Black Drop Golden Suspension Ceiling Grid - Hot Sales

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Flat Suspension Grids) Description

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

2,Main Features of the (Flat Suspension Grids)

Shape:Plane,groove

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized steel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic cold roll forming and punching machineries guarantee the high precision.

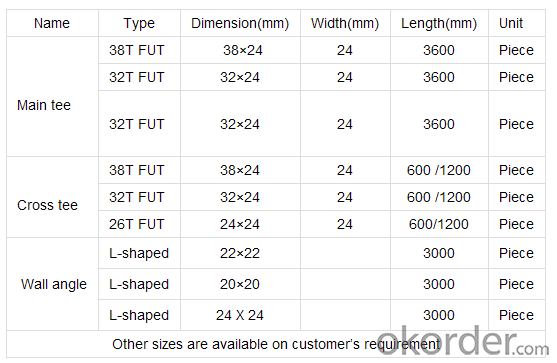

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

3,(Flat Suspension Grids) Images

4,(Flat Suspension Grids) Specification

5,FAQ of (Flat Suspension Grids)

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Using fire proof material to assure living safety.

4. Can be installed according to practical demands.

5. The physical coefficient of all kinds Suspension

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

- Q: what should I charge to install 1500 sq feet of drop ceiling

- Drop Ceiling Installation Cost

- Q: Light steel keel gypsum board ceiling, hanging bar, the main keel, sub keel, cross-keel spacing is how much

- The distance between the main keel is generally between 80 and 120 cm, depending on the use of thick gypsum board, if the gypsum board thick, or double gypsum board, the main keel spacing is small, and vice versa can be appropriate Enlarge the number, but not more than 1.2 meters; hanging bar spacing, is the same, according to the size of the main keel to determine the distance between hanging bars and hanging bars, but the same can not exceed 1.2 meters; sub keel (50 keel ) Spacing, the general use of 9.5mm gypsum board when it is 30 cm, if the thickness of the gypsum board is 12mm, the distance between the vice keel can be enlarged to 40 cm. But here we are basically using 30 cm spacing of.

- Q: does anyone know where I can find clips to hang things from acoustic ceiling grids?

- use bent out paper clips...

- Q: Pure light steel keel ceiling how much money a square, Bao Gong Bao material

- Give it to the 2B of the 2B! This price is very 2B ah

- Q: Gypsum board light steel keel cut off how much money 1 square

- Light steel keel skeleton 20 yuan per square meter, gypsum board double-sided 1.2cm thick plus 18 yuan / square, labor costs in about 20 yuan / square, if placed on the noise cotton to add 3, plus loss, other dressings generally About 65 yuan (without paint)

- Q: Decorative lights open to the light steel keel how to do

- Can be displaced, in the case of non-shift, saw off the vice keel, and then in the side to add a vice keel or wooden side. If it is only a downlight cut off a deputy dragon, you can not add. The main keel saw to add the boom.

- Q: How to distinguish the quality of light steel keel

- In fact, distinguish the quality of the keel is very simple: First, weigh the weight of the keel Second, look at the surface of the keel rust treatment : The current point is a little better hot-dip anti-rust treatment, I personally think that the keel surface treatment is not very important, even light steel keel even rust or years or 10 years to put the keel rust off. So the owners do not have to worry when buying.

- Q: They're usually square-shaped with grid wire.They usually have lights behind them. I'm looking for only one. Any ideas where I could get one?

- All your big box stores such as Home depot or Lowes will carry them. Any electrical supply house will also carry them. They are most of the time a white or clear plastic. Any questions you can e mail me through my avatar. GL

- Q: My family bathroom and living room between the non-load-bearing walls, do not want to tear down all, just want to bathroom door from the left side of the wall to the right. Decoration said, do light steel keel wall to the left side of the door plug. So there will be no problems with the toilet tiles ah?

- Decoration said that stand up is not strong, than the original wall and thin two or three centimeters

- Q: I am putting in an electrical outlet behind a wall and I am looking above the wall by moving a ceiling tile. After moving a ceiling tile, I found that there is a light wired behind the ceiling tiles, a place nobody would be able to see it. I can't see where to turn this on, and it is not a problem, it has just made me curious. I live in a 95+ person fraternity house if that makes any difference.

- The light used to be on the finished ceiling when the structure was first built. Later a drop ceiling was added and they just left the old lights up there. They were probably controlled by the switch that you currently use to turn the troffer lights on that are mounted in the ceiling grids.

Send your message to us

Black Drop Golden Suspension Ceiling Grid - Hot Sales

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords