Injection molding machine LOG-320S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Condition: | New | Type: | Tube Head Injection | Style: | Horizontal |

| Brand Name: | LOG | Model Number: | LOG-320S8 | Place of Origin: | Zhejiang, China (Mainland) |

| Plastic Type: | Thermoplastic | Automatic: | Yes | Injection Weight: | 1120g |

| Injection Rate: | >362cm3/s |

| Clamping Force: | 3200KN | Opening Stroke: | 615mm | ||

| Power(W): | 31kw | Certification: | CE | After-sales Service Provided: | Engineers available to service machinery overseas |

| blue: | yellow |

Packaging & Delivery

| Packaging Details: | 20GP,40GP,40HQ |

| Delivery Detail: | 30 days |

Product Description

Product performance and advantages:

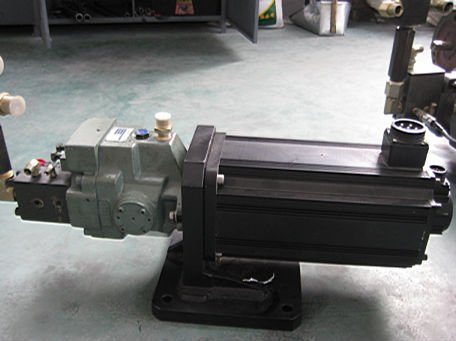

1. Servo energy-saving system

Using the servo motor oil electricity composite structure

2. Servo motor high response feature

It costs only 0.05s for servo energy saving injection molding machines to achieve the maximum output, in comparison with conventional hydraulic injection molding machines. The response speed has been obviously increased, improving the production efficiency.

3. Unique function

Large colored screen with TFT interface

Full automatic close-loop control

Module design of hardware

Auto-tune PID temperature control

Pc interface USB, PIC, and FLASH…

Curve monitoring and analysis function

K-can data transmission (500Kbit/s)

On-line central monitoring function

LOG-320S8 Technical parameters

Description | Unit | LOG-320S8 | ||

international recognized models | 1870/320 | |||

injection | A | B | C | |

Tjeoretical injection volume | cm³ | 1062 | 1231 | 1414 |

Shot volume | g | 966 | 1120 | 1286 |

Oz | 33.7 | 39.2 | 44.9 | |

Screw diameter | mm | 65 | 70 | 75 |

Injection diameter | mpa | 175 | 152 | 133 |

Screw L:D ratio | 22.6:1 | 21:1 | 19.6:1 | |

Scerw steoke | mm | 320 | ||

Screw rotate speed | r/min | 0-150 | ||

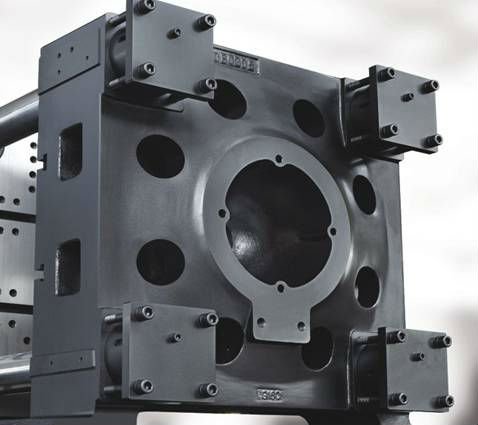

CLAMPING UNIT | ||||

Clamping force | kN | 3200 | ||

Opening stroke | mm | 615 | ||

Platen size | mm*mm | 945*945 | ||

Space between tie bars | mm*mm | 660*660 | ||

Maldthickness | mm | 250-670 | ||

Platen Mix stroke | mm | 1285 | ||

Ejection stroke | mm | 160 | ||

Ejcetion force | kN | 77 | ||

Power/Elcetric Heating | ||||

Hydralic system pressure | Mpa | 17.5 | ||

Pump motor | kw | 31 | ||

Heating power | kw | 25.3 | ||

Number of temp.conteol | 5+nozzle | |||

Other | ||||

Cycle time | sec | 5.0 | ||

Tank volume | L | 500 | ||

Machine dimesions | m*m*m | 6.8*1.63*2.25 | ||

Weight of machine | kg | 13000 | ||

- Q: How do you increase your product? How do you assign multiple segments? Speed? How to determine the holding position? Big, good or small? All help answer! Be deeply grateful!

- The distribution of each position and velocity, if familiar with the products of the case, according to the previously adjusted product size, short range, reducing the pressure and speed, the adjusted number of a few know it, and then slowly add pressure and velocity, and material. Process debugging did not say big products, good tune or small products good tune, this with your craft level, material, mold, equipment and so on have the factor.

- Q: How many moulds can the 80 ton injection molding machine put down?

- There are two main decisions: meaning opening distance, and two is the distance between the guide pillars.

- Q: Can polyurethane (PU) material be molded by injection molding machine?

- PU according to the hardness can be divided into a variety of, can be injection molding, molding temperature between 170-210. Shoes materials, wheels are used more

- Q: when the temperature rising in the exit but this is what the normal temperature increase of more than 20 degrees

- PVC for the temperature requirements are very strict, the back pressure is small, hard PVC temperature can not too low at about 170-190, too low, but not good, there is a delay melt, namely the screw does not move after injection, on the verge of opening a few seconds before time began to melt, melt after 10 seconds to stop the opening of concrete how much time delay according to the time you began to melt cooling and temperature control, there is a nozzle to just not cured so far, should not be too high. This basically can control the temperature, can be controlled within 8 degrees.

- Q: The first paragraph of the injection molding machine does not rise in temperature. What's the matter?

- The heating ring is badShort circuit burnoutAC contactor damageThe fuse tube is burnt outChasing the answerSwitch trip6: temperature line connection error or damage

- Q: I want to know something about the purchase of high-end injection molding machinesCustomers in the whole power and hydraulic injection molding machine purchase process, those machine advantages, they are more concerned about, and if you choose to buy, then you will choose all electric or full hydraulic machine, why? To know a friend told me, we discuss together, thanked the boy in this

- All electric injection molding machine, injection molding machine Dongyang (TOYO), Sadegh (Sodick), FANUC injection molding machine injection molding machine (Fanuc)Day steel injection molding machine (JSW), Ke Chun injection molding machine (KeJun), two-color injection molding machine.

- Q: What's the meaning of "loosening and retreating" before injection machine?

- In the gum before the action, do plastic pumping action, that is, before the release of pine, in the volume of gum after doing loose retreat, that is, after the pine back, which is more commonly used

- Q: transparent parts inside the bubble, how to solve this problem, non -, what is the cause?

- First of all, we should first analyze where this gas comes from, and how to prevent and reduce the generation of gas.First, when the particles melt in the screw, it will produce smoke. Second, the mold cavity itself contains air, at the time of injection if the air line out will be wrapped into the material to. Third, the moisture in the material produces water vapor at high temperature. (do not think that the drying temperature and time are enough, it must be dry, and wet weather will not be dried by ordinary dryers)From these three directions to improve, first, reduce the material temperature (reduce the production of smoke). Two, slow down the injection rate (which is good for the exhaust gas). Three increase mold temperature (improve material flow due to lower material speed). Four, fully guarantee the drying of materials (PC and PA66 moisture content must be less than 0.03%). Five, the mold into the glue point to enlarge (conducive to the actual effect of packing). Six, the increase in back pressure (effectively increase the density of the material). Seven, the mold exhaust should be guaranteed.From the above points by item examination and improvement, the problem will certainly be solved.In addition, just look at the picture, playing this bubble, the process must be a problem.

- Q: How does the injection machine set up the die segments and the pressure and speed of each segment? Seek advice.

- Simple injection molding closed mold process is divided into start - Fast - low pressure - high pressure four processes,Among them, the starting speed should be low speed and low voltage (usually 30% or less 40bar), the distance is about 5-10mm, and then enter the fast closed die process.Medium speed (40%-60%) and medium pressure (30-50bar) should be used in fast closed die. The distance is longer, the distance begins at low voltage protection, and the position is not finished.

Send your message to us

Injection molding machine LOG-320S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords