Ceiling Fiberglass Insulation Roof Ceiling Design

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

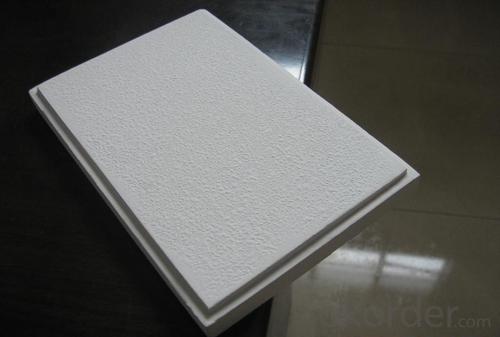

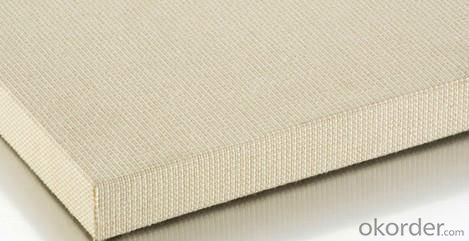

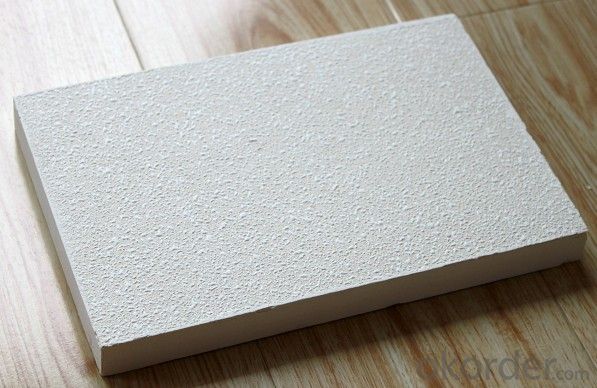

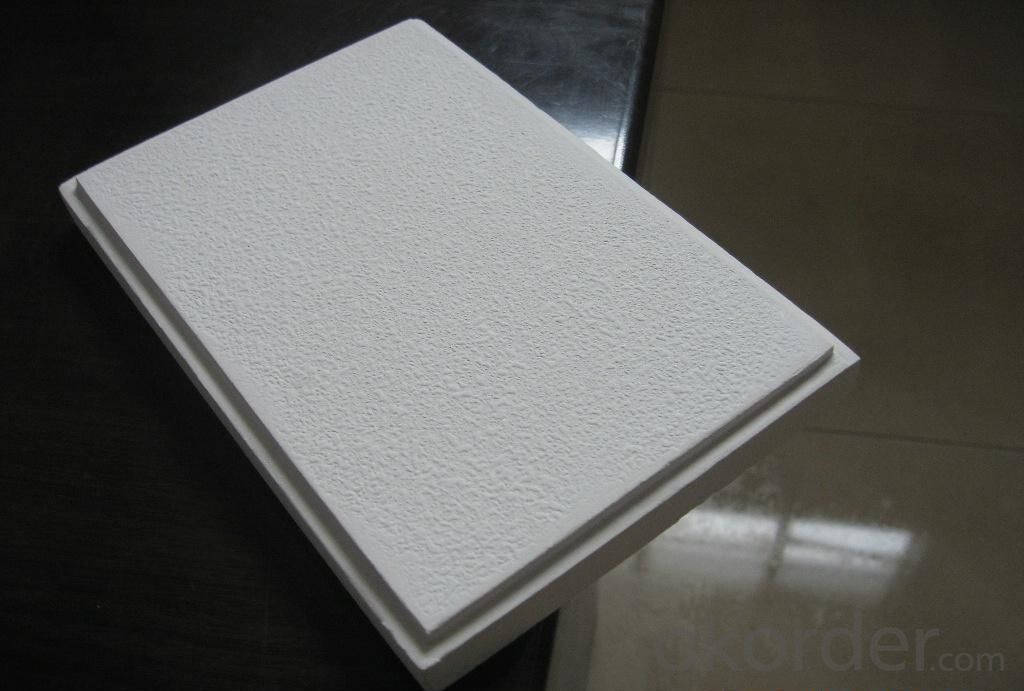

The tile is made by high-density fiberglass with compound decoration wool on the surface and fiberglass wool on the back .The edges are painted. With the characteristics of square in edges and angle,it will be parallel to suspension system after installation.

Product Applications:

office building, commercial facilities,

shopping mall, Airport and school,Halls etc.

Product Advantages:

1)Incombustibility/Non-flammability: Consmos Calcium silicate board is non-flammable and conforms to the national grade A standard (GB8624 Grade A) with excellent fire resistance property. In case of fire, the board will not burn and not give off toxic smoke.

(2)Thermal/heat insulation: Owing to low heat conductivity, the product has good performances on keeping warm and heat insulation.

(3)Water-proofing and moistureproof: The product is allowed to long-term exposure to moist environment but still very stable. The board still keeps intact after being soaked in water for one month, the phenomenon of swelling and out of shape will not happen. It has good adjusting mechanics like woods. Even it is used on wash house.

(4)Endurance/durability: Consmos Calcium silicate board provides good insulation against bugs, fungus and corrosion. It can last for a long time and will not corrode.

(5)Noise-proofing: Consmos Calcium silicate board provides good insulation against noise.

(6)High-Strength and Light weight: The board is light weight, in this case, it can decrease weight of building greatly. At the same time, the material is high-stength and not easy to be damaged.

Main Product Features:

1) Use fiberglass wool as raw material

2) Good photopathy, noise and thermal insulation, fire resistance, easy to install and maintenance

3) Widely used in the places with special requirements to light

4) Edges: square, tegular, concealed

5) NRC: 0.8 - 1.0

6) Level of fireproofing:A2

Raw material: level A (incombustible class)

b) Surface: A2 flame( resistant class)

7) Coefficient of heat preservation: 0.046W / (M.K)

8) Radioactive species limitation: None

Product Specifications:

FAQ:

1)Q:Are you a factory or trading company?

A: We are a factory.

2)Q: I am interested in the products but I do not have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

3)Q: How can I get some samples?

A: We are honored to offer you samples.

4)Q:How does your factory do regarding quality control?

A: Quality is priority, we always attach great importance to quality controlling from every worker to

the very end.

Images:

- Q: If you were a single woman with no man around, how would you fix a hole in the ceiling from water damage? And the roof? On a budget. Is this possible for a small woman to do this job by herself? Can someone give me step by step instructions? Photo of the damage attatched.

- I would repair it. It is not terribly difficult or costly - but your circumstance is complicated by the texture on the ceiling. You would need to purchase some lightweight joint compound, some fiberglass reinforcing mesh or tape, a couple of inexpensive plastic spackling knives (and you will need either a step-ladder or some other stable platform to work from. You will clean out the damaged area and remove all loose materials. Then use a knife to spread some joint compound in the hole, not too much but enough to cover everything with a thin coat. Spread the reinforcing material over this and add a small amount more compound. Smooth this as best you can with a knife. Allow to cure overnight. Repeat with thin coats of compound only until smooth. Sand lightly to remove tool marks. Now you have as smooth area in a textured area. There are texture-sprays-in-a-can that you can try, or you can just leave it smooth, Paint. Done. It takes some time, and you will learn as you go - so don't expect perfection right away. Good luck with it.

- Q: Why is the state of magnesium dichloride at room temperature?

- Solid, is a crystal.

- Q: we have numerous recessed light fixtures in our ceiling. Is fiberglass insulation flammable?

- Do you have the paper on the insulation? You should not have the insulation right up to the fixture.The fiberglass is not flamable, but it can melt if it gets too hot

- Q: Fireproof fireproof glass fireproof shutter door What is it?

- You can be very intuitive to understand the fire resistance for the decorative parts, fire cut off, fire glass, fire shutter doors have in common, that is played an effective isolation; it is both functional, but also has the role of split space!

- Q: We just had our first child, and his room is right above the garage. It is noticebly colder in his room, especially the floor. I used the plastic window kits and that helped, however, the floor is still extremely cold and I would like to at least check the insulation in the garage ceiling. Right now there is drywall on the ceiling, but I have no qualms about ripping it down, not real worried what it looks like. What should I look for...I believe there is very old (50 years) fiberglass insulation but i'm not 100% sure. If there is the old insulation there...should I look to replace it? If so, with what R value...Is this a project that someone without specific experience in the field could complete? I'm pretty handy but certainly not a pro. I'm not worried at all how it looks in the garage.

- There is a big debate with vapor and no vapor barrier depending on where you live. Check your local codes. You can have insulation blown in. A fast DiY if there is no aesthetic issue in the garage is to put up fiberglass sheeting on the ceiling which will be quick but effective fix.

- Q: I had the roof replaced last summer, but havent had the energy to get up there and take down the ceiling tiles and the fiberglass insulation. I started removing it a section at a time a week ago, and wow! What a mess!. Gravel is falling down on my head and the insulation and tiles are dry now, but its still hard to pull them out. Should I be wearing a mask? Is there anything in the old dried out insulation and ceiling tiles that I should cover my nose? Its making a really big mess, so any suggestions will be helpful.

- You should absolutely weat a mask! There's fiberglass in there you said and you don't want that in your lungs along with all the dust and dirt. Fiberglass never disolves and it is made from glass.

- Q: What are the characteristics of the use of fiberglass ceilings?

- I have a voice, because my home is the Jiangsu Sanxian Architectural Acoustics System Co., Ltd. production of fiberglass ceiling

- Q: What is fiberglass?

- Fiberglass is the whitewashed wall is the time in the mortar to add some fiberglass so that after the powder up the glass and then pull the wall will not crack this thing is very good use of our site to use the external walls of the whole The wall is much clearer

- Q: What is the candle effect?

- For the natural phenomenon, there is a relatively reasonable explanation, known as the candle effect. Scientists believe that we can put a person wearing clothes, conceived as a candle inside and outside, clothes are candle, body fat is wax. Even a small flames may penetrate the skin, ignite the fat, and then slowly and continuously burn. ????Candle effect proved that the body itself has a burning source, as long as the environmental conditions meet, the human body can self-destruction. Is considered a case of spontaneous combustion in the body there is a frequent clue: smoking. Scientists believe that smoking may accidentally ignite what, most likely the bed of things; then, by the carbon monoxide choking faint, then, the fire into the skin, lit fat, people into a slow burning candles. The clothes and sheets are like candles, and the fat is wax. The heat of the fire is not high enough, so no other items in the room are burned. ????The truth is that no one has ever witnessed a person or an animal to burn himself and to ashes. Worse still: in the case of suspected spontaneous combustion of the human body, the victims are mostly elderly, weak people, often overweight, smoking and other issues, and are living alone.

- Q: But it's fiberglass and needs to be flexible for when it moves. I think actual mirrors will crack and be too heavy. What do I use for the mirrored effect?

- a fabric called mylar. The material most ballons are made from.

Send your message to us

Ceiling Fiberglass Insulation Roof Ceiling Design

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords