Injection Molding Machine LOG-160A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A8 CONFIGURATIONS

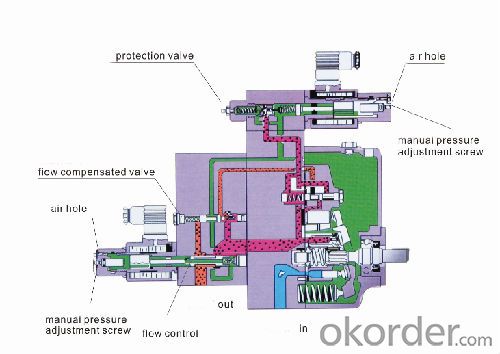

PROPORTIONAL VARIABLE PUMP YUKEN

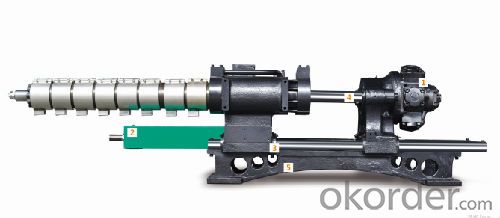

OIL MOTOR INTERMOT

DIRECTION VALVE VICKERS

COMPUTER MIRLE 9118

AC CONTACTOR SCHNEIDER

ELECTRONIC RULER NOVO

LUBICATION PUMP HERG

Quick Details

Condition: New

Type: Other

Style: Horizontal

Brand Name: LOG

Model Number: LOG-160A8

Place of Origin: China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 260---368G

Clamping Force: 1600KN

Opening Stroke: 430MM

Power(W): 15kw

Certification: CE

After-sales Service Provided: Engineers available to service machinery overseas

LOG160-A8 energy-saving plastic injection moulding machine

| Description | Unit | LOG-160A8 | ||

| international recognized models | 525/160 | |||

| injection | A | B | C | |

| Tjeoretical injection volume | cm³ | 277 | 318 | 392 |

| Shot volume | g | 260 | 298 | 368 |

| Oz | 9.1 | 10.5 | 12.9 | |

| Screw diameter | mm | 42 | 45 | 50 |

| Injection diameter | mpa | 190 | 166 | 135 |

| Screw L:D ratio | 21.4:1 | 20:01 | 18:01 | |

| Scerw steoke | mm | 200 | ||

| Screw rotate speed | r/min | 0-200 | ||

| CLAMPING UNIT | ||||

| Clamping force | kN | 1600 | ||

| Opening stroke | mm | 430 | ||

| Platen size | mm*mm | 680*680 | ||

| Space between tie bars | mm*mm | 460*460 | ||

| Maldthickness | mm | 180-500 | ||

| Platen Mix stroke | mm | 930 | ||

| Ejection stroke | mm | 140 | ||

| Ejcetion force | kN | 50 | ||

| Power/Elcetric Heating | ||||

| Hydralic system pressure | Mpa | 17.5 | ||

| Pump motor | kw | 18.7 | ||

| Heating power | kw | 12.6 | ||

| Number of temp.conteol | 4+nozzle | |||

| Other | ||||

| Cycle time | sec | 2 | ||

| Tank volume | L | 210 | ||

| Machine dimesions | m*m*m | 4.95*1.25*2.0 | ||

| Weight of machine | kg | 5100 | ||

- Q: 110 tons injection molding machine injection quantity is how many grams?

- The amount of injection is not only related to the size of the tonnage, but also related to the diameter of the screw. Each brand of injection molding machine is not necessarily the same.The screw diameter 45mm is probably around 215g, and the 38mm is around 200g.This data is not certain, still depends on the specific brand and screw size, to accurate value, only manufacturers can tell you.

- Q: Every time the adhesive is stable, the glue is basically stable, but about 100 of the 2-3 die will not be in place, for example, the 50MM will stop

- The injection time is not enough, the pressure of 50mm injection is not enough

- Q: How to repair the injection machine?

- Common faults in the use of injection molding machines and solutions are as follows:Part 1: Problems and treatment methods of mould locking parts:(1) not locking dies:Handling method: 1) check the front travel switch of safety door and repair it.2) check the 24V5A power in the electric box, replace the insurance and the power box.3): check whether the spool is stuck, cleaning the spool.4): check whether the output of the I/O board, the solenoid valve is charged.5): check whether the hydraulic safety switch is closed, whether the mechanical lock rod is opened or not.(two) the opening and closing of the die machine:Handling method: 1) check whether the lubricating oil pipe is broken or, if so, reconnect the tubing.2): small amount of lubricating oil, lubricating oil amount increase, 50 die once or manually add oil and lubricating oil.3): clamping force, check whether the mold needs large clamping force, lower the clamping force.4): the current fluctuation of the amplifier board, check whether the current parameters meet the acceptance criteria, re adjust the current value.5): parallelism error indicator check head board parallelism is greater than the acceptance criteria; adjust the parallelism.

- Q: The outer ring of the injection machine is against the ring. Do you blame the anti ring?It was normal to play PBT before. Now the storage stroke is 10 centimeters long or unstable

- If you have any questions, or do you know?. My tip: if the screw turns during the injection, it means that the check ring is damaged or the component of the reverse ring is leaking. This is what I did for many years before I mastered it. Wish you success in your work!

- Q: What is the injection molding machine back pressure, back pressure role is what?

- Adjustment of back pressureThe adjustment of the injection back pressure shall be determined according to the raw material performance, drying conditions, product structure and quality, and the back pressure should be adjusted at 3-15kg/cm 3. When the surface of the product has little Qihua, mixed color, shrink and product size and weight changes, may be appropriate to increase the back pressure. When the nozzle leakage glue, salivation, Melt Overheating product decomposition, discoloration and feeding back too slow may be considered appropriate to reduce the back pressure.Back pressure is one of the important parameters to control melt quality and product quality in injection molding process. Proper back pressure plays an important role in improving product quality, and can not be ignored!

- Q: What does "120T 140T" mean in an injection machine?

- For example, the production of PVC, will be shallow groove.Ann and T conversion is quite troublesome, here only give some common types of control: injection molding machine 4 (50T) 8 sets of injection molding machine 6 (120T) 8 sets of injection molding machine 8 (140T) 5 sets of injection molding machine 12 (160T) 5 sets of injection molding machine 16 (180T) 3 sets of injection molding machine 18 (200T) 4 sets of injection molding machine 24 (250T). Injection molding machine: injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity. According to the arrangement of injection device and mould locking device, they can be divided into vertical type, horizontal type and vertical horizontal compound type.

- Q: Does the wear of the reverse ring of the injection machine cause yellow lines and spots?

- Screw, cylinder, nozzle has research injury or spot, will cause hanging material, easy to cause material change color. Check ring wear, try to use the following method, the spray nozzle can be not heated, and then use a low injection pressure discharge (slowly increase the injection pressure), nozzle material but not shoot; injection stop after level changes; repeat. If the material level is less and less, until zero. The back ring is worn out, and the wear degree of the backstop ring can be judged according to the speed of the material turnover.

- Q: How does the injection machine prevent the product from sputtering to the machine? As for the question, how can I solve it perfectly?

- It's time to slow down. Is it a launch rocket? It's too vigorous. Not really. Just use a cardboard file

- Q: How big is the minimum injection molding machine?

- Horizontal injection molding machine is generally the smallest in 40T, vertical minimum is 3T, the amount of injection is 15g, the working voltage is 220V, the power consumption is 0.8kw/h.Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. It is divided into vertical, horizontal and all electric type. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.

- Q: What are the injection molding machine brands in China?

- Factors affecting user purchasesIndustry trends in the purchase of injection molding machines by users5, the survey of purchasing plan shows that 51% of users have purchasing plan. Among them, foreign-funded enterprises accounted for 40%, private enterprises accounted for 30%, joint-stock enterprises more than 20%, while state-owned enterprises less than 10%. Most of these users of the purchase plan belong to the automotive industry, followed by the packaging and electronic communications equipment industry.6, when asked whether the user will buy again in the use of brand, 36% of users are positive, 14% of users clearly will not, 50% of users expressed uncertainty.That is, the number of respondents surveyed and many factors such as uneven distribution of trade restrictions, although the investigation has a certain objectivity, but can not fully reflect the real situation of the market, only for your reference.

Send your message to us

Injection Molding Machine LOG-160A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 720 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords