Aluminum Square Sheets Checkered Aluminium Sheets AA5005 for Making Aluminium Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Checkered Aluminium Sheets AA5005 for Making Aluminium Trailers

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Checkered Aluminium Sheets AA5005 for Making Aluminium Trailers

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Checkered Aluminium Sheets AA5005 for Making Aluminium Trailers

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

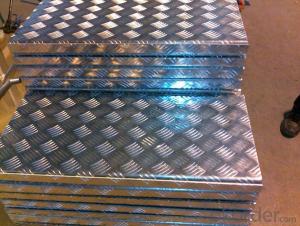

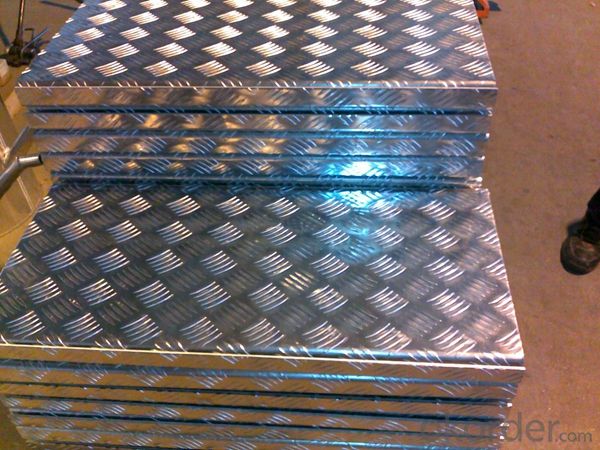

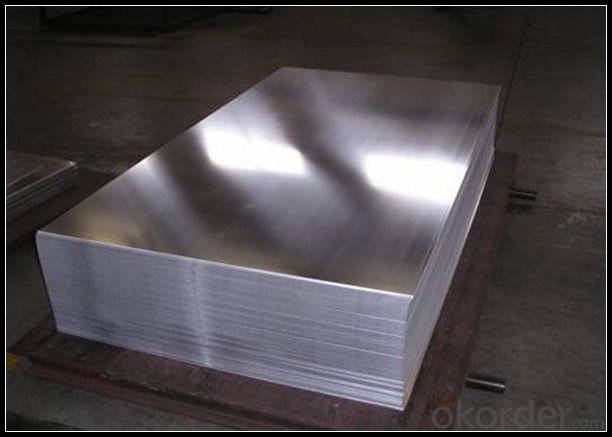

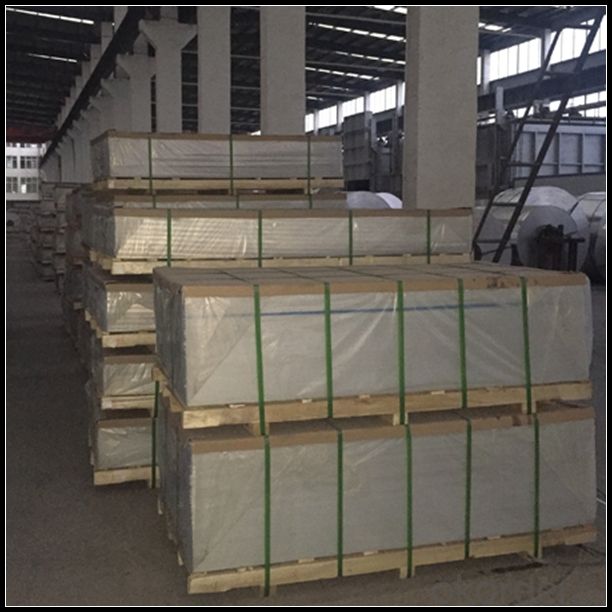

5. Image of Checkered Aluminium Sheets AA5005 for Making Aluminium Trailers

6. Package and shipping of Checkered Aluminium Sheets AA5005 for Making Aluminium Trailers

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: aluminum is used to make planes, cast iron is used to make heavy mashines. what is the comparisonof teh densities of aluminum and cast iron?

- The density of aluminum is MUCH lower than cast iron (thus, aluminum is LIGHTER). Because it is lighter, it would be much more ideal for applications like plane building, which is why aluminum is used over cast iron in airplanes. As well, aluminum has a protective coating called aluminum oxide which protects it from corroding in water. [Answer: see above]

- Q: Are aluminum sheets suitable for automotive applications?

- Yes, aluminum sheets are suitable for automotive applications. They are lightweight, corrosion-resistant, and offer excellent strength-to-weight ratio, making them ideal for various components in vehicles such as body panels, hoods, doors, and engine parts.

- Q: Is it possible to use aluminum sheets as a material for interior wall decoration?

- <p>Yes, aluminum sheets can be used for interior wall cladding. They are lightweight, durable, and resistant to corrosion, making them suitable for various interior applications. Aluminum sheets are also easy to install and maintain, and they can be painted or finished in various ways to match different design styles. However, it's important to ensure proper installation and adherence to local building codes and regulations.</p>

- Q: Can 101 aluminum sheets be used in the production of nameplates or tags?

- Yes, 101 aluminum sheets can be used in the production of nameplates or tags. Aluminum is a popular material choice for nameplates and tags due to its durability, lightweight nature, and resistance to corrosion. The 101 aluminum alloy, which is a commercially pure aluminum, offers excellent formability and workability, making it suitable for various manufacturing processes such as stamping, engraving, or etching. It can be easily cut, shaped, and customized to create high-quality nameplates or tags with clear and precise markings. Additionally, aluminum's ability to withstand harsh environments and its attractive appearance make it a preferred choice for many industries, including automotive, aerospace, electronics, and signage. Therefore, 101 aluminum sheets are a suitable material for the production of nameplates or tags.

- Q: Can aluminum sheets be used for solar panel frames?

- Yes, aluminum sheets can be used for solar panel frames. Aluminum is a popular choice for solar panel frames due to its lightweight, corrosion-resistant, and durable properties. It allows for easy installation, reduces overall weight, and provides structural support for the solar panels. Additionally, aluminum frames can withstand various weather conditions and ensure the longevity of the solar panel system.

- Q: Can aluminum sheets be used for cryogenic applications?

- Aluminum sheets are indeed applicable for cryogenic purposes. Their suitability arises from their commendable thermal conductivity and low density. These qualities enable them to endure exceedingly low temperatures without succumbing to brittleness or compromising their mechanical attributes. Furthermore, aluminum exhibits non-magnetic properties and exceptional resistance to corrosion, rendering it highly significant in cryogenic applications. Nevertheless, it is crucial to meticulously choose the appropriate alloy and thickness of the aluminum sheet, considering the precise cryogenic temperature and intended use, to guarantee optimal performance.

- Q: Some say you should use the 'dull' side of aluminum foil when cooking etc. There's something potentially bad about the shiny side.True or not?

- Straight from Reynolds: Which side of Reynolds Wrap? Aluminum Foil should I use, the shiny or the dull side? Actually, it makes no difference which side of the aluminum foil you use—both sides do the same fine job of cooking, freezing and storing food. The difference in appearance between dull and shiny is due to the foil manufacturing process. In the final rolling step, two layers of foil are passed through the rolling mill at the same time. The side coming in contact with the mill's highly polished steel rollers becomes shiny. The other side, not coming in contact with the heavy rollers, comes out with a dull or matte finish. The exception is when using Reynolds Wrap? Release? Non-Stick Aluminum Foil. The non-stick coating is applied during manufacturing to the dull side of the foil. Always place the non-stick (dull) side toward the food.

- Q: Characteristics of anodized aluminium plate

- (5) strong pollution resistance: no fingerprints, but also traces of dirt, easy to clean, no corrosion spots.(6) applicability: it is widely used in metal aluminum ceiling, curtain wall, aluminum plate, aluminum plastic panel, fireproof board, honeycomb aluminum plate, aluminum veneer, electrical panel, cabinet panel, furniture panel, etc..

- Q: Are aluminum sheets suitable for use in marine or saltwater environments?

- Aluminum sheets are indeed appropriate for utilization in marine or saltwater settings. Aluminum boasts exceptional resistance to corrosion and is renowned for its capacity to endure the challenging conditions present in marine environments. In contrast to numerous other metals, when aluminum is exposed to oxygen, it forms a shielding oxide layer on its surface, which aids in thwarting further corrosion. This oxide layer serves as a barrier, shielding the underlying metal from saltwater and other detrimental elements. Furthermore, aluminum is both lightweight and robust, rendering it an optimal selection for marine applications that prioritize weight reduction. It is commonly employed in the construction of boats, ships, offshore structures, and various other marine apparatus.

- Q: What is the typical lead time for ordering aluminum sheets?

- The lead time for ordering aluminum sheets can vary depending on factors such as the supplier, quantity of sheets ordered, and demand for aluminum. Generally, lead times can range from a few days to several weeks. If you are looking for standard-sized aluminum sheets that are readily available, the lead time is usually shorter, typically ranging from a few days to a week. Suppliers have these common sizes in stock and can ship them quickly. However, if you need custom-sized sheets or a large quantity that is not readily available, the lead time may be longer. In these cases, the supplier may need to source the aluminum, cut it to size, and process any necessary treatments or finishes. This process can take several weeks, especially if the supplier has a high volume of orders or if the aluminum needs to be imported. To determine the specific lead time for your order, it is important to communicate with the supplier. They can provide an estimated timeframe based on their production capacity, stock availability, and other factors that may affect the lead time.

Send your message to us

Aluminum Square Sheets Checkered Aluminium Sheets AA5005 for Making Aluminium Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords