Insulating Fire Brick - GJM32

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 pcs pc

- Supply Capability:

- 1000 Tons Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Insulating Fire Brick GJM32

Insulating fire brick GJM32 temperature is 1760℃(3200℉). We could supply a wide range of shapes. To make our firebricks more energy and cost effective, we have different manufacturing methods for our insulating fire bricks casting and extruding method.

For insulating fire bricks GJM32,we choose the extruding method. Extruding insulating fire bricks have better strength and offering great performance in load bearing applications and in conditions where abrasion from mechanical abuse or flow of hot gases.

Characteristics of Insulating Fire Brick GJM32

Our insulating bricks GJM32 exhibit the following characteristics:

High refractoriness temperature

Strong resistance to slag

Good high temperature properties

Typical Application of Insulating Fire Brick GJM32

Typical applications of magnesia bricks include ferroalloy furnace, metal mixer, Non-metallurgy industry furnace, high temperature kiln, calcined lime furnace, regenerator in glass furnace.

Technical Data of Insulating Fire Brick GJM32

|

| GJM32 |

Physical Properties: |

|

|

Classifiction Temperature | ℃ | 1650 |

Density | Kg/m3 | 1100 |

Cold Crushing Strength | Mpa | 3.5 |

Reheating Linear Change(24hrs) |

|

|

1650℃ | % | 0.8 |

Hot Load Strength Deform(90 minutes) |

|

|

1370℃ at 0.069 Mpa(10psi) | % | 0.1 |

Thermal Conductivity |

|

|

400℃ | W/m.k | 0.32 |

600℃ | W/m.k | 0.35 |

800℃ | W/m.k | 0.38 |

1000℃ | W/m.k | 0.42 |

1200℃ | W/m.k | 0.44 |

Specific Heat | KJ/Kg.K | 1.10 |

Chemical Analysis: |

|

|

Al2O3 | % | 75.0 |

SiO2 | % | 23.2 |

Fe2O3 | % | 0.5 |

TiO2 | % | 0.1 |

CaO | % | 0.1 |

MgO | % | 0.1 |

Na2O+K2O | % | 0.6 |

CNBM has success in insulating fire bricks due to their cost-effectiveness, excellent insulation performance and high temperature properties. CNBM also has experience in magnesia brick application and would like to assist you in product selection, system design, and installation techniques.

- Q: Can insulating fire bricks be used as insulation in walls and roofs?

- Yes, insulating fire bricks can be used as insulation in walls and roofs. Insulating fire bricks are made from lightweight materials that have excellent thermal insulation properties. They have low thermal conductivity, which means they can effectively reduce heat transfer through walls and roofs. This makes them a suitable choice for insulating buildings and improving energy efficiency. Additionally, insulating fire bricks are durable and fire-resistant, making them a safe option for insulation. However, it is important to note that insulating fire bricks are typically used in high-temperature applications such as furnaces and kilns, so they may not be the most cost-effective or practical choice for all wall and roof insulation needs. Other insulation materials designed specifically for building applications may be more suitable in terms of cost, ease of installation, and overall performance.

- Q: Can insulating fire bricks be used in metal smelting furnaces?

- Yes, insulating fire bricks can be used in metal smelting furnaces. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in furnaces where metal smelting occurs. They help maintain consistent heat levels and reduce heat loss, allowing for efficient and effective metal smelting processes.

- Q: Can insulating fire bricks be used for insulation in hot water tanks?

- Yes, insulating fire bricks can be used for insulation in hot water tanks. Insulating fire bricks are designed to have excellent thermal insulation properties, making them an ideal choice for insulating hot water tanks. These bricks can effectively prevent heat loss from the hot water tank, helping to maintain the temperature of the water for longer periods of time. Additionally, insulating fire bricks are highly durable and can withstand high temperatures without cracking or breaking, making them a reliable choice for hot water tank insulation.

- Q: Can insulating fire bricks be installed in both industrial and residential settings?

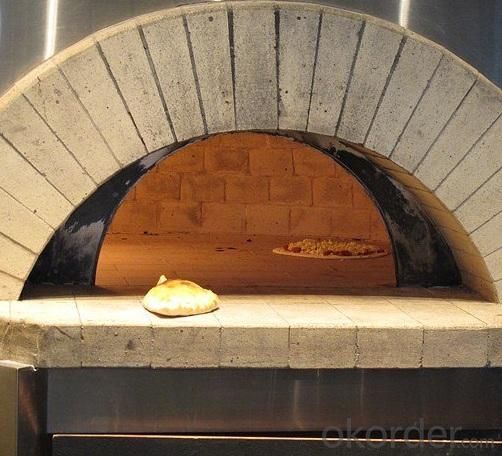

- Insulating fire bricks can be utilized in both industrial and residential environments. These bricks are specifically engineered to endure extreme temperatures and offer superb insulation, rendering them appropriate for various purposes. In industrial settings, insulating fire bricks are frequently employed in furnaces, kilns, and ovens, as they aid in conserving energy and ensuring stable temperatures. In residential settings, they can be employed in fireplaces, wood-burning stoves, and pizza ovens, enhancing heat retention and promoting safety. Due to their versatility and durability, insulating fire bricks are a dependable option for installations in both industrial and residential settings.

- Q: Can insulating fire bricks be used in metal melting furnaces?

- Yes, insulating fire bricks can be used in metal melting furnaces. These bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for use in metal melting furnaces where heat retention is crucial.

- Q: Can insulating fire bricks be used in the construction of ceramic tile kilns?

- Yes, insulating fire bricks can be used in the construction of ceramic tile kilns. These bricks are designed to have low thermal conductivity, which helps to retain heat within the kiln. This insulation property is crucial for maintaining high temperatures and consistent firing conditions in ceramic tile kilns. Additionally, insulating fire bricks are lightweight and durable, making them suitable for kiln construction.

- Q: Do insulating fire bricks require a protective coating for outdoor use?

- Yes, insulating fire bricks typically require a protective coating for outdoor use. This is because exposure to harsh weather conditions, moisture, and temperature fluctuations can potentially degrade the bricks over time. Applying a protective coating helps to enhance their durability and longevity when used outdoors.

- Q: Are insulating fire bricks suitable for use in the construction of blast furnaces?

- Yes, insulating fire bricks are suitable for use in the construction of blast furnaces. Insulating fire bricks are made from lightweight materials such as ceramics and have high insulating properties. These bricks have low thermal conductivity, which helps to reduce heat loss and increase efficiency in the blast furnace. Additionally, insulating fire bricks have excellent resistance to thermal shock, meaning they can withstand rapid changes in temperature without cracking or breaking. This is crucial in blast furnace construction, as the intense heat generated in the furnace can cause regular bricks to deteriorate quickly. Insulating fire bricks also have high compressive strength, ensuring their durability and longevity in the harsh conditions of a blast furnace. Overall, the use of insulating fire bricks in blast furnace construction can enhance energy efficiency, improve the performance of the furnace, and prolong its lifespan.

- Q: Are insulating fire bricks resistant to carbon monoxide?

- Yes, insulating fire bricks are resistant to carbon monoxide. These bricks are specifically designed to withstand high temperatures and are commonly used in applications where exposure to intense heat and chemicals, such as carbon monoxide, is expected. The insulating properties of these bricks make them highly resistant to heat transfer, allowing them to maintain their structural integrity in the presence of carbon monoxide and other combustion gases. This resistance to carbon monoxide makes insulating fire bricks an ideal choice for applications such as furnaces, kilns, and other high-temperature environments where the risk of carbon monoxide exposure is present.

- Q: Can insulating fire bricks be used in the construction of lime production linings?

- Yes, insulating fire bricks can be used in the construction of lime production linings. These bricks are designed to withstand high temperatures and provide insulation, making them suitable for lining furnaces and kilns used in lime production. They can help maintain the desired temperature, conserve energy, and improve the efficiency of the lime production process.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 5 Million |

| Main Markets | 10.00% Northern Europe 30.00% North America 30.00% Eastern Asia 5.00% Africa 10.00% Southeast Asia 15.00% Western Europe |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 10 |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 16,000 square meters |

| No. of Production Lines | Above 3 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Insulating Fire Brick - GJM32

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000 pcs pc

- Supply Capability:

- 1000 Tons Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords