injection molding machine LOG-250S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG

Model Number: LOG 250S8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 625

Clamping Force: 2500kn

Opening Stroke: 520mm

Power(W): 29kw

Certification: CE

After-sales Service Provided: Engineers available to service machinery overseas

Packaging & Delivery

| Packaging Details: | 20GP,40GP,40HQ |

|---|---|

| Delivery Detail: | 30 Days |

Product performance and advantages:

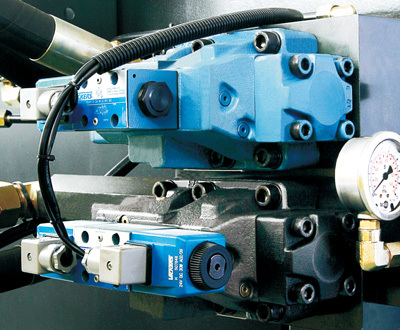

1. Servo energy-saving system

Using the servo motor oil electricity composite structure

2. Servo motor high response feature

It costs only 0.05s for servo energy saving injection molding machines to achieve the maximum output, in comparison with conventional hydraulic injection molding machines. The response speed has been obviously increased, improving the production efficiency.

3. Unique function

Large colored screen with TFT interface

Full automatic close-loop control

Module design of hardware

Auto-tune PID temperature control

Pc interface USB, PIC, and FLASH…

Curve monitoring and analysis function

K-can data transmission (500Kbit/s)

On-line central monitoring function

LOG-250S8 Technical parameters

Description | Unit | LOG-250S8 | ||

international recognized models | 1140/250 | |||

injection | A | B | C | |

Tjeoretical injection volume | cm³ | 510 | 687 | 863 |

Shot volume | g | 464 | 625 | 785 |

Oz | 16.2 | 21.8 | 27.4 | |

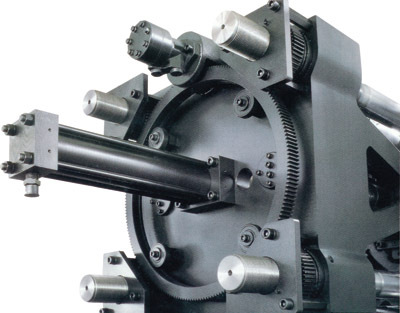

Screw diameter | mm | 50 | 58 | 65 |

Injection diameter | mpa | 224 | 166 | 132 |

Screw L:D ratio | 24:1 | 21:1 | 18.7:1 | |

Scerw steoke | mm | 260 | ||

Screw rotate speed | r/min | 0-180 | ||

CLAMPING UNIT | ||||

Clamping force | kN | 2500 | ||

Opening stroke | mm | 520 | ||

Platen size | mm*mm | 820*790 | ||

Space between tie bars | mm*mm | 560*530 | ||

Maldthickness | mm | 200-580 | ||

Platen Mix stroke | mm | 1100 | ||

Ejection stroke | mm | 150 | ||

Ejcetion force | kN | 67 | ||

Power/Elcetric Heating | ||||

Hydralic system pressure | Mpa | 17.5 | ||

Pump motor | kw | 29 | ||

Heating power | kw | 16 | ||

Number of temp.conteol | 4+nozzle | |||

Other | ||||

Cycle time | sec | 4.8 | ||

Tank volume | L | 380 | ||

Machine dimesions | m*m*m | 6.2*1.46*2.15 | ||

Weight of machine | kg | 8000 | ||

- Q: The proportion of each kind of introduction? Molding shrinkage? Molding temperature? Drying conditions? Overall performance? Mainly for use. I sell plastic parts and I want to make a wall calendar.

- PMMA poly methyl methacrylate (PMMA)PC polycarbonatePOM POMTeflon, PFA PTFE (Te Fulong)CN cellulose nitrate (Sai Lulu)Specific technical parameters,

- Q: Injection molding machine, blister machine, blow molding machine, what is the fundamental difference?

- Such as: casing, orange, pen, barrel, tube and so on.Plastic suction machine - plastic sheet (film) heating, according to the shape of the mold molding method of producing all kinds of plastic products machinery.

- Q: What is the percentage of nozzles in injection molding machines?

- According to the 100 degree metaphor, the setting 50% is 50 degrees

- Q: How many tons is the injection machine of 4 Ann?

- Ann is the name of Hongkong in the last century. Ann means the amount of injection, and tons, that is, clamping force. generally speaking3 Ann -----60T4 Ann -----90T7 Ann -----120T10 Ann -----160T14 Ann -----210T17 Ann -----250T

- Q: How is the screw speed of injection molding machine adjusted? Who knows very well?.

- Injection molding machine screw speed, first, adjust the injection molding machine pre molding pressure and flow, and then adjust the back pressure

- Q: The outer ring of the injection machine is against the ring. Do you blame the anti ring?It was normal to play PBT before. Now the storage stroke is 10 centimeters long or unstable

- If you have any questions, or do you know?. My tip: if the screw turns during the injection, it means that the check ring is damaged or the component of the reverse ring is leaking. This is what I did for many years before I mastered it. Wish you success in your work!

- Q: What exactly does the KO hole in the injection mold mean? Where is the general position?

- The KO hole, also called the top roller hole, is made on the rear die panel of the mould. The top rod can be directly pushed to the thimble plate when the injection top is out, and the hole dug on the panel is used for avoiding the empty. KO with the sprue hole position is on the same axis.

- Q: For example, according to the shape, the injection quantity, clamping force, and electric, all electric ^^^ hope to get a more comprehensive answer Thank you!!!

- Shape can be divided into: horizontal, verticalInjection molding, then small to the product weight, 1G large to a few kilograms have, quite a lot.Because now the injection molding machine manufacturers are based on customer demand to do injection molding machine configuration, such as the general 180T clamping force of the frame, with 36-38mm screw, now the same rack can be the smallest 20mm screw. Should say, as long as you ask what kind of can match what kind of, so that the injection molding, mold force is now not necessarily, according to your product requirements to configure!

- Q: How does the injection machine set up the die segments and the pressure and speed of each segment? Seek advice.

- Then enter the low voltage protection process.Low pressure process with 0 speed, 0 pressure for the best, special circumstances increased to less than 20%20bar. The distance is at the end of the starting point of the high voltage die.High voltage medium and low speed 40-60%, medium high voltage 60-100bar is appropriate. The starting position is the termination position of the die closing +3-5mm.Among them, the determination of the fast termination position and the low voltage termination position is particularly important.Speed and pressure focus on the smooth movement of the die without vibration. Special attention is paid to the setting method of low voltage protection.The above is personal experience, and I hope to help you.

Send your message to us

injection molding machine LOG-250S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords