Aluminum Alloy 5052 Sheets - Big Five Bars for Different Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

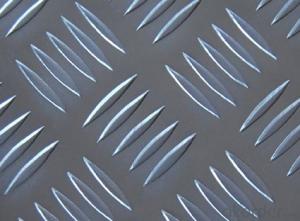

1.Structure of Big Five Bars Aluminum Sheets for Different Usages

Big five bars aluminum sheets are good at ductility, heat conductivity, anti-corrosion and moisture resistance.

They are widely used in decorative purchase in construction, packing and appliance. They are also very popularly used in anti-slippery purchase in vehicles and public places.

Our aluminum sheets can meet the highest standards its own mill while save the cost. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier. CNBM aluminum complying with YS/T 429-2000(Chinese Industry Standard),GB/T 3880,EN485,ASTM B209.

2.Main Features of Big Five Bars Aluminum Sheets for Different Usages

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

3. Big Five Bars Aluminum Sheets for Different Usages Images

4.Specification of Big Five Bars Aluminum Sheets for Different Usages

Alloy: AA1050, AA1060, AA1070, AA1100, AA3003, AA3004, AA3005, AA3105, AA5052

Temper: H14, H18, H24, H26, H32

Thickness: 0.2-20mm

Width:10mm- 1500mm

Embossed patterns: big five bars

Standard: GB/T3880-2006, ASTM, ISO, EU standard

5.FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Can aluminum sheets be used for window frames?

- Yes, aluminum sheets can be used for window frames. Aluminum is a popular choice for window frames due to its durability, lightweight nature, and resistance to corrosion. Aluminum frames offer excellent strength and stability, and they can be easily customized to fit any window size or shape. Additionally, aluminum frames require minimal maintenance and can be painted or anodized to match any desired color or finish. Overall, aluminum sheets are a versatile and reliable material for constructing window frames.

- Q: Can aluminum sheets be an alternative to plastic in certain applications?

- Indeed, aluminum sheets have the potential to serve as a viable substitute for plastic in specific scenarios. Aluminum, as a material, possesses the qualities of being lightweight and long-lasting, presenting numerous advantages over plastic. It boasts an outstanding strength-to-weight ratio, rendering it suitable for applications that demand resilience to impact or heavy loads. Furthermore, aluminum exhibits a high resistance to corrosion, making it an excellent choice for outdoor or marine applications where plastic may deteriorate over time. Furthermore, aluminum proves to be an exceedingly recyclable material, aligning with the increasing emphasis on sustainability and waste reduction. Unlike plastic, which can take centuries to decompose, aluminum can be recycled indefinitely without compromising its properties. This renders aluminum a more environmentally-friendly option for applications where plastic waste is a concern. Moreover, aluminum sheets offer superior thermal conductivity in comparison to plastic, making them ideal for applications that necessitate heat dissipation or thermal management. As a result, aluminum emerges as the preferred choice for products like heat sinks or electronic enclosures. However, it is crucial to acknowledge that aluminum sheets may not always be the optimal alternative to plastic. Plastic possesses its own set of advantages, such as its lightweight nature, flexibility, and cost-effectiveness, rendering it more suitable for applications that require these properties. Additionally, plastic can be molded into intricate shapes, making it preferable for certain designs. In conclusion, aluminum sheets can prove to be an effective substitute for plastic in specific applications where their strength, durability, corrosion resistance, recyclability, or thermal conductivity offer advantages. Nevertheless, the ultimate decision between aluminum and plastic hinges upon the specific requirements and limitations of the given application.

- Q: Can aluminum sheets be used for heat dissipation?

- Indeed, heat dissipation can be achieved by employing aluminum sheets. Renowned for its outstanding thermal conductivity, aluminum effectively conducts heat away from its origin, rendering it highly sought-after in numerous industries for heat sinks and heat exchangers. By molding and shaping aluminum sheets into diverse arrangements, surface area can be maximized, thereby augmenting heat dissipation. Additionally, the lightweight and corrosion-resistant characteristics of aluminum render it a favored material for applications involving heat dissipation.

- Q: How is an aluminum sheet manufactured?

- An aluminum sheet is manufactured through a process called rolling, where a large ingot of aluminum is heated and passed through a series of rollers to reduce its thickness and increase its length. This continuous rolling process is repeated until the desired thickness is achieved, and the aluminum sheet is then cut into various sizes and shapes.

- Q: which has greater density 5 kg of lead or 10 kg of aluminum

- The density of ANY amount of lead is greater than the density of ANY amount of aluminum. So even if we have a tiny speck of lead, and a truckload of Aluminum the lead still has greater density. The density of a substance does not depend on how much of it we have. One drop of water have a density of 1g/cm^3 and an ocean of water have exactly the same density of 1g/cm^3. The only difference is that the drop of water has less mass than the ocean, hence it would be easier to fetch; and the drop also has less volume hence it takes up less space.

- Q: will it influence powder injection effect after wiping the oil contamination on the surface of aluminum sheet?

- the surface should be kept clean to avoid the influence of oil contamination.

- Q: On candle when candle flame is about 1.000 degrees celsius and melting point of aluminum is 660 degrees celsius.

- If you are using tinfoil it is because it is coated with aluminum oxide which has a melting point of 2,000 degrees celcius.

- Q: What are the different methods of polishing aluminum sheets?

- Polishing aluminum sheets can be done through various methods, each with its own pros and cons. Here are some commonly used techniques: 1. Manual polishing: By employing sandpaper or abrasive pads, one can manually rub the surface of the aluminum sheet to achieve a high level of shine and smoothness. However, this method demands physical effort and can be time-consuming, especially for larger sheets. Careful execution is crucial to avoid leaving behind scratches or marks. 2. Chemical polishing: Dissolving a thin layer of the aluminum surface using chemical compounds can result in a smoother and shinier finish. This method is suitable for larger sheets or complex shapes where manual polishing is impractical. However, chemical handling must be meticulous, and it may not be suitable for certain aluminum alloys. 3. Electropolishing: An electrochemical process involving the use of an electric current to remove a thin layer of material from the aluminum surface. This method guarantees a smooth and shiny finish for both small and large sheets. It is particularly effective in eliminating surface imperfections and achieving a uniform appearance. However, specialized equipment and expertise are required to properly control the process. 4. Vibratory finishing: Placing aluminum sheets in a vibratory machine with abrasive media, like ceramic or plastic chips, can help remove surface imperfections and achieve a polished finish. This method is ideal for large batches of sheets and can be cost-effective. Nevertheless, it may not produce the same level of shine as other methods. 5. Buffing and polishing compounds: These compounds are applied to the aluminum sheets and then buffed using a rotary tool or polishing machine. The abrasive particles in the compounds aid in removing scratches and enhancing the metal's shine. This method is relatively quick and easy, but it may not be as effective for significant oxidation or deep scratches. Ultimately, the choice of polishing method depends on factors such as the size and type of the aluminum sheets, desired level of shine, and available equipment and expertise. It is advisable to test different methods on a small area before proceeding with the full polishing process to ensure satisfactory results.

- Q: What is the fatigue life of aluminum sheets?

- The fatigue life of aluminum sheets refers to the number of cycles that the material can withstand before failure occurs under cyclic loading conditions. The fatigue life of aluminum sheets can vary depending on various factors such as the alloy composition, thickness, surface finish, loading conditions, and environmental factors. Aluminum is known for its relatively high fatigue strength compared to other materials, making it a popular choice in various industries including aerospace, automotive, and construction. The fatigue life of aluminum sheets is typically influenced by the presence of microstructural defects such as inclusions, voids, and grain boundaries. To determine the fatigue life of aluminum sheets, fatigue tests are conducted using standardized procedures such as ASTM E466 or ASTM E606. These tests involve subjecting the material to cyclic loading conditions, typically at a constant stress or strain amplitude, while monitoring the number of cycles required for failure to occur. The results are then used to generate an S-N curve, which represents the relationship between the applied stress or strain amplitude and the number of cycles to failure. The S-N curve provides valuable information about the fatigue life of aluminum sheets, indicating the stress or strain levels at which the material can withstand a certain number of cycles before failure. It is important to note that the fatigue life of aluminum sheets can be improved through various methods such as alloying, heat treatment, surface treatment, and proper design considerations. In conclusion, the fatigue life of aluminum sheets is a critical factor to consider when designing components or structures subjected to cyclic loading conditions. Understanding the specific properties and characteristics of the aluminum alloy, along with proper testing and analysis, can help determine the fatigue life and ensure the safe and reliable performance of aluminum sheets in various applications.

- Q: Can aluminum sheets be used for elevator interiors?

- Yes, aluminum sheets can be used for elevator interiors. Aluminum is a commonly used material in elevator construction due to its durability, lightweight nature, and aesthetic appeal. It provides a sleek and modern look to elevator interiors while also offering high resistance to corrosion and wear.

Send your message to us

Aluminum Alloy 5052 Sheets - Big Five Bars for Different Usages

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords