High Quality Hot Rolled Thick Aluminum Roofing Sheets for Canada

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Hot Rolling Thick Aluminum Sheet Description:

Hot Rolling Thick Aluminum Sheets are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Hot Rolling Thick Aluminum Sheet:

Good mechanical properties.

Easy processing, wearability.

Corrosion resistance

Resistance to oxidation.

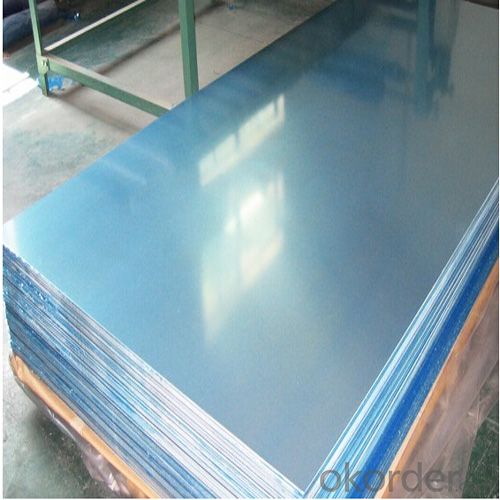

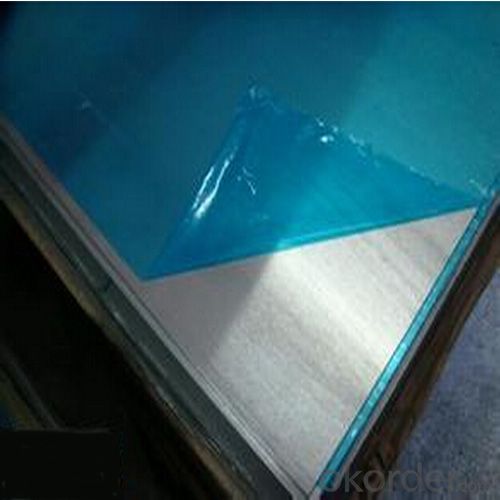

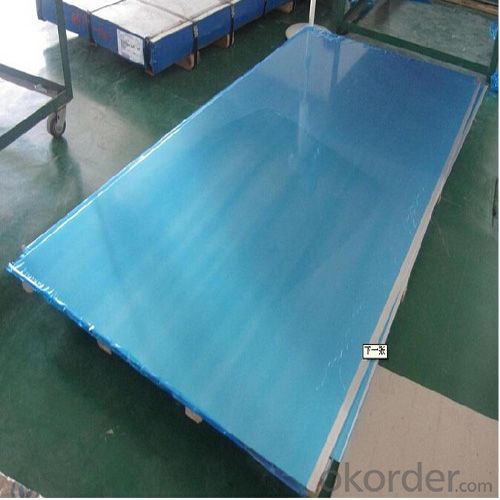

3. Hot Rolling Thick Aluminum Sheet Images:

4. Hot Rolling Thick Aluminum Sheet Specification:

| Aluminium sheet | |||||

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Consider an aluminum wire of diameter 0.580 mm and length 28.0 m. The resistivity of aluminum at 20.0°C is 2.82 10-8 Ω · m.(a) Find the resistance of this wire at 20.0°C. ___________Ω(b) If a 9.00-V battery is connected across the ends of the wire, find the current in the wire. __________A

- Resistivity Of Aluminum Wire

- Q: Why must the aluminum oxide be electrolyzed in a molten cryolite solution?

- To electrolyse aluminium oxide, it has to be molten. However, the melting point of Al2O3 is extremely high ( 1000°C), and that would make the electrolysis very inefficient. However, Al2O3 dissolves in cryolite at much lower temperatures (lower than 900°C), which makes it a much more viable process.

- Q: How are aluminum sheets different from aluminum plate?

- Aluminum sheets and aluminum plates are two forms of aluminum metal that differ primarily in terms of thickness. Aluminum sheets are typically thin, flat pieces of aluminum that are less than 6mm thick. They are commonly used in applications where lightweight and flexibility are important, such as in the construction of aircrafts, automobiles, and electronic devices. On the other hand, aluminum plates are thicker and heavier than sheets, typically measuring 6mm or more in thickness. Plates are often used in applications that require strength and durability, such as in the construction of heavy machinery, structural supports, and marine equipment. While both sheets and plates are made from aluminum, their distinct thicknesses make them suitable for different purposes.

- Q: What is the typical cost-effectiveness of aluminum sheets compared to other materials?

- The cost-effectiveness of aluminum sheets compared to other materials can vary depending on various factors such as the specific application, size, thickness, and market conditions. However, in general, aluminum sheets are often considered to be cost-effective due to their unique properties and versatility. Aluminum is a lightweight material, which means less material is needed to achieve the same strength as heavier alternatives. This can result in cost savings in terms of transportation, installation, and overall project expenses. Additionally, aluminum sheets offer excellent corrosion resistance, durability, and a long lifespan, which can further contribute to their cost-effectiveness over time. Furthermore, aluminum is highly recyclable, allowing for significant savings in terms of energy and resources during the recycling process. This recyclability also adds to the overall cost-effectiveness of aluminum sheets, as they can be reused or repurposed rather than disposed of as waste. While the initial cost of aluminum sheets may be higher compared to some other materials, the long-term benefits and savings they offer often outweigh the initial investment. It is important to consider factors such as durability, maintenance costs, energy efficiency, and environmental impact when evaluating the cost-effectiveness of aluminum sheets compared to other materials. Ultimately, the typical cost-effectiveness of aluminum sheets compared to other materials will depend on the specific requirements and circumstances of each project. It is advisable to consult with industry experts or suppliers to evaluate the cost-effectiveness of aluminum sheets in relation to other materials for a particular application.

- Q: Hey.How come iron rust and aluminium does not?DETAILED ANSWER PLEASE.I want to understand this...THANKS.

- Iron is the only metal that rusts (apart from steel which is made from iron), aluminum just like titanium forms an oxide of 3 or 4 atoms on the surface, while rust is the oxide of iron ) rusting is an example of corrosion -- an electrochemical process involving an anode (a piece of metal that readily gives up electrons), an electrolyte (a liquid that helps electrons move) and a cathode (a piece of metal that readily accepts electrons). When a piece of metal corrodes, the electrolyte helps provide oxygen to the anode. As oxygen combines with the metal, electrons are liberated. When they flow through the electrolyte to the cathode, the metal of the anode disappears, swept away by the electrical flow or converted into metal cations in a form such as rust. For iron to become iron oxide, three things are required: iron, water and oxygen.

- Q: Can aluminum sheets be anodized in different finishes?

- Yes, aluminum sheets can be anodized in different finishes. Anodizing is an electrochemical process that enhances the natural oxide layer on aluminum, making it thicker and more durable. This process can be customized to achieve various finishes such as clear, colored, or even textured surfaces. The type of finish depends on factors like the alloy composition, anodizing method, and the desired appearance. Anodized aluminum sheets are widely used in various industries including architecture, automotive, and electronics due to their corrosion resistance, aesthetic appeal, and ability to retain color over time.

- Q: Can aluminum sheets be used for cryogenic applications?

- Yes, aluminum sheets can be used for cryogenic applications. Aluminum has good thermal conductivity and low density, which makes it suitable for cryogenic environments. It can withstand extremely low temperatures without becoming brittle or losing its mechanical properties. Additionally, aluminum is non-magnetic and has excellent resistance to corrosion, which is important in cryogenic applications. However, it is worth noting that the specific alloy and thickness of the aluminum sheet should be carefully selected based on the specific cryogenic temperature and application to ensure optimal performance.

- Q: This question asks for a comparison between the benefits and drawbacks of utilizing products made from recycled aluminum.

- <p>Advantages of using recycled aluminum products include reduced energy consumption, lower greenhouse gas emissions, and a decrease in the need for raw material extraction. It also promotes waste reduction and supports a circular economy. Disadvantages might include potential quality concerns, as recycled aluminum might not always meet the same strength and durability standards as new aluminum. Additionally, there can be higher initial costs associated with recycling processes and the need for advanced sorting and processing technologies.</p>

- Q: What does 3003-O aluminum mean?

- H-- strain hardening statusO-- annealed state (the softest of all States)T-- heat treatment status

- Q: What does aluminum plate "1060-H24" mean?

- Each digit in the 1060-H24 stands for the following meanings:First, a number of Arabia 1 is representative of pure aluminum (aluminum is aluminum content above 99% aluminum, in addition to the beginning and start with 2-8 are 2### for copper and aluminum magnesium alloy, 3### aluminum manganese alloy, 4### alloy, 5### alloy and so on)

Send your message to us

High Quality Hot Rolled Thick Aluminum Roofing Sheets for Canada

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords