SS400 galvanized angle steel for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

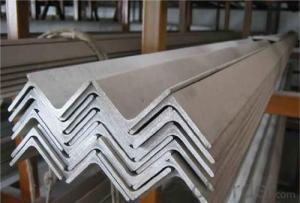

1. Structure of Steel Equal Angle Bar Description:

Steel equal angle bar is a main kind of structure steel and the section is like a letter L. We use steel equal angle bar for tower construction. Steel equal angle bar can be erected as soon as the materials are delivered on site. High strength, stiffness, toughness, and ductile properties are advantages of this kind of steel equal angle bar.

2. Main Features of Steel Equal Angle Bar:

• Strength - Having high strength, stiffness, toughness, and ductile properties, structural steel is one of the most commonly used materials in commercial and industrial building construction.

• Constructability - Steel equal angle Bar can be developed into nearly any shape, which are either bolted or welded together in construction. Structural steel can be erected as soon as the materials are delivered on site, whereas concrete must be cured at least 1–2 weeks after pouring before construction can continue, making steel a schedule-friendly construction material.

• Fire resistance - Steel is inherently a noncombustible material. However, when heated to temperatures seen in a fire scenario, the strength and stiffness of the material is significantly reduced. The steel equal angle bar can be enveloped in sufficient fire-resistant materials, increasing overall cost of steel structure buildings.

3. Steel Equal Angle Bar Images:

4. Steel Equal Angle Bar Specification:

Angle | KG/M | Angle | KG/M | Angle | KG/M | Angle | KG/M |

20X20X3 | 0.889 | 60X60X5 | 4.570 | 90X90X8 | 10.946 | 130X130X12 | 23.600 |

20X20X4 | 1.145 | 60X60X6 | 5.427 | 90X90X9 | 12.220 | 130X130X13 | 25.400 |

25X25X2 | 0.763 | 63X63X4 | 3.907 | 90X90X10 | 13.476 | 130X130X14 | 27.200 |

25X25X3 | 1.124 | 63X63X5 | 4.822 | 90X90X15 | 15.940 | 130X130X16 | 30.900 |

25X25X4 | 1.459 | 63X63X6 | 5.721 | 100X100X6 | 9.366 | 140X140X10 | 21.488 |

30X30X2 | 0.922 | 63X63X8 | 7.469 | 100X100X7 | 10.830 | 140X140X12 | 25.522 |

30X30X3 | 1.373 | 63X63X10 | 9.151 | 100X100X8 | 12.276 | 140X140X14 | 29.490 |

30X30X4 | 1.786 | 70X70X4 | 4.372 | 100X100X10 | 15.120 | 140X140X15 | 31.451 |

36X36X3 | 1.656 | 70X70X5 | 5.397 | 100X100X12 | 17.898 | 140X140X16 | 33.393 |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about the corrosion of the products?

When the steel equal angle bar in contact with water, can corrode, creating a potentially dangerous structure. Measures must be taken in structural steel construction to prevent any lifetime corrosion. The steel can be painted, providing water resistance. Also, the fire resistance material used to envelope steel is commonly water resistant.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③What is the difference between steel angle bar and traditional material?

Steel equal angle bar differs from concrete in its attributed compressive strength as well as tensile strength.

- Q: What are the welding techniques used for steel angles?

- Some common welding techniques used for steel angles include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), and flux-cored arc welding (FCAW). These techniques are effective in joining steel angles due to their ability to provide strong and durable welds.

- Q: Can steel angles be recycled?

- Yes, steel angles can be recycled. Steel is one of the most recycled materials in the world, and steel angles can be recycled through various processes such as melting and refining, which allows them to be used in the production of new steel products. Recycling steel angles helps conserve natural resources, reduces energy consumption, and minimizes waste.

- Q: Can steel angles be used for fencing or gating?

- Certainly, fencing or gating can indeed utilize steel angles. Steel angles are incredibly versatile and frequently employed in various construction endeavors, such as fencing and gating. They possess the essential attributes of strength, durability, and stability that are imperative for these particular applications. The assembly of a robust framework for fencing panels or gates can be effortlessly achieved by welding or bolting steel angles together. Moreover, these angles can be galvanized or coated to augment their resistance against corrosion, rendering them highly suitable for outdoor utilization. All in all, steel angles present a dependable and economically viable resolution for fencing and gating projects.

- Q: What are the different types of steel angles used in storage tank construction?

- Storage tank construction commonly utilizes several different types of steel angles, each serving a crucial role in providing structural support and stability. 1. L-angles, also referred to as unequal angles, find wide usage in storage tank construction. Comprising one longer and one shorter side, these angles form an L-shape. They are frequently employed as tank stiffeners, effectively preventing deformation and maintaining structural integrity. 2. T-angles, alternatively known as tee angles, represent another type of steel angle employed in storage tank construction. With a T-shape, one side is long while the other is shorter and perpendicular. T-angles often function as horizontal and vertical bracing members within tank structures, delivering added strength and stability. 3. Equal angles, also called right angles, consist of two equal sides forming a 90-degree angle. Tank construction commonly utilizes equal angles in various applications, such as providing support for tank roofs, reinforcing corners, or connecting tank components. 4. Bulb angles, or bulb flats, boast a unique shape featuring a flat surface and a bulbous section at one end. These angles are frequently employed in tank support structures, notably the tank bottom, to evenly distribute loads and minimize stress concentrations. 5. Rolled steel sections, such as I-beams, channels, and H-beams, are additionally utilized in storage tank construction alongside the aforementioned angle types. Rolled steel sections offer supplementary strength and support to tank structures, particularly in larger tanks or areas with high load requirements. In summary, the choice of steel angles in storage tank construction hinges upon specific design requirements, load considerations, and structural integrity needs. Selecting the appropriate type and size of angles is crucial to ensure tanks can withstand anticipated loads and environmental conditions.

- Q: How do steel angles compare to wooden or concrete structural elements?

- Steel angles have several advantages over wooden or concrete structural elements. Firstly, steel angles have a higher strength-to-weight ratio, making them capable of supporting heavier loads with less material. This allows for more efficient structural designs and reduces the overall weight of the structure. Additionally, steel angles have better resistance to fire, pests, and moisture, eliminating concerns related to rotting, termite damage, or decay. Moreover, steel angles provide greater flexibility in terms of design and can be easily modified or extended if needed. Lastly, steel angles offer increased durability and longevity, requiring less maintenance and having a longer lifespan compared to wooden or concrete elements.

- Q: How do steel angles perform under dynamic loads?

- Steel angles generally perform well under dynamic loads due to their inherent strength and durability. The structural shape of steel angles, characterized by their L-shaped cross-section, provides excellent resistance to bending and torsional forces. This design allows them to efficiently distribute dynamic loads and resist deformation, making them suitable for various applications in construction, engineering, and manufacturing industries. However, the specific performance of steel angles under dynamic loads can vary depending on factors such as the grade and quality of the steel, the magnitude and frequency of the dynamic load, and the overall design and reinforcement of the structure.

- Q: What are the different methods of protecting steel angles against corrosion?

- There are several methods available for protecting steel angles against corrosion. The choice of method depends on factors such as the environment, budget, and desired lifespan of the steel angles. Here are some of the commonly used methods: 1. Coatings: Applying protective coatings is one of the most effective methods to prevent corrosion. Coatings like paint, epoxy, or polyurethane create a barrier between the steel surface and the corrosive elements. These coatings should be applied in multiple layers to ensure adequate protection. Regular inspections and touch-ups may be required to maintain the coating's integrity. 2. Galvanization: Galvanizing steel angles involves coating them with a layer of zinc. This method creates a sacrificial barrier that corrodes before the steel does. Galvanization is highly effective in protecting against corrosion, especially in harsh environments. However, it may not be suitable for aesthetic applications as the zinc layer can change the appearance of the steel. 3. Stainless Steel: Using stainless steel angles is another way to protect against corrosion. Stainless steel contains a high percentage of chromium, which forms a passive layer on the surface, protecting it from corrosion. Stainless steel is particularly useful in corrosive environments such as marine or chemical industries. 4. Powder Coating: Powder coating involves applying a dry powder to the steel angles and then heating it to create a protective layer. This method offers excellent corrosion resistance and can provide a decorative finish as well. Powder coating is commonly used in architectural applications where aesthetics are important. 5. Cathodic Protection: Cathodic protection is an electrochemical method that prevents corrosion by making the steel angle a cathode in a galvanic cell. This is achieved by connecting the steel to a sacrificial anode, usually made of a more reactive metal like zinc or magnesium. The anode corrodes instead of the steel angle, providing protection. 6. Regular Maintenance: Regardless of the protective method used, regular inspection and maintenance are essential. This includes cleaning the steel angles, removing any debris or corrosive substances, and promptly repairing any damaged or scratched coatings. Regular maintenance helps to identify and address any early signs of corrosion, ensuring the prolonged lifespan of the steel angles. It is important to consult with corrosion experts or engineers to determine the most suitable method for protecting steel angles based on the specific requirements and conditions.

- Q: How do you determine the load-bearing capacity of a steel angle?

- To determine the load-bearing capacity of a steel angle, several factors need to be considered. Firstly, the material properties of the steel angle must be known, such as its yield strength and ultimate tensile strength. These values can be obtained from the manufacturer or from relevant material standards. Next, the dimensions and shape of the steel angle play a crucial role in determining its load-bearing capacity. The angle's thickness, width, and length should be measured accurately. Additionally, the angle's shape, whether it is equal or unequal, must also be taken into account. Once these properties are known, the load-bearing capacity can be calculated using engineering principles and structural analysis methods. One common approach is to use the Euler's formula, which considers the bending and axial loads on the steel angle. The Euler's formula states that the load-bearing capacity of a steel angle is proportional to its moment of inertia and the modulus of elasticity. These values are calculated based on the dimensions and shape of the angle. Furthermore, other factors such as the angle's end supports, the type of loading (e.g., concentrated load or uniformly distributed load), and any additional factors of safety must be taken into consideration. It is important to note that determining the load-bearing capacity of a steel angle is a complex process that requires expertise in structural engineering. Therefore, it is recommended to consult with a qualified engineer or refer to relevant design codes and standards to ensure accurate and safe calculations.

- Q: Are steel angles suitable for manufacturing support brackets for conduits?

- Yes, steel angles are commonly used for manufacturing support brackets for conduits due to their strength, durability, and ability to provide structural support.

- Q: Can steel angles be used as reinforcement in concrete structures?

- Yes, steel angles can be used as reinforcement in concrete structures. Steel angles are commonly used as a cost-effective and efficient solution for providing additional strength and support to concrete elements. They can be embedded or welded into the concrete to enhance its load-bearing capacity and improve overall structural integrity.

Send your message to us

SS400 galvanized angle steel for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords