Flat Aluminum Sheets - Mill Finished Checkered Aluminium Plate 5005 Alloy for Automotive

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finished Checkered Aluminium Plate 5005 Alloy for Automotive

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Mill Finished Checkered Aluminium Plate 5005 Alloy for Automotive

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finished Checkered Aluminium Plate 5005 Alloy for Automotive

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

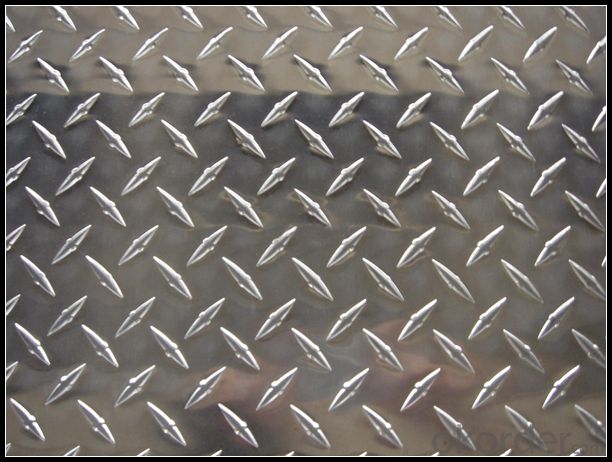

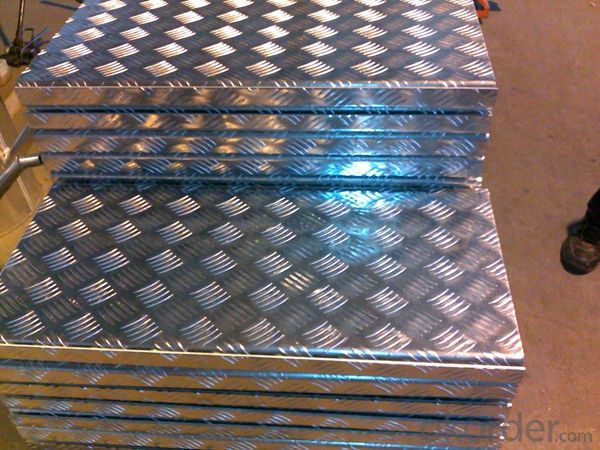

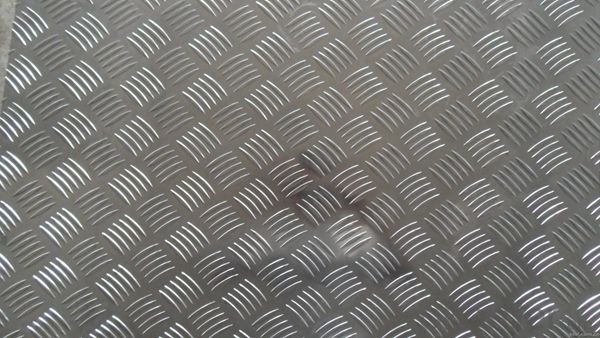

5. Image of Mill Finished Checkered Aluminium Plate 5005 Alloy for Automotive

6. Package and shipping of Mill Finished Checkered Aluminium Plate 5005 Alloy for Automotive

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question is asking for a list of different types of fasteners that can be used to attach aluminum sheets to a structure.

- <p>There are several types of fasteners used for attaching aluminum sheets to a structure, including: 1. Rivets: These are permanent fasteners that join two pieces by deforming the rivet material. 2. Screws: These are threaded fasteners that can be inserted and removed as needed. 3. Bolts: Similar to screws, bolts are used with nuts to secure aluminum sheets. 4. Adhesives: Chemical adhesives can be used for bonding aluminum sheets without visible fasteners. 5. Welding: Although not a fastener, welding can join aluminum sheets permanently. 6. Clips and Clamps: These are used for temporary or non-structural attachment. 7. Self-tapping screws: These screws create their own threads in the material being fastened. Each type has its own advantages and is chosen based on the specific requirements of the project.</p>

- Q: Are aluminum sheets suitable for electrical enclosures?

- Yes, aluminum sheets are suitable for electrical enclosures. Aluminum is a lightweight and durable material that offers excellent conductivity and corrosion resistance. It also has good heat dissipation properties, making it ideal for enclosures that house electrical components. Moreover, aluminum is easy to fabricate and can be formed into various shapes and sizes, allowing for customization of the enclosure design. Additionally, aluminum sheets can be coated or anodized to enhance their resistance to environmental factors like moisture, dust, and chemicals. Overall, aluminum sheets provide a reliable option for electrical enclosures due to their electrical and mechanical properties, as well as their ability to protect sensitive electrical equipment.

- Q: Can aluminum sheet be used for signage?

- Yes, aluminum sheet can be used for signage. Aluminum is a popular choice for signage due to its durability, versatility, and cost-effectiveness. It is a lightweight material that is resistant to corrosion, making it suitable for both indoor and outdoor signage. Aluminum sheet can be easily cut, shaped, and formed into various sizes and designs, allowing for customizable signage options. Additionally, aluminum can be easily printed or engraved upon, making it ideal for displaying text, graphics, and logos. Its sleek and professional appearance adds to its appeal for signage purposes. Overall, aluminum sheet is an excellent choice for signage due to its durability, versatility, and aesthetic qualities.

- Q: What are the semi hard ones? What are the alloys? What are the anti rust ones, such as 3003505210606061, 7075?

- 3003: board. Strip foil. Tensile plate, tube. Extrusion tube. Type. Rod. Rod. Cold bar, cold wire, rivet wire, forging, foil, heat sink material mainly used for processing requires good molding property, high corrosion resistance, good weldability and spare parts not only have these requirements, or performance need than the workpiece of 1*** alloy with high strength, such as transportation of liquid tank and tank, pressure tank, storage device, heat exchanger, chemical equipment, aircraft fuel tank, oil pipe, reflective panels, kitchen equipment, cylinder washing machine, rivet, welding wire.3003 aluminum alloy sheet, plate, tube drawing. The extruded tube housing partition, cap, pipe3004 plate, plate, pipe extrusion tube for tensile. As long as the whole aluminum cans cans, for more than 3003 alloy parts, chemical products production and storage device, sheet processing, building baffle, cable conduit, sewer, various lighting components.3004 aluminum alloy sheet, plate mainly used for housing partition, baffle, sewer, the roof of industrial plant5052 plate, plate, sheet, foil, drawing tube, cold processing bar, cold wire, rivet wire, this alloy has good shaping property, high corrosion resistance, weldability and fatigue strength, medium static strength, used in the manufacture of aircraft fuel tank, tubing, and vehicles, sheet metal parts, ship the instrument, street lamp and rivet wire and so on.

- Q: How to polish aluminum sheet to be bright?

- you can try mirror polishing agent.

- Q: Can aluminum sheets be used for food packaging?

- Yes, aluminum sheets can be used for food packaging. Aluminum is a safe and widely used material in the food industry due to its excellent barrier properties, resistance to moisture, and ability to maintain product freshness.

- Q: Is it possible to use adhesive instead of fasteners to bond aluminum sheets to a structure?

- <p>Yes, you can use an adhesive to attach aluminum sheets to a structure. However, it's important to choose an adhesive that is specifically designed for bonding aluminum, as not all adhesives provide the necessary strength and durability. Structural adhesives that are compatible with aluminum can offer a strong bond and are often used in applications where a clean, seamless appearance is desired or where fasteners are not suitable. It's crucial to ensure that the adhesive is resistant to the environmental conditions the structure will be exposed to, such as moisture, temperature fluctuations, and UV radiation. Always follow the manufacturer's instructions for surface preparation and application to achieve the best results.</p>

- Q: Can aluminum sheets be used in aerospace industry?

- Aluminum sheets find common usage within the aerospace industry due to their numerous desirable qualities. One of the foremost advantages is their lightweight nature, a critical factor for both aircraft and spacecraft. This characteristic aids in reducing fuel consumption and increasing the capacity for payload. Another significant attribute of aluminum is its exceptional strength-to-weight ratio, which imparts structural integrity to aerospace components. Furthermore, aluminum exhibits high resistance to corrosion, ensuring longevity and durability within harsh environments. Additionally, its commendable thermal conductivity qualifies it for heat dissipation in aerospace systems. Moreover, aluminum boasts easy formability, enabling the manufacturing of intricate shapes and structures. In summary, the versatility, strength, lightness, and corrosion resistance of aluminum make it the material of choice in the aerospace industry for diverse applications, including aircraft frames, fuselage panels, wings, and engine components.

- Q: This question asks if aluminum sheets are suitable for outdoor use in environments with high temperatures.

- <p>Yes, aluminum sheets can be used for outdoor applications even in high temperatures. Aluminum has a high melting point of around 660掳C (1220掳F), making it resistant to heat. It also has good thermal conductivity, which allows it to dissipate heat quickly. However, it's important to note that prolonged exposure to high temperatures can cause aluminum to expand and potentially warp. For outdoor applications, especially in high-temperature environments, it's recommended to use aluminum alloys designed for such conditions to ensure durability and performance.</p>

- Q: Explain how the use of aluminum sheets can impact the visual appeal of a building.

- <p>Aluminum sheets can significantly enhance the aesthetic appearance of a building due to their versatility, durability, and modern look. They offer a sleek and contemporary design, available in various colors, finishes, and textures, allowing architects to create unique and visually striking facades. Their resistance to corrosion and weathering ensures that the building maintains its appearance over time, while their lightweight nature can contribute to innovative architectural designs. Additionally, aluminum sheets can be easily shaped and cut, enabling complex and intricate designs that add to the visual appeal of the structure.</p>

Send your message to us

Flat Aluminum Sheets - Mill Finished Checkered Aluminium Plate 5005 Alloy for Automotive

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords