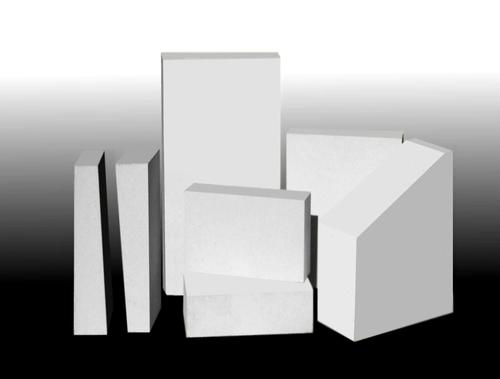

Advanced Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

- Q: Are insulating fire bricks suitable for high-temperature kilns?

- Insulating fire bricks prove to be a suitable option for high-temperature kilns due to their ability to withstand extreme heat while providing excellent thermal insulation. These bricks are specifically designed to meet the demands of kilns that operate at high temperatures. They are constructed using lightweight and porous materials like clay or silica, which possess low thermal conductivity. Consequently, heat is effectively trapped within the kiln, preventing any loss, while simultaneously offering insulation against the external environment. Furthermore, insulating fire bricks exhibit remarkable resistance to thermal shock, allowing them to endure sudden temperature fluctuations without any damage. Hence, these bricks are a dependable and efficient choice for high-temperature kilns.

- Q: What is the price of fireproof insulation material?

- Fire insulation materials are various, different specifications, grades of prices are different, according to market rules, there will be fluctuation, the most commonly used are insulation rock wool, insulation board, insulation bricks, fire blocking materials.

- Q: Are insulating fire bricks suitable for use in steel manufacturing plants?

- Insulating fire bricks are a suitable choice for steel manufacturing plants. Their excellent thermal properties, including high heat resistance and low thermal conductivity, make them ideal for high-temperature environments like steel manufacturing plants. These bricks can endure the extreme heat generated during steel production processes such as melting, casting, and forging. Furthermore, they assist in conserving energy by minimizing heat loss, thereby enhancing the overall efficiency of the plant. Additionally, they possess considerable mechanical strength and can withstand the physical stresses and strains associated with steel manufacturing operations. In summary, incorporating insulating fire bricks in steel manufacturing plants can enhance safety, boost productivity, and improve energy efficiency.

- Q: Can insulating fire bricks be used in the construction of hearth furnaces?

- Yes, insulating fire bricks can be used in the construction of hearth furnaces. Insulating fire bricks are specially designed to have low thermal conductivity, which makes them ideal for applications where heat insulation is required. In the construction of hearth furnaces, where high temperatures are involved, insulating fire bricks can help to retain the heat within the furnace and improve energy efficiency. They can also provide thermal protection to the surrounding structures by minimizing heat transfer. Additionally, insulating fire bricks are lightweight and easy to handle, which makes them convenient for construction purposes. Overall, using insulating fire bricks in the construction of hearth furnaces can enhance their performance and contribute to a more efficient and effective heating process.

- Q: Can insulating fire bricks be used in the construction of pottery extruders?

- Yes, insulating fire bricks can be used in the construction of pottery extruders. These bricks are known for their high heat resistance, low thermal conductivity, and excellent insulating properties, making them suitable for applications where high temperatures are involved, such as pottery extrusion. They can help maintain a consistent temperature within the extruder, ensuring optimal working conditions for the clay and improving overall efficiency.

- Q: Are insulating fire bricks resistant to thermal spalling?

- Insulating fire bricks exhibit resistance to thermal spalling, which is the process of a material cracking or fracturing as a result of abrupt fluctuations in temperature or thermal shock. These bricks are specifically engineered to endure elevated temperatures and thermal cycling without spalling. Their low thermal conductivity allows for efficient insulation against heat transfer, thereby reducing the strain caused by thermal expansion and contraction. Moreover, the composition and structure of insulating fire bricks are meticulously designed to offer outstanding protection against thermal spalling, rendering them a dependable option for applications involving intense heat conditions.

- Q: Can insulating fire bricks be used for insulation in furnaces?

- Yes, insulating fire bricks can be used for insulation in furnaces. Insulating fire bricks are made from lightweight materials such as clay and minerals, which have excellent thermal insulation properties. They are designed to withstand high temperatures, making them suitable for use in furnaces. These bricks help to reduce heat loss and improve energy efficiency by preventing the escape of heat from the furnace. Additionally, insulating fire bricks can also help to protect the outer structure of the furnace from excessive heat, thereby extending its lifespan. Overall, insulating fire bricks are a reliable and effective choice for insulation in furnaces.

- Q: Are insulating fire bricks resistant to weathering or aging?

- Yes, insulating fire bricks are generally resistant to weathering and aging. These bricks are designed to withstand high temperatures and harsh conditions, making them durable and long-lasting. They are often used in applications where exposure to extreme weather, such as rain, snow, and sunlight, is common. However, it is important to note that the specific composition and quality of the bricks can vary, so it is advisable to consult the manufacturer or supplier for detailed information regarding their weathering and aging resistance properties.

- Q: Can insulating fire bricks be used in kiln car construction?

- Yes, insulating fire bricks can be used in kiln car construction. These bricks possess excellent thermal insulation properties, making them suitable for creating an energy-efficient and temperature-stable environment inside the kiln. Additionally, their lightweight nature simplifies the construction process and allows for easy handling of kiln cars.

- Q: Can insulating fire bricks be used as a thermal barrier?

- Yes, insulating fire bricks can be used as a thermal barrier. These bricks have high thermal resistance and low thermal conductivity, making them effective in reducing heat transfer. They are commonly used in applications where thermal insulation is required, such as in furnaces, kilns, and fireplaces, to prevent heat loss and protect surrounding areas from excessive heat.

Send your message to us

Advanced Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords