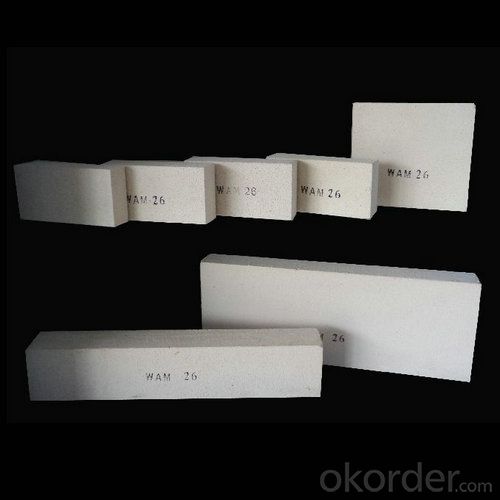

High Purity Alumina Clay Insulating Fire Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Insulating Firebricks

CMAX Insulating Firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Features of Insulating Firebricks

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Applications of Insulating Firebricks

CMAX Insulating Firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

Specifications of Insulating Firebricks

°C Classification Temperature °F | 1260 2300 | 1350 2500 | 1430 2600 | 1540 2600 | 1650 3000 | 1760 3200 | |

ASTM C134-95 g/cm³ Bulk Density ib/ft³ | 0.60 37 | 0.80 50 | 0.80 50 | 0.90 56 | 1.03 64 | 1.25 78 | |

ASTM C133-97 Mpa Cold Crushing Strength ib/in² | 1.2 170 | 2.0 284 | 2.0 284 | 2.6 370 | 2.8 398 | 3.4 484 | |

ASTM C133-97 Mpa Modulus of rupture ib/in² | 0.9 128 | 1.2 170 | 1.5 218 | 1.6 232 | 1.7 247 | 2.0 290 | |

ASTM C210-95 % Permanent Liner Change °C*hrs | 0 1230*24 | -0.5 1350*24 | -0.5 1400*24 | -0.8 1510*24 | -0.9 1620*24 | -0.9 1730*24 | |

ASTM C182-88 Thermal Conductivity (W/m.k) | 400°C | 0.17 | 0.24 | 0.24 | 0.30 | 0.40 | 0.49 |

600°C | 0.19 | 0.28 | 0.27 | 0.32 | 0.42 | 0.50 | |

800°C | 0.22 | 0.32 | 0.30 | 0.35 | 0.44 | 0.51 | |

1000°C | 0.25 | 0.37 | 0.32 | 0.38 | 0.45 | 0.53 | |

1200°C | --- | --- | 0.35 | 0.39 | 0.47 | 0.55 | |

Chemical Analysis of Insulating Firebricks | |||||||

Al2O3 % | 45 | 50 | 55 | 65 | 72 | 76 | |

Fe2O3 % | 0.9 | 0.8 | 0.8 | 0.5 | 0.4 | 0.3 | |

SiO2 % | 50 | 45 | 42 | 32 | 26 | 22 | |

CaO+MgO % | 0.7 | 0.6 | 0.3 | 0.2 | 0.3 | 0.2 | |

K2O+Na2O % | 1.3 | 1.0 | 1.0 | 0.8 | 0.2 | 0.1 | |

Images of Insulating Firebricks

FAQ of Insulating Firebricks

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a general idea of the specification and technical data of your products?

CNBM offer a range of refractory and insulation products. We provide refractory bricks, monolithic refractories as well as ceramic fiber products. And On your given shapes, drawings or description, we are producing refractories with all sizes and shapes, resistant to temperature from 800 °C till 1800 °C, using various machines and equipments for cutting, grinding, drilling, polishing, shaping processes.

Every refractory product by CNBM is of superior quality. Lesser refractory products can not approach. CNBM utilizes proprietary testing methods, testing for chemical content, density, apparent porosity, cold crush strength and modulus of rapture. With stringent quality control, you can count on CNBM products to exceed refractory industry standards and your expectations.

3. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

4. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q: What are the different types of insulating fire bricks available?

- There are several different types of insulating fire bricks available, each with their own unique characteristics and applications. Some of the most common types include: 1. Lightweight Insulating Fire Bricks (IFBs): These bricks are made from lightweight materials, such as expanded clay, perlite, or vermiculite, which are blended with a binder to form a porous structure. They have excellent insulation properties and are commonly used in applications where high temperatures need to be maintained, such as in kilns or furnaces. 2. Mullite Insulating Fire Bricks: Mullite bricks are made from a combination of alumina and silica, resulting in a high-temperature resistant material. These bricks have excellent thermal shock resistance and are often used in applications where rapid heating and cooling cycles are involved, such as in glass manufacturing or incinerators. 3. Alumina Insulating Fire Bricks: As the name suggests, these bricks are made primarily from alumina, a high-temperature resistant material. They have excellent thermal conductivity and are often used in applications where high temperatures need to be maintained, such as in the iron and steel industry or in the production of ceramics. 4. Silica Insulating Fire Bricks: Silica bricks are made primarily from silica, a heat-resistant material. They have excellent thermal insulation properties and are often used in applications where high temperatures need to be maintained, such as in the construction of kilns or furnaces. 5. Calcium Silicate Insulating Fire Bricks: These bricks are made from a combination of calcium silicate and other insulating materials. They have excellent thermal insulation properties and are often used in applications where high temperatures need to be maintained, such as in the petrochemical industry or in power plants. Overall, the choice of insulating fire brick depends on the specific requirements of the application, including temperature resistance, thermal conductivity, and thermal shock resistance. It is important to select the appropriate type of insulating fire brick to ensure optimal performance and safety.

- Q: Can insulating fire bricks be used in high-temperature insulation panels?

- Yes, insulating fire bricks can be used in high-temperature insulation panels. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation. They are made from lightweight refractory materials that have low thermal conductivity, allowing them to effectively reduce heat transfer. These bricks can be used in various applications, including furnaces, kilns, and high-temperature insulation panels. They are capable of withstanding temperatures up to 3000°F (1650°C) and can effectively retain heat, making them an ideal choice for high-temperature insulation panels.

- Q: Are insulating fire bricks porous?

- Yes, insulating fire bricks are porous. Porosity is a characteristic of insulating fire bricks that allows them to have low thermal conductivity. These bricks are made from ceramic materials and contain a high percentage of tiny air pockets or voids, which trap and slow down the transfer of heat. This porosity also makes the bricks lightweight and resistant to thermal shock. The ability of the insulating fire bricks to retain heat and provide effective insulation is directly linked to their porous structure.

- Q: Are insulating fire bricks suitable for insulation in boilers for steam generation?

- Yes, insulating fire bricks are suitable for insulation in boilers for steam generation. Insulating fire bricks are specifically designed to have excellent thermal insulation properties, which make them ideal for use in high-temperature applications such as boilers. These bricks have a low thermal conductivity, meaning they can effectively reduce heat transfer and prevent heat loss. This insulation capability helps to maintain high temperatures within the boiler, improving energy efficiency and reducing fuel consumption. Additionally, insulating fire bricks are resistant to thermal shock, which is crucial for withstanding the extreme temperature fluctuations that occur in steam generation. Overall, using insulating fire bricks in boilers for steam generation can enhance the thermal efficiency and performance of the system.

- Q: Can insulating fire bricks be used in the construction of hot air generators?

- Indeed, the utilization of insulating fire bricks is applicable in the fabrication of hot air generators. Specifically engineered to endure extreme temperatures and deliver exceptional thermal insulation, insulating fire bricks are well-suited for incorporation into hot air generators. These generators necessitate insulation to uphold elevated temperatures and avert heat dissipation. By diminishing heat transfer to the surroundings, insulating fire bricks effectively enhance the efficiency and functionality of hot air generators. Furthermore, their lightweight nature, effortless installation, and long-lasting durability contribute to their widespread adoption in diverse industrial sectors, including the construction of hot air generators.

- Q: Are there any differences between insulating bricks and refractory bricks?

- The insulation performance of thermal conductivity of insulating brick in general 0.2-0.4 (average temperature 350 - 25 DEG C) w/m.k, and the thermal conductivity of refractory brick in 1 (the average temperature of 350 - 25 DEG C) above w/m.k, which can obtain the insulation performance of insulating brick than refractory brick insulation performance is much better.

- Q: Do insulating fire bricks have a high electrical resistivity?

- Yes, insulating fire bricks generally have a high electrical resistivity. This is because these bricks are specifically designed to have low thermal conductivity and high thermal resistance, which also translates into high electrical resistivity. The insulating materials used in these bricks, such as alumina, silica, and other refractory materials, have inherently high electrical resistivity. Additionally, the manufacturing processes often involve the addition of insulating additives, further enhancing the electrical resistivity of the fire bricks. As a result, insulating fire bricks are effective in reducing heat transfer and maintaining high temperatures in various industrial applications, such as kilns, furnaces, and thermal insulation systems.

- Q: Can insulating fire bricks be used in chimneys or flue systems?

- Yes, insulating fire bricks can be used in chimneys or flue systems. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation. Their ability to resist heat makes them suitable for lining chimneys and flue systems, helping to reduce heat loss and improve overall efficiency.

- Q: Are insulating fire bricks suitable for insulation in cryogenic applications?

- Yes, insulating fire bricks are suitable for insulation in cryogenic applications. Insulating fire bricks have excellent thermal insulation properties, low thermal conductivity, and can withstand extremely low temperatures. This makes them ideal for use in cryogenic applications where insulation is required to maintain the low temperature of the system.

- Q: Do insulating fire bricks require any special cleaning procedures?

- Special cleaning procedures are not necessarily needed for insulating fire bricks. Nevertheless, just like any other substance, they can gather dust, dirt, or debris as time goes on, which may diminish their insulating capabilities. To uphold their effectiveness, it is suggested to occasionally eliminate any loose particles by gently brushing or vacuuming the surface of the bricks. If the bricks come into contact with oil or grease, it is recommended to utilize a mild detergent or soap solution for cleansing the affected regions. In general, consistent maintenance and preventing excessive accumulation will guarantee their optimal performance.

Send your message to us

High Purity Alumina Clay Insulating Fire Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords