Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

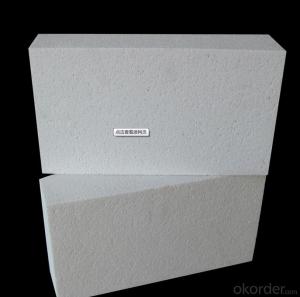

mullite insulation brick

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-5

Light weight mullite insulation furnace bricks refractory for sale

Advantage

Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy savingRefractory GJM Mullite Insulation Brick B-5

Description:

Lightweight mullite kiln bricks refractory for sale are made from good quality and superpure raw materials, with strictly classified fillings according to their grades. These fillings can form a uniform pore structure after burnt during the process of manufacture. Each grade of products has unique design to meet different thermal, physical and chomical demands.

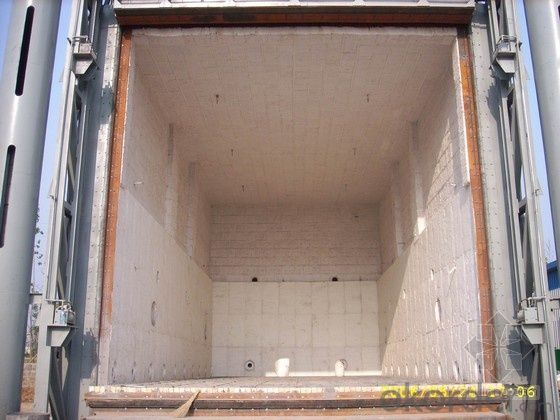

Application:Refractory GJM Mullite Insulation Brick B-5

Mullite insulation furnace bricks refractory material can be used in linings or heat-insulating materials of the industries, such as, ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etcRefractory GJM Mullite Insulation Brick B-5

Mullite Insulation furnace refractory material can be used as working lining, where contact with flames directly. This kind of brick can save the kiln energy very muchRefractory GJM Mullite Insulation Brick B-5

- Q: Can insulating fire bricks be used in the construction of pizza ovens?

- Yes, insulating fire bricks can be used in the construction of pizza ovens. These bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for use in pizza ovens. They can help retain heat efficiently, resulting in a more even and consistent cooking temperature. Insulating fire bricks also have low thermal conductivity, which means they prevent heat loss and ensure the pizza oven remains hot for longer periods, enhancing energy efficiency. Overall, using insulating fire bricks in the construction of pizza ovens can contribute to better heat retention, improved cooking performance, and more energy-efficient operation.

- Q: Is it necessary to use mortar when installing insulating fire bricks?

- Yes, it is necessary to use mortar when installing insulating fire bricks. Mortar acts as a bonding agent between the bricks, ensuring stability and preventing heat loss. It also helps to seal any gaps or cracks, enhancing the insulation properties of the bricks.

- Q: Do insulating fire bricks require regular maintenance?

- Insulating fire bricks do not require regular maintenance as they are designed to withstand high temperatures and resist wear and tear. They are made from materials that are highly durable and have excellent insulation properties. However, it is important to periodically inspect them for any cracks, chips, or signs of damage. If any damage is found, it should be repaired promptly to ensure the bricks continue to function optimally. Additionally, regular cleaning of the bricks can help remove any build-up of debris or residue, which can affect their insulating properties. Overall, while insulating fire bricks do not require frequent maintenance, regular inspections and occasional cleaning are recommended to ensure their longevity and performance.

- Q: Are insulating fire bricks resistant to acids?

- Insulating fire bricks, known as refractory bricks as well, exhibit a general resistance towards acids. They are crafted from materials that can withstand high temperatures, namely silica, alumina, and other refractory oxides, which grant exceptional resistance against chemical attacks. Nevertheless, it must be emphasized that the degree of acid resistance may differ based on the precise composition and manufacturing technique employed in the production of these insulating fire bricks. It is advisable to seek guidance from the manufacturer or supplier to acquire comprehensive information regarding the acid resistance of the specific variant of insulating fire bricks being utilized.

- Q: Can insulating fire bricks be used in the construction of heat shields?

- Yes, insulating fire bricks can be used in the construction of heat shields. Insulating fire bricks are specially designed to handle high temperatures and provide excellent thermal insulation. They can effectively absorb and distribute heat, making them ideal for creating heat shields that protect against intense heat and prevent it from reaching sensitive areas or materials.

- Q: Do insulating fire bricks require special handling?

- Yes, insulating fire bricks do require special handling. These bricks are made from lightweight refractory materials and are designed to withstand high temperatures. Due to their fragile nature, they should be handled with care to prevent breakage or damage. It is recommended to use proper lifting and carrying techniques, such as wearing gloves and using tongs or lifters, to avoid accidents or injuries. Additionally, insulating fire bricks should be stored in a dry and protected area to prevent moisture absorption, which can affect their thermal properties.

- Q: Are insulating fire bricks chemically resistant?

- Yes, insulating fire bricks are chemically resistant. They are composed of high-temperature materials that can withstand harsh chemical environments without undergoing significant chemical reactions or degradation. This resistance makes them suitable for various industrial applications where exposure to chemicals is a concern.

- Q: There are several construction techniques for exterior wall insulation

- Exterior wall insulationSingle material thermal insulation exterior wall: aerated concrete and sintered insulating brickComposite insulation exterior wall: according to the different settings of thermal insulation materials, it can be divided into internal insulation, external insulation and sandwich insulation exterior wall. Thermal insulation decorative integrated board.Other: insulation blocks, etc.

- Q: Are insulating fire bricks resistant to acids and alkalis?

- Insulating fire bricks are generally resistant to acids and alkalis, but the level of resistance can vary depending on the specific composition and manufacturing process of the bricks. Insulating fire bricks are typically made from materials such as alumina, silica, or a combination of both, which provide excellent resistance to high temperatures and thermal conductivity. These materials are generally chemically inert, meaning they do not react with acids or alkalis. However, it is important to note that some acids and alkalis can still cause slight degradation or corrosion over time, especially if they are highly concentrated or used at elevated temperatures. In such cases, it is advisable to consult the manufacturer's specifications or conduct specific tests to determine the level of resistance of the insulating fire bricks to the particular acids or alkalis in question. Overall, insulating fire bricks are a suitable choice for applications that involve exposure to acids and alkalis, but it is always recommended to consider the specific requirements and consult with experts or manufacturers to ensure the bricks will perform adequately in the intended environment.

- Q: Can insulating fire bricks be used in chimney construction?

- Indeed, insulating fire bricks have the capability to be utilized in the construction of chimneys. These bricks are specifically designed to possess a low thermal conductivity, which ultimately leads to their effectiveness in minimizing heat transfer. As a result, they prove themselves suitable for chimney construction as they aid in maintaining cooler chimney walls and preventing excessive heat from being transmitted to the surrounding structures. Moreover, apart from their lightweight nature, insulating fire bricks possess commendable insulation properties, thereby making their handling and installation in chimney construction a much simpler task. However, it is imperative to acknowledge that in order to comply with safety regulations and ensure proper chimney construction, it is crucial to utilize insulating fire bricks in conjunction with other fire-resistant materials.

Send your message to us

Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords