JISG3192 galvanized angle steel for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

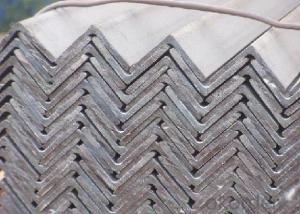

Specifications of Equal Angle Steel

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2.Length:6m,9m,12m

3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

.

4.Sizes:

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

5. Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Equal Anlge Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

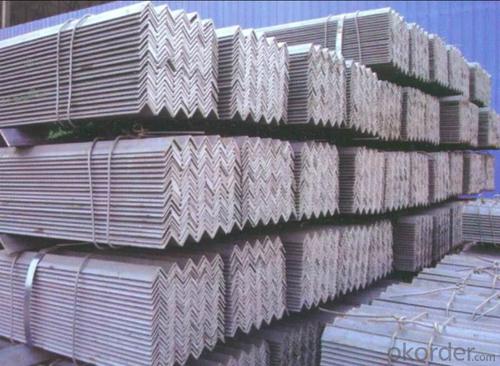

Packaging & Delivery of Equal Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q: Can steel angles be used in outdoor or corrosive environments?

- Steel angles have the capability to be utilized in outdoor or corrosive settings. They are frequently manufactured from either low carbon steel or stainless steel, both of which possess exceptional resistance against corrosion. Moreover, the application of coatings such as galvanization or painting can provide further protection against corrosion for steel angles. These protective coatings establish a barrier between the steel and the corrosive elements present in the environment, effectively averting rust and deterioration. Consequently, steel angles find widespread application in outdoor structures, including bridges, buildings, and industrial facilities, where they are exposed to moisture, saltwater, or other corrosive elements.

- Q: Can steel angles be used for soundproofing applications?

- Steel angles are not typically used for soundproofing applications. Soundproofing materials are chosen based on their ability to absorb, dampen, or block sound waves. Steel angles, being a rigid and reflective material, do not possess these sound-dampening qualities. Instead, materials such as acoustic foam, mass-loaded vinyl, or soundproof drywall are commonly used for soundproofing purposes. These materials are specifically designed to absorb or block sound waves, helping to reduce noise transmission between spaces. Therefore, while steel angles may have various applications in construction and engineering, they are not suitable for soundproofing purposes.

- Q: How do you calculate the shear capacity of a steel angle?

- The shear capacity of a steel angle can be calculated using the formula: Shear Capacity = 0.6 * Fy * Ag, where Fy is the yield strength of the steel and Ag is the gross area of the angle.

- Q: What are the different tolerances for steel angles?

- The different tolerances for steel angles can vary depending on the specific industry standards and requirements. Generally, tolerances for steel angles may include measurements for dimensions such as length, width, thickness, and straightness. These tolerances ensure that the steel angles meet the desired specifications and can be properly utilized in various applications.

- Q: What is the typical thickness of the base of a steel angle?

- The base thickness of a steel angle can vary depending on its specific application and requirements. Typically, the base thickness of a steel angle ranges from 1/8 inch to 3/8 inch. It is worth mentioning that this range is not comprehensive, and there may be instances where the base thickness deviates from these parameters. Elements such as the steel angle's size, load-bearing capacity, and intended purpose will impact the necessary base thickness for a particular project or structure. As a result, consulting engineering specifications or seeking professional guidance is crucial in determining the suitable base thickness for a steel angle in a specific application.

- Q: What are the limitations of using steel angles in corrosive or saltwater environments?

- The main limitations of using steel angles in corrosive or saltwater environments are their susceptibility to corrosion and potential for accelerated deterioration. Steel angles are prone to rusting and corrosion when exposed to moisture and saltwater, which can weaken the structural integrity of the material over time. To mitigate these limitations, protective coatings or alternative materials such as stainless steel or galvanized steel can be used.

- Q: Are steel angles available in pre-galvanized form?

- Yes, steel angles are available in pre-galvanized form. Pre-galvanized steel angles have been coated with a layer of zinc before being formed into angles. This galvanized coating provides protection against corrosion, making pre-galvanized steel angles ideal for outdoor and high-moisture environments. The pre-galvanized coating also adds a decorative element to the steel angles, giving them a shiny, metallic appearance. Pre-galvanized steel angles are commonly used in construction, infrastructure projects, and various industrial applications where strength, durability, and corrosion resistance are required.

- Q: How do you calculate the axial load capacity of a steel angle?

- To calculate the axial load capacity of a steel angle, you need to consider several factors such as the material properties of the steel angle, the cross-sectional area of the angle, the length of the angle, and the type of loading it will experience. The axial load capacity can be determined by analyzing the buckling and yielding behavior of the angle under compression or tension, using relevant equations or design standards specific to steel angles. It is recommended to consult engineering references, structural design codes, or seek professional assistance to accurately calculate the axial load capacity of a steel angle.

- Q: What are the common connection methods for steel angles?

- The common connection methods for steel angles include bolting, welding, and using mechanical fasteners such as screws or rivets. These methods ensure a secure and stable connection between steel angles, allowing them to be used effectively in various structural applications.

- Q: Can steel angles be used for roof trusses?

- Yes, steel angles can be used for roof trusses. Steel angles are commonly used in construction for their strength and durability. They can be easily fabricated and installed to create the framework for roof trusses. Steel angles provide excellent support and stability, making them suitable for use in various roofing applications. Additionally, steel angles can withstand heavy loads and adverse weather conditions, making them a reliable choice for roof trusses.

Send your message to us

JISG3192 galvanized angle steel for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords