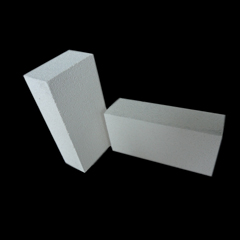

High Quality Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

CMAX insulating firebricks are classified under temperature

between 1100℃ to 1700℃, manufactured from high purity alumina

clay.

Quick Details

| Place of Origin: | Shape: | Material: | |||

| Model Number: | Brand Name: | brick: |

Packaging & Delivery

| Packaging Detail: | wooden pallet |

| Delivery Detail: | in 30 days |

Specifications

1.NG series clay insulation brick

2.Bulk Density:0.6,0.7,0.8,0.9,1.0

4.STD size:230 x 114 x65 mm

Product Index | NG-1.0 | NG-0.9 | NG-0.8 | NG-0.7 | NG-0.6 |

Bulk density g/cm3 | ≤1.0 | ≤0.9 | ≤0.8 | ≤0.7 | ≤0.6 |

Cold crushing strength kg/cm2 | ≥35 | ≥25 | ≥25 | ≥25 | ≥20 |

Permanent linear change temp. | ≥1350 | ≥1300 | ≥1250 | ≥1250 | ≥1200 |

Thermal conductivity 350oC±25 W/m·k | ≤0.5 | ≤0.4 | ≤0.35 | ≤0.35 | ≤0.25 |

- Q: Are insulating fire bricks safe to use?

- Yes, insulating fire bricks are safe to use. They are specifically designed to withstand high temperatures and are made from non-toxic materials that do not emit harmful gases or substances when heated. They provide excellent insulation and are commonly used in various applications such as kilns, furnaces, and fireplaces.

- Q: Can insulating fire bricks be used in the construction of pizza ovens?

- Yes, insulating fire bricks can be used in the construction of pizza ovens. These bricks have excellent heat retention properties which help to create a high and even temperature inside the oven. Additionally, their insulating properties help to decrease heat loss, making them ideal for pizza ovens where maintaining a consistent and high temperature is crucial for achieving crispy and delicious pizzas.

- Q: Are insulating fire bricks resistant to thermal shock cracking?

- Yes, insulating fire bricks are resistant to thermal shock cracking. These bricks are specifically designed to withstand high temperatures and rapid changes in temperature without cracking. They have a low thermal conductivity, which means they can effectively trap and retain heat without being damaged by thermal shock. Insulating fire bricks are often used in applications where thermal shock is a concern, such as in furnaces, kilns, and other high-temperature environments. Their resistance to thermal shock cracking makes them a reliable choice for these types of applications.

- Q: Are insulating fire bricks resistant to water penetration?

- Yes, insulating fire bricks are resistant to water penetration. These bricks are designed to have a low porosity and are made from materials that are not prone to absorbing or retaining water. They are typically composed of lightweight refractory materials such as alumina, silica, and other minerals that have high heat resistance and low water absorption properties. This makes insulating fire bricks ideal for applications where water penetration could be detrimental, such as in high-temperature environments or when used as insulation in chimneys or kilns. However, it is important to note that while these bricks are resistant to water penetration, they are not completely impervious to it. Prolonged exposure to water may eventually lead to some level of water absorption, which can affect their insulating properties. Therefore, it is advisable to take precautions and ensure proper installation and maintenance to maximize their resistance to water penetration.

- Q: Can insulating fire bricks be used as a lining for chimneys?

- Yes, insulating fire bricks can be used as a lining for chimneys. These bricks are designed to withstand high temperatures and provide insulation, making them suitable for lining chimneys and protecting them from heat damage.

- Q: How do insulating fire bricks perform in terms of thermal stability?

- Insulating fire bricks are known for their excellent thermal stability. They have a high resistance to thermal shock, meaning they can withstand rapid changes in temperature without cracking or breaking. Additionally, insulating fire bricks have low thermal conductivity, which allows them to effectively retain heat and provide insulation in high-temperature environments. Overall, their performance in terms of thermal stability is highly reliable.

- Q: Can insulating fire bricks be used in fireplace construction?

- Yes, insulating fire bricks can be used in fireplace construction. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for lining fireplaces. They help to retain heat and prevent the transfer of heat to the surrounding structure, thus increasing the efficiency of the fireplace and reducing the risk of damage to the surrounding materials. Additionally, insulating fire bricks are lightweight and easy to handle, making them ideal for fireplace construction.

- Q: Can insulating fire bricks be used in the construction of brick ovens?

- Yes, insulating fire bricks can be used in the construction of brick ovens. These bricks have high-temperature resistance and excellent insulation properties, making them suitable for retaining heat and preventing heat loss in a brick oven.

- Q: Are insulating fire bricks suitable for insulation in boilers?

- Yes, insulating fire bricks are suitable for insulation in boilers. Insulating fire bricks are made from lightweight materials such as clay and alumina, which have excellent insulating properties. They have a low thermal conductivity, meaning they are effective at preventing heat transfer and can help to significantly reduce heat loss in boilers. Additionally, insulating fire bricks are resistant to high temperatures, making them suitable for use in boilers where high heat is generated. They are also durable and can withstand the harsh conditions inside a boiler, including exposure to intense heat and corrosive gases. Overall, insulating fire bricks are a popular choice for boiler insulation due to their thermal efficiency and ability to withstand high temperatures.

- Q: Can insulating fire bricks be used in the construction of lime production linings?

- Yes, insulating fire bricks can be used in the construction of lime production linings. Insulating fire bricks are designed to have low thermal conductivity, which makes them excellent for applications where heat insulation is required. In lime production, high temperatures are required for the calcination process. Using insulating fire bricks in the construction of lime production linings helps to reduce heat loss and improve energy efficiency. Additionally, insulating fire bricks are lightweight and easy to handle, which makes them suitable for lining various parts of lime kilns and other equipment used in the lime production process. Overall, using insulating fire bricks in lime production linings can help to optimize the production process and improve the overall performance of lime production facilities.

Send your message to us

High Quality Insulating Fire Brick

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords