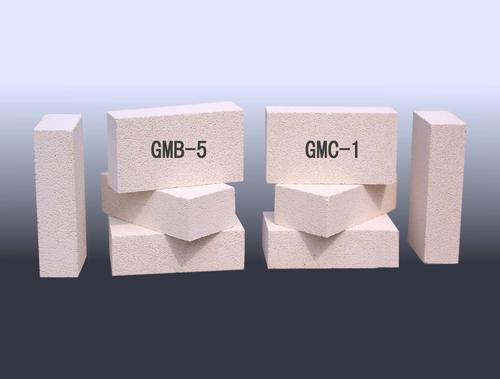

Insulating Fire Brick B5

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

- Q: Can insulating fire bricks be used in the construction of glassware production furnaces?

- Insulating fire bricks are capable of being used in the construction of furnaces for glassware production. These fire bricks are specially designed to possess low thermal conductivity, enabling them to tolerate extreme temperatures while effectively providing insulation. This quality makes them highly suitable for deployment in furnaces dedicated to glassware production, as they aid in heat retention and minimize energy wastage. Moreover, these fire bricks exhibit resistance to thermal shock, which is vital in glassware production where sudden temperature fluctuations can arise. In summary, the incorporation of insulating fire bricks in the construction of furnaces for glassware production ensures the equipment operates efficiently and safely.

- Q: What is a JQK composite lightweight thermal insulation brick?

- 1. structural layer2. leveling layer3. waterproof layer4. thermal insulation layer and decorative layer

- Q: What is the typical cost of insulating fire bricks?

- The typical cost of insulating fire bricks ranges from $2 to $5 per brick, depending on the quality, size, and quantity needed.

- Q: Can insulating fire bricks be used in the construction of combustion chambers?

- Yes, insulating fire bricks can be used in the construction of combustion chambers. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for containing and directing heat in combustion processes.

- Q: Can insulating fire bricks be used in the construction of ceramic tile kilns?

- Insulating fire bricks are suitable for constructing ceramic tile kilns. These bricks are specially designed to endure elevated temperatures and possess exceptional insulation properties. By having low thermal conductivity, they effectively trap heat inside the kiln, preventing its escape and enhancing the firing process of ceramic tiles. Moreover, their lightweight quality makes them convenient to handle and install within the kiln structure. Ultimately, incorporating insulating fire bricks in the construction of ceramic tile kilns enhances energy efficiency, diminishes heat loss, and guarantees consistent and regulated firing temperatures.

- Q: Are insulating fire bricks easy to handle and install?

- Insulating fire bricks are generally easy to handle and install. They are lightweight, making them easy to transport and carry around. Additionally, their shape and size are designed to be user-friendly, allowing for easy manipulation and installation. Most insulating fire bricks come with pre-drilled holes or grooves, which further simplifies the installation process. Moreover, these bricks can be easily cut or shaped to fit specific dimensions or requirements, making them highly versatile. Overall, insulating fire bricks are considered easy to handle and install, even for individuals with limited experience or knowledge in masonry work.

- Q: What are the sizes of lightweight thermal insulation bricks?

- The production of material ordinary lightweight insulating refractory brick with fireclay and high alumina high strength bead brick

- Q: Can insulating fire bricks be used in wastewater treatment plants?

- Yes, insulating fire bricks can be used in wastewater treatment plants. Insulating fire bricks are designed to withstand high temperatures, making them suitable for use in various industrial applications, including wastewater treatment plants. They are commonly used in the construction of kilns, furnaces, and other high-temperature equipment. In wastewater treatment plants, insulating fire bricks can be used in the construction of incinerators, thermal oxidizers, and other systems that require high-temperature insulation. Their properties, such as high thermal resistance, low thermal conductivity, and excellent insulation capabilities, make them ideal for maintaining the desired temperatures in these systems while minimizing heat loss. Additionally, insulating fire bricks are resistant to chemical attacks, which is important in wastewater treatment plants where various chemicals and corrosive substances are present. Overall, the use of insulating fire bricks in wastewater treatment plants can help improve energy efficiency, reduce maintenance costs, and ensure the longevity of high-temperature equipment.

- Q: Can insulating fire bricks be used in the construction of boilers for power plants?

- Yes, insulating fire bricks can be used in the construction of boilers for power plants. These bricks have excellent insulating properties, which help to retain heat and increase energy efficiency in the boilers. Additionally, their lightweight nature reduces the overall weight of the construction, making them a suitable choice for power plant boilers.

- Q: What is the maximum temperature that insulating fire bricks can withstand?

- Insulating fire bricks can withstand temperatures up to 3000°F (1650°C).

Send your message to us

Insulating Fire Brick B5

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords