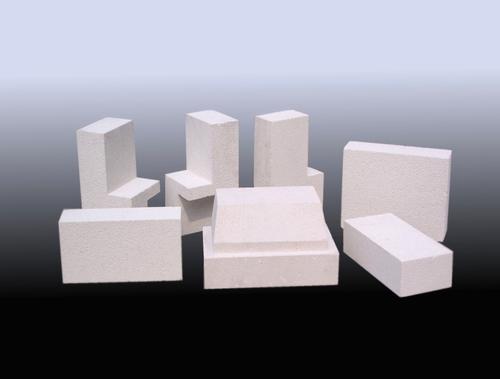

Insulating Fire Brick GJM28 - High Performance Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application

CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass.

- Q: Are insulating fire bricks resistant to thermal fatigue?

- Insulating fire bricks exhibit remarkable resistance to thermal fatigue. These bricks are purposefully engineered to endure elevated temperatures and thermal cycling without experiencing any cracks or fractures. Composed of refractory materials with exceptional thermal shock resistance, they possess the ability to expand and contract without suffering significant harm. This capacity to withstand thermal fatigue renders insulating fire bricks highly suitable for applications involving extreme temperature fluctuations, such as kilns, furnaces, and other environments with high temperatures.

- Q: Are insulating fire bricks resistant to erosion?

- Yes, insulating fire bricks are generally resistant to erosion. Insulating fire bricks are made of lightweight materials such as alumina, silica, or a combination of both. These materials have excellent resistance to erosion caused by high temperatures, chemical reactions, and physical wear. They are designed to withstand extreme heat and harsh conditions, making them highly durable against erosion. Additionally, insulating fire bricks have low thermal conductivity, which means that they do not absorb or transfer heat easily, further protecting them from erosion. However, it is important to note that the resistance to erosion may vary depending on the specific composition and quality of the insulating fire bricks.

- Q: Can insulating fire bricks be used in the construction of tundishes?

- Yes, insulating fire bricks can be used in the construction of tundishes. Tundishes are commonly used in the steel industry to distribute molten metal, and insulating fire bricks are ideal for this purpose as they have excellent thermal insulation properties and can withstand high temperatures.

- Q: What is the price of concrete self insulation bricks?

- Insulation brick prices also have a great relationship with the material and workmanship, such as clay brick price is much lower than high alumina brick, mullite and corundum brick prices will be higher.

- Q: Can insulating fire bricks be used in cement plants?

- Certainly, cement plants can utilize insulating fire bricks. These bricks are specifically engineered to endure extreme temperatures and are widely employed in thermal insulation-demanding industries. Within cement plants, they can find diverse applications, including kiln lining, furnace lining, and other equipment operating at high temperatures. These bricks effectively decrease heat dissipation, enhance energy efficiency, and maintain stable and regulated temperatures during cement production. Furthermore, insulating fire bricks possess a lightweight nature and exhibit low thermal conductivity, rendering them an optimal selection for insulation purposes within cement plants.

- Q: Can insulating fire bricks be used in heat treatment furnaces?

- Yes, insulating fire bricks can be used in heat treatment furnaces. Insulating fire bricks are specially designed to have low thermal conductivity, which means they are able to withstand high temperatures while minimizing heat loss. This makes them ideal for use in heat treatment furnaces, where maintaining a consistent temperature is crucial for the successful heat treatment process. Additionally, insulating fire bricks have excellent insulating properties, which helps to reduce energy consumption and improve the overall efficiency of the heat treatment furnace. Therefore, using insulating fire bricks in heat treatment furnaces is a common practice in various industries.

- Q: How do insulating fire bricks affect the overall carbon footprint of a structure?

- Insulating fire bricks can significantly reduce the carbon footprint of a structure. These bricks have higher thermal insulation properties compared to traditional bricks, which means they can better retain heat and reduce the need for excessive heating or cooling. By improving energy efficiency and reducing the consumption of fossil fuels, insulating fire bricks help to lower the carbon emissions associated with the structure's operation. Additionally, their longer lifespan and recyclability contribute to further environmental benefits by reducing waste generation and the need for frequent replacements, ultimately minimizing the overall carbon footprint of the structure.

- Q: Can insulating fire bricks be used in the construction of lime kilns?

- Yes, insulating fire bricks can be used in the construction of lime kilns. These bricks are specially designed to withstand high temperatures and provide excellent insulation, making them suitable for lining the interior of lime kilns. Their ability to retain heat and reduce heat loss can help enhance the efficiency and performance of the lime kiln.

- Q: Are insulating fire bricks resistant to freeze-thaw cycles?

- Yes, insulating fire bricks are generally resistant to freeze-thaw cycles. These bricks are designed to have low thermal conductivity and high resistance to thermal shock, which makes them highly durable and capable of withstanding extreme temperature variations, including freeze-thaw cycles. This resistance to freeze-thaw cycles is crucial in applications where the bricks are exposed to fluctuating temperatures, such as in furnaces, kilns, and other high-temperature environments. The insulating properties of these bricks also help to minimize heat loss and prevent moisture penetration, further enhancing their resistance to freeze-thaw cycles. However, it is important to note that the specific composition and manufacturing process of the insulating fire bricks can vary, so it is always recommended to consult the manufacturer's specifications and guidelines to ensure the bricks are suitable for the intended application.

- Q: Are insulating fire bricks resistant to carbon monoxide?

- Yes, insulating fire bricks are resistant to carbon monoxide.

Send your message to us

Insulating Fire Brick GJM28 - High Performance Insulation

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords