Plastic Zipper Injection Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set m.t.

- Supply Capability:

- 20 Sets Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery Of Plastic Zipper Injection Machine

Packaging Detail: | standard export wooden cases |

Delivery Detail: | 15 Days |

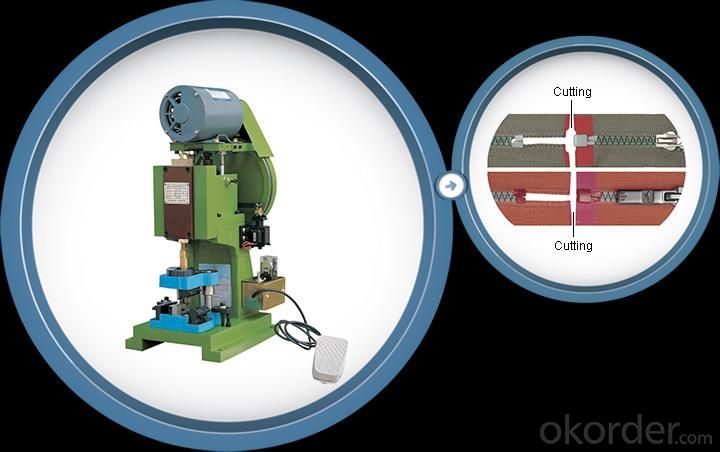

Specifications Of Plastic Zipper Injection Machine

1. Adpotscrew installation

2. Barrel lifted automatically

3. Plastic zipper injection machine

4. Adjustable conveying speed

Product Feature Of Plastic Zipper Injection MachineAdopt screw installation make the pigment melting & injecting quality evenly;

Once injection, top stop & bottom stop are made at the same time;

Auto-belt conveyor demands for less labor focre;

Hydraulic cylinders to pull strip liner in, barrel lifted automatically, humanized design and easily clean up;

User-friendly control system in English with full-scale functions;

Reliable proportional pressure valves ensures working safety;

Adjustable conveying speeds meets different requirement.

- Q: Injection molding machine products have cloak how to solve?

- Batch solution:1., mold clearance before and after too large, re matching die2., the mold is too thin, forming deformation; flow channel and inlet size is large3. molding pressure, speed is too fast, the material temperature / mold temperature is too high, too many melt adhesive, injection molding machine mold pressure is too small, machine tonnage is too small4. A: hand knife cut

- Q: 110 tons injection molding machine injection quantity is how many grams?

- This specific is too clear, you still go to ask the professionals in the field of injection molding machine

- Q: Injection machine profile size

- The aperture of the nozzle (injection hole) is generally 2.2-2.5mm.

- Q: What kinds of lubricants are used in the injection molding machine?

- Imported generally have thimble grease, the machine comes with lubricating oil bag

- Q: Production calculation... 60 / 60 seconds * / / 25 x 32 / sec / mold die =1 * 12 hours per hour yield = 12 small classInjection molding machine... Production calculation... 60 / 60 seconds * / / 25 / 32 / sec * die die =1 output * 12 hours = 12 hour shifts production 55075But I don't get enough output every day... Can only do 49501 pieces, ask 49501 pieces to take several hours to be able to do... How much extra time do I have to add to the production?... Urgent urgent... Can not take a day except what count how much time yield......

- 1. are you fully automated? If it's fully automated, then you'll be able to record each exception from minutes to minutes, so you know your abnormal hours. If it is semi-automatic production, it depends on the boot staff, the door is not stable, this can be seen inside the injection molding machine.

- Q: How to debug the injection molding machine? solve

- This is not to say the machine belongs to the high current working machine but also large machine should have a master in their own training proficient is best not to touch.

- Q: In the plastic injection molding machine barrel, why there are so many bubbles?

- There are two kinds of pores in the material. The first one contains moisture, and the raw material should be dried completely before processing, or at least 5% of the drier will be added during processing. The second is the material decomposition, to reduce the barrel temperature, reduce the melt pressure and speed, set the melt back pressure, but not too high; or adding appropriate amount of stabilizer in the raw material, it is not only a refueling.

- Q: What an elder brother knows how nitrogen injection is going on. What should I pay attention to?

- 1. the operator must undergo good safety education.2. operate strictly according to the operating rules of equipment.3., when the valve operation, wear protective equipment: masks, gloves, etc., to prevent frostbite.4. check the safety valve and pressure gauge once a year, check the riot film every two years, check and record the records.5. when the nitrogen emissions, people should stay away from the drain, otherwise, long time suffocate easily.6. in the obvious place to hang around the nitrogen tank "trespassers", "dangerous" and other warning signs.7. freezing on nitrogen pipe, no heavy blow.8. check the nitrogen tank every day and find the problem in time.9. always keep the nitrogen tank clean and free of oil and grease.10. equipment should be cut off for a long time without gas.

- Q: How to calculate the capacity of mold injection molding?

- For example, the first mock exam two points mold cycle for 15 seconds, then 12 hours of production capacity is 60 seconds /15 seconds = 4 mode 4X60=240 per minute per hour 240X12 hour = 2640

- Q: What are the injection molding machine brands in China?

- Can refer to modern plastic injection molding machine brand surveyIn recent years, the rapid development of China's plastics industry has greatly improved the injection molding machine industry. With Europe, the United States, Japan, Korea and many other internationally renowned injection molding machine brand access, as well as the rapid rise of China's injection molding machine enterprises, the market competition is becoming increasingly fierce. In order to help you understand the user China injection molding machine current demand psychology, demand status and dynamic demand, "PT" magazine on the basis of modern plastic Vogel industry media reader huge data resources at home and abroad, 54 injection molding machine brand, in the reader investigation activities brand demand. To improve the accuracy and objectivity of the survey, the survey issued a total of 3000 questionnaires, the main application areas covered by the injection molding machine, including packaging, automotive, household appliances, electronic communication equipment and medical equipment industries. A total of 355 valid questionnaires were received, of which more than 60% of respondents had equipment procurement decision-making rights or advice in the enterprise.

Send your message to us

Plastic Zipper Injection Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set m.t.

- Supply Capability:

- 20 Sets Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords