Drop Ceiling Grid Covers - Suspension Ceiling Grid System 3660mm Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 150000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Flat Suspension Grids) Description

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

2,Main Features of the (Flat Suspension Grids)

Shape:Plane,groove

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized steel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic cold roll forming and punching machineries guarantee the high precision.

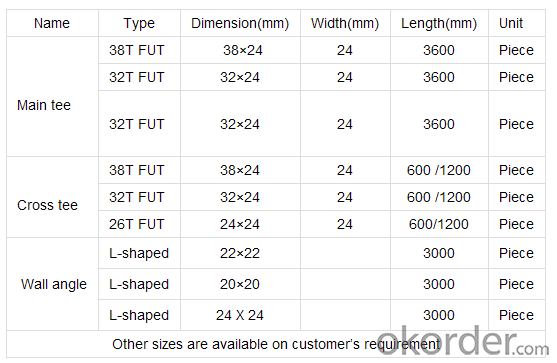

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

3,(Flat Suspension Grids) Images

4,(Flat Suspension Grids) Specification

5,FAQ of (Flat Suspension Grids)

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Using fire proof material to assure living safety.

4. Can be installed according to practical demands.

5. The physical coefficient of all kinds Suspension

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

- Q: Light steel keel hanging shed, a day of work can work out how much work?

- Different construction requirements, construction conditions, the skilled proficiency of workers and other factors, will affect the construction of the workload of the number. In addition, the shape of the ceiling, the amount of live will be subject to constraints

- Q: Specification for lightweight steel keel and gypsum board

- Its length is generally 3m, 4m. Gypsum board specifications, the thickness of 9.5mm, 12mm, 15mm, there are some thickness below 9.5mm, but generally belong to non-standard; length of 2400mm, 3000mm, width of 1200mm The

- Q: Do you need a light steel keel or a wooden keel base? If there is, usually light steel keel or wood keel, if it is wood keel, need to brush what paint, fire paint to brush it?

- Not required. The process standard for industrial and civil construction works, the exterior panel dry hanging process. The process is the use of corrosion-resistant bolts and corrosion-resistant flexible connectors, marble, granite and other decorative stone dry hanging on the outer surface of the building structure, stone and structure between the left 40 ~ 50mm cavity. The finishes made with this process allow an appropriate amount of displacement to be absorbed by wind and seismic forces to absorb part of the wind and earthquakes without cracking and shedding. When the wind and the earthquake force disappears, the stone is also reset with the structure. Compared with the traditional wet operation process, the process can eliminate the grouting process, can shorten the construction period, reduce the building weight, improve the seismic performance, more importantly, effectively prevent the grouting in the salt and other pigment penetration of stone pollution, Its decorative quality and perception effect. In addition, due to seasonal changes in outdoor temperature caused by changes in the outer surface expansion and contraction, so that the decorative panels may fall off, this process can effectively prevent the occurrence of worn off the board accident. This dry pendant panel installation process can also be used with glass curtain wall or large windows, metal trim panel installation process and other supporting applications. Now many large domestic public building stone interior and exterior trim panel installation works to dry hanging process is becoming increasingly common.

- Q: What kind of work is the steel keel wall?

- Is a carpenter. I was doing light steel keel Oh

- Q: U-type and C-type light steel keel purposes

- C-type keel is a vice keel (curved keel) fixed on the main keel.

- Q: Light steel keel or paint keel good kitchen ceiling, light steel keel and paint keel, I do not know which is good?

- Surely it is paint keel

- Q: how do you level ceiling grid for acoustic ceilings?

- The cheapest way is a tube level. Fill a long clear plastic tube with water. (Long enough to reach all around the room.). The level in both ends will be the same. If you fix one end at your reference point you can move the other end anywhereon the grid, and the water level will be the same as the reference point.

- Q: Material u-type 50 series light steel keel in the main keel specifications is how much

- Simply talk to you about the connection between the keels: the boom with a bolt bolts fixed on the floor, with T-type keel hanging pieces connected T-shaped main keel, T-keel for long, in its interface with T-keel connections fixed, between the keel and the main keel is connected between the plug, you can not accessories. If the ceiling has an additional load or a large area of the ceiling, you need U-bearing keel, that is, after the installation of the boom, first with U-shaped keel (main keel) hanging pieces will U-shaped main keel and boom connection, T-type keel pendant connects the T-shaped longitudinal keel with the U-shaped main keel ... 1, T-type keel hanging pieces: for the T-type main keel and boom connection. Applicable only to non-loaded keel without additional load of the ceiling. 2, T-type keel connection: for the vertical T-keel that is the main keel connection. 3, U-type keel hanging pieces: for connecting the carrying keel (main keel) and boom. 4, T-type keel pendant: for U-type light steel keel and T-type longitudinal keel connection. 5, U-shaped main keel connection: for the U-type carrying keel of the long.

- Q: What is the distance between the main keel? How much is the distance between the keel? What is the spacing of the hanging bars?

- The main dragon spacing is 1 meter, vice-long distance is 30CM, hanging spacing is 1-1.2 meters

- Q: The existing light steel keel partition wall of the location is not good, would like to change another position, is to block the original door, and then open a door in the original door door, experts told me how to construction?

- Plug the door with light steel keel or wood keel seal gypsum board can be, gypsum board interface with a bandage and then paint; light steel keel is easy to cut, open the door is not a problem, load-bearing door frame can be made with steel skeleton, The steel frame and the ground can be welded with angle steel, the angle of the corner with the expansion bolts fixed, steel, in particular, the steel frame and the light steel keel main dragon with wire connection fixed to increase the load-bearing capacity and integrity, Welded attention to rust, and then sealed plate cover, do the door can be trim.

Send your message to us

Drop Ceiling Grid Covers - Suspension Ceiling Grid System 3660mm Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 150000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords