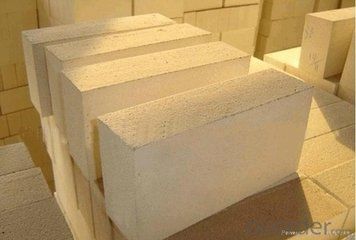

High Quality Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal insulation brick is introduced

A, fully replace aluminous model board, honeycomb panel, curtain wall, such as common decoration materials, multi-functional integration, a construction can solve the heat preservation decoration two functional requirements,

level off is smooth and beautiful adornment sex is strong.

2, high strength, good rigidity, light seismic and wind resistance, creep, superior performance,

reduce building load and more economic and durable.

Three fire retardant, heat preservation and heat insulation, sound insulation, heat insulation, anti-cracking waterproof, according to 65% of building energy efficiency requirements for construction design.

Four Jin Anhua, easy installation and finishing products, process, shorten the construction period and quality easy to control.

Five, don't use aluminum, steel, keel support, set in the installation, reduce the gap between the insulation

board and wall body.Increased security system.

Six, no radiation, green environmental protection, can be widely used in all kinds of public buildings and home interior decoration.

Seven, installed with cement, save a lot of material, manpower and time.Reduce the air pollution caused by

production cement burning, accord with the requirement of green low carbon environmental protection.

Eight, more than 70 carrier lifetime, more than 20 years of decoration life for a long time, to adapt to a variety

of areas such as zha climate and complex environment.With the quality of class international aluminous model board,

aluminum veneer and steel hanging stone, compared to reduce bearing 30% to 90%

Nine, double efficacy, shorten time li

- Q: The project cost in hydropower No.3 shaft wall is solid brick or insulating brick?

- Aerated concrete for external walls is to save money. One side is the outer wall.. Solid bricks are the first thing, safety comes first.

- Q: Can insulating fire bricks be used in chimney construction?

- Indeed, insulating fire bricks have the capability to be utilized in the construction of chimneys. These bricks are specifically designed to possess a low thermal conductivity, which ultimately leads to their effectiveness in minimizing heat transfer. As a result, they prove themselves suitable for chimney construction as they aid in maintaining cooler chimney walls and preventing excessive heat from being transmitted to the surrounding structures. Moreover, apart from their lightweight nature, insulating fire bricks possess commendable insulation properties, thereby making their handling and installation in chimney construction a much simpler task. However, it is imperative to acknowledge that in order to comply with safety regulations and ensure proper chimney construction, it is crucial to utilize insulating fire bricks in conjunction with other fire-resistant materials.

- Q: What materials are used to make insulating fire bricks?

- Insulating fire bricks are made from a variety of materials that possess high thermal insulation properties. The most common material used in the production of these bricks is a type of clay known as kaolin clay. This clay is mixed with other additives such as alumina, silica, and zirconium to enhance its insulating properties and increase its resistance to high temperatures. In addition to clay, other materials like sawdust, vermiculite, perlite, and calcium silicate are also sometimes added to the mixture to further improve the insulation capabilities of the bricks. Overall, the combination of these materials allows insulating fire bricks to have low thermal conductivity, high heat resistance, and excellent insulation qualities, making them suitable for a wide range of industrial and domestic applications.

- Q: Can insulating fire bricks be used in the construction of refractory linings?

- Yes, insulating fire bricks can be used in the construction of refractory linings. Insulating fire bricks are specifically designed to have excellent thermal insulation properties, making them ideal for applications where high temperatures need to be contained. They are commonly used in the construction of furnaces, kilns, and other high-temperature environments. The insulating properties of these bricks help to reduce heat loss, improve energy efficiency, and maintain a stable temperature within the refractory lining. Additionally, insulating fire bricks are lightweight and easy to handle, making them a practical choice for refractory lining construction.

- Q: Can insulating fire bricks be used as a heat shield?

- Yes, insulating fire bricks can be used as a heat shield. Insulating fire bricks are designed to have excellent thermal insulation properties, which means that they can effectively block and reflect heat. They are commonly used in applications where heat needs to be contained or redirected, such as in fireplaces, kilns, furnaces, and industrial ovens. The insulating properties of these bricks allow them to reduce heat transfer, providing a barrier between the intense heat source and the surrounding environment. Additionally, they have high melting points and can withstand high temperatures, making them suitable for use as a heat shield. However, it is important to note that the effectiveness of insulating fire bricks as a heat shield may vary depending on the specific requirements and conditions of the application.

- Q: Can insulating fire bricks be used in the construction of ceramic fiber-lined kilns?

- Yes, insulating fire bricks can be used in the construction of ceramic fiber-lined kilns. Insulating fire bricks are designed to provide excellent insulation and can help increase the energy efficiency of the kiln. By using insulating fire bricks, the kiln can reach and maintain higher temperatures while minimizing heat loss through the walls.

- Q: How does an insulating fire brick work?

- Insulating fire bricks, which are also referred to as refractory bricks, serve as thermal barriers in various industrial applications and are designed to withstand high temperatures. These bricks are made from refractory materials that possess low thermal conductivity, indicating their poor heat conduction abilities. The primary mechanism employed by insulating fire bricks revolves around their capability to hinder and slow down heat transfer. Unlike regular bricks or concrete, insulating fire bricks possess a significant number of air pockets within their structure, which act as insulators. These air pockets effectively obstruct the movement of thermal energy, preventing heat transfer. When exposed to high temperatures, insulating fire bricks absorb minimal amounts of heat due to their low thermal conductivity. Rather than conducting heat through the brick, the energy is either absorbed or reflected by the air pockets present in the brick's structure. As a result, heat is unable to permeate to the other side of the brick, effectively creating a thermal barrier. Moreover, the refractory materials utilized in insulating fire bricks inherently possess resistance against thermal shock, enabling them to endure rapid temperature changes without cracking or breaking. This quality makes them exceptionally suitable for applications where extreme temperature fluctuations occur frequently. Insulating fire bricks find extensive usage in industries such as metallurgy, ceramics, glass manufacturing, and kiln construction. They are primarily used to line furnaces, kilns, and other equipment operating at high temperatures. By effectively reducing heat transfer, these bricks contribute to enhancing energy efficiency, minimizing heat loss, and safeguarding surrounding materials and structures from the extreme levels of heat. In summary, the operational principle of an insulating fire brick lies in its ability to minimize heat transfer by virtue of its low thermal conductivity and air pocket structure. By establishing a thermal barrier, these bricks fulfill a critical role in providing insulation, protecting against heat loss, and ensuring the smooth functioning of high-temperature processes.

- Q: Can insulating fire bricks be used in incinerators?

- Yes, insulating fire bricks can be used in incinerators. Insulating fire bricks are specially designed to provide excellent thermal insulation, making them ideal for applications where high temperatures need to be maintained. In incinerators, which operate at extremely high temperatures, insulating fire bricks can help to reduce heat loss and improve the overall energy efficiency of the system. Additionally, these bricks have good resistance to thermal shock, which is crucial in incinerators where rapid temperature changes occur. Therefore, using insulating fire bricks in incinerators can help to enhance their performance and longevity.

- Q: Do insulating fire bricks have a high resistance to creep?

- Yes, insulating fire bricks generally have a high resistance to creep. The low thermal conductivity and high refractoriness of these bricks allow them to withstand high temperatures without significant deformation or creep.

- Q: Can insulating fire bricks be used for insulation in petrochemical plants?

- Yes, insulating fire bricks can be used for insulation in petrochemical plants. Insulating fire bricks have high thermal resistance and can withstand high temperatures, making them suitable for insulation in petrochemical plants where heat containment is crucial.

Send your message to us

High Quality Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords