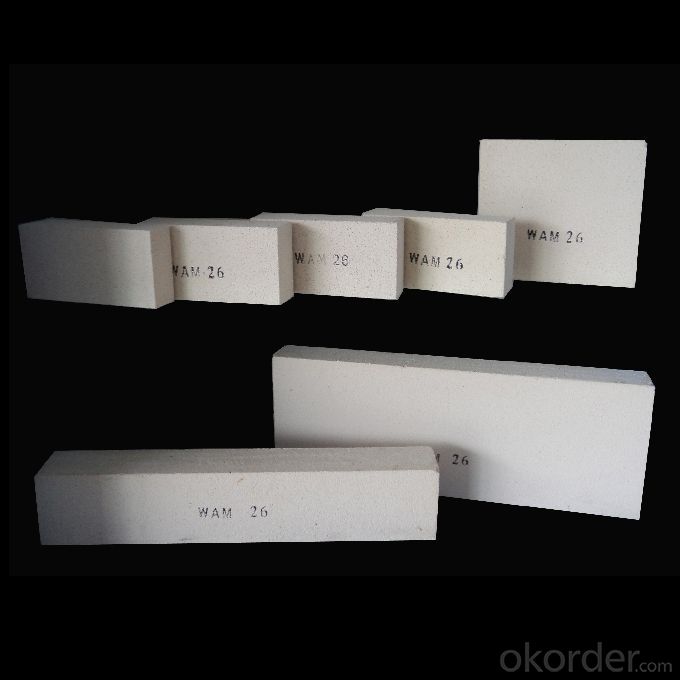

Insulating Fire Brick - Refractory Mullite GJM26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

- Q: Can insulating fire bricks be used in the construction of rotary kilns?

- Yes, insulating fire bricks can be used in the construction of rotary kilns. Insulating fire bricks are designed to provide high thermal insulation, making them ideal for applications where heat retention is important. In the construction of rotary kilns, insulating fire bricks can be used as a lining material to minimize heat loss from the kiln and improve its energy efficiency. Additionally, these bricks have good resistance to thermal shock, which is crucial in the high-temperature environment of a rotary kiln. Overall, using insulating fire bricks in the construction of rotary kilns can help enhance their performance and reduce energy consumption.

- Q: Can insulating fire bricks be used in refractory cement?

- Yes, insulating fire bricks can be used in refractory cement. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent insulation, while refractory cement is used to bind and seal refractory materials. By using insulating fire bricks in refractory cement, it can enhance the overall insulation properties and improve the performance of the cement in high-temperature applications.

- Q: Can insulating fire bricks be used in the construction of ceramic fiber-lined kilns?

- Indeed, the utilization of insulating fire bricks is possible for the construction of ceramic fiber-lined kilns. These specialized bricks are purposely designed to deliver exceptional insulation, rendering them ideal for situations that prioritize heat retention. By combining them with ceramic fiber lining, insulating fire bricks contribute to enhanced energy efficiency and diminished heat dissipation within kilns. Moreover, their lightweight nature and ease of handling facilitate simpler installation and construction of the kiln. Ultimately, the incorporation of insulating fire bricks in the construction of ceramic fiber-lined kilns positively impacts the kiln's overall performance and efficiency.

- Q: What is the porosity of insulating fire bricks?

- The porosity of insulating fire bricks typically ranges from 40% to 70%, allowing for excellent thermal insulation properties.

- Q: Can insulating fire bricks be used in ladles?

- Certainly! Ladles can indeed utilize insulating fire bricks. These bricks are specifically engineered to endure extreme temperatures while offering thermal insulation. They find frequent application in situations where the maintenance or regulation of high temperatures is necessary, like furnaces, kilns, and ladles. Ladles are employed for the purpose of pouring and transferring molten metal or other substances. By incorporating insulating fire bricks into ladles, heat loss is reduced and energy efficiency is enhanced. Moreover, these bricks serve as a safeguard against chemical reactions and erosion stemming from the molten materials, thus qualifying them as suitable for ladle usage.

- Q: Are insulating fire bricks suitable for use in carbon black furnaces?

- Yes, insulating fire bricks are suitable for use in carbon black furnaces. Insulating fire bricks are made from refractory materials that have excellent insulation properties, which makes them ideal for high-temperature applications such as carbon black furnaces. Carbon black furnaces operate at extremely high temperatures, typically above 1,000 degrees Celsius, and the use of insulating fire bricks helps to reduce heat loss and improve energy efficiency. These bricks also have good thermal shock resistance, which is crucial for the cyclic heating and cooling that occurs in the furnace. Additionally, insulating fire bricks have low thermal conductivity, which helps to maintain a stable temperature inside the furnace and prevent excessive heat loss. Overall, insulating fire bricks are a reliable and effective choice for lining carbon black furnaces.

- Q: Are insulating fire bricks suitable for use in coke ovens?

- Insulating fire bricks are not suitable for use in coke ovens. Coke ovens require bricks that can withstand extremely high temperatures and harsh chemical environments. Insulating fire bricks are designed to provide thermal insulation and are not able to withstand the heat and chemical exposure that occurs in coke ovens. Therefore, it is crucial to use refractory bricks specifically designed for coke ovens, which have high resistance to temperature, chemical attacks, and thermal shock. These refractory bricks are typically made from materials such as silica, alumina, and carbon, which can withstand the harsh conditions inside the coke ovens.

- Q: What are insulation bricks for? Do not use high-rise buildings on the ah?

- Heat preservation bricks are of course used for insulation... Tall buildings should not be used

- Q: Can insulating fire bricks be used in the construction of fireplaces?

- Yes, insulating fire bricks can be used in the construction of fireplaces. Insulating fire bricks are designed to withstand high temperatures, making them an ideal choice for lining the interior of a fireplace. They have excellent thermal insulation properties, helping to retain heat within the fireplace and prevent excessive heat transfer to the surrounding structure. This not only improves the efficiency of the fireplace but also reduces the risk of damage to the surrounding walls. Insulating fire bricks are lightweight and easy to handle, making them convenient for construction purposes. Additionally, they are resistant to thermal shock, meaning they can withstand rapid temperature changes without cracking or breaking. Overall, insulating fire bricks are a reliable and effective choice for constructing fireplaces.

- Q: Can activated carbon be antiseptic?

- In addition to activated carbon carbon, also contains two kinds of admixtures: one is the combination of chemical elements, mainly hydrogen and oxygen, these elements are due to incomplete carbonization and the residue in the carbon, or in the process of activation, non carbon and activated carbon surface chemical foreign combination, such as the use of water vapor when activated, the surface of the active carbon is oxidized or water vapor oxidation; another kind of admixture is ash, it is part of the inorganic carbon in ash; activated carbon is easy to cause two pollution.

Send your message to us

Insulating Fire Brick - Refractory Mullite GJM26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords