability, lightweight nature, and resistance to corrosion, making it a popular choice for a wide range of indoor and outdoor signage applications.

- Q: Can aluminum sheets be used for HVAC systems?

- Certainly, HVAC systems can utilize aluminum sheets. Aluminum proves to be a favored material for HVAC applications owing to its numerous beneficial characteristics. Its lightweight nature facilitates effortless handling and installation. Moreover, aluminum exhibits remarkable resistance to corrosion, a vital attribute for HVAC systems subject to moisture and fluctuating temperatures. Additionally, aluminum boasts exceptional thermal conductivity, ensuring efficient heat transfer. Consequently, it becomes ideal for heat exchangers and other HVAC system components. In summary, aluminum sheets emerge as a dependable and long-lasting choice for HVAC systems.

- Q: Are aluminum sheets suitable for transportation applications?

- Yes, aluminum sheets are suitable for transportation applications. Aluminum is a lightweight and strong material, making it ideal for various transportation purposes. It is commonly used in the aerospace industry for constructing aircraft structures, as well as in the automotive industry for manufacturing vehicle bodies, frames, and components. The use of aluminum sheets in transportation applications helps to reduce the overall weight of vehicles, which can improve fuel efficiency and increase payload capacity. Additionally, aluminum is resistant to corrosion, making it durable and long-lasting, even in harsh environments. Overall, the properties of aluminum sheets make them a suitable choice for transportation applications.

- Q: What kind of material is 2A12 aluminum sheet?

- The temperature is higher than 125 degrees C, and the strength of the 2024 alloy is higher than that of the 7075 alloy. Under the condition of hot state, annealing and new quenching, the formability is better, and the strengthening effect of heat treatment is remarkable, but the heat treatment process is strict.

- Q: What is the fire rating of 101 aluminum sheets?

- The fire rating of 101 aluminum sheets is typically dependent on the particular alloy and thickness of the sheets. Due to its low melting point of 660 degrees Celsius (1220 degrees Fahrenheit), aluminum has the potential to deform or melt when exposed to intense heat. Nevertheless, it is important to highlight that aluminum is not flammable and does not aid in the propagation of fire. Fire resistance can be improved by applying fire-resistant coatings or by incorporating it with other fire-resistant substances. In conclusion, it is crucial to seek advice from manufacturers or industry professionals to ascertain the fire rating of specific 101 aluminum sheets.

- Q: What is the atomic mass of aluminum?

- The atomic mass of aluminum is approximately 26.98 atomic mass units.

- Q: An aluminum clock pendulum having a period of 1.00 s keeps perfect time at 20 degrees celcius. (A) When placed in a room at a temperature of -5.0 Celcius, will it gain or lose time? (B)How much time will it gain or lose every hour.

- this concerns change in length of aluminum due to fall in temp T(20 C) = 2pi√(L20/g = 1 sec L20 = g/4pi^2 ----------- (1) T(-5 C) = 2pi√(L5/g L5 = T(5)^2*g /4pi^2 ----------- (2) coefficient of linear expansion of aluminum = alpha alpha = delta L/L* delta T 23*10^-6 = (L5 - L20) /L20*(- 5 - 20) (L5 - L20) /L20 = - 25*23*10^-6 L5/L20 = 1 - 25*23*10^-6 = 0.999425 --- (3) L5 decrease in length T(5) will reduce (2) / (1) L5/L20 = [T(5)^2*g /4pi^2] * [4pi^2/g] = 0.999425 [T(5)^2] = 0.999425 T(5) = 0.9997 sec this is period when in (-5 C) room a) pendulum gains time in cold room word gains is used because it takes less in 1 oscillation. b) it gains time = 1 - 0.9997 = 0.0003 sec in 1 sec gain in every hour = 0.0003*3600 = 1.08 sec

- Q: Are aluminum sheets suitable for use in cryogenic environments?

- Yes, aluminum sheets are suitable for use in cryogenic environments. Aluminum has excellent thermal conductivity and low density, making it an ideal material for cryogenic applications. It can withstand extremely low temperatures without losing its structural integrity or experiencing significant thermal expansion. Additionally, aluminum has good corrosion resistance and can be easily fabricated into various shapes and sizes. These properties make aluminum sheets commonly used in cryogenic systems, such as cryostats, superconducting magnets, and liquid nitrogen storage tanks.

Send your message to us

China Brushed Aluminum Sheets - Checkered Aluminium Plate 5005 Alloy for Automotive

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords