Hot Rolled unequal Angle Steel for Bridge Girder Framework

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

Specifications of Hot Rolled unequal Angle Steel for Bridge Girder Framework

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2. Invoicing on theoretical weight or actual weight as customer request3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR.

4. Payment terms:

1).100% irrevocable L/C at sight.

2).20% T/T prepaid and the balance against the copy of B/L.

3).20% T/T prepaid and the balance against L/C

5.Sizes:

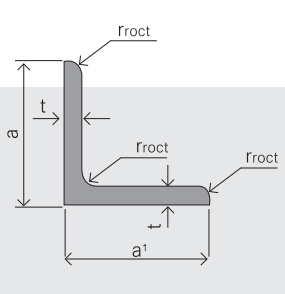

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

Usage & Applications Hot Rolled Angle Steel

According to the needs of different structures, Angle can compose to different force support component. It is widely used in various building structures and engineering structures such as roof beams, hoisting machinery and transport machinery, ships, container frame and warehouse etc.

Packaging & Delivery of Hot Rolled unequal Angle Steel for Bridge Girder Framework

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 35MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in container, or by bulk cargo, also we could do as customer's request.

- Q: How do steel angles perform under dynamic loads?

- Steel angles generally perform well under dynamic loads due to their inherent strength and durability. The structural shape of steel angles, characterized by their L-shaped cross-section, provides excellent resistance to bending and torsional forces. This design allows them to efficiently distribute dynamic loads and resist deformation, making them suitable for various applications in construction, engineering, and manufacturing industries. However, the specific performance of steel angles under dynamic loads can vary depending on factors such as the grade and quality of the steel, the magnitude and frequency of the dynamic load, and the overall design and reinforcement of the structure.

- Q: Can steel angles be used in seismic or earthquake-resistant construction?

- Yes, steel angles can be used in seismic or earthquake-resistant construction. Steel angles are commonly used in structural applications as they provide strength and stability to a structure. In seismic or earthquake-resistant construction, the primary goal is to design and construct buildings that can withstand the forces generated by an earthquake. Steel angles can be utilized in various ways to enhance the seismic resistance of a structure. One common application is to use steel angles as bracing elements. Bracing systems are employed to help distribute the seismic forces throughout the structure, reducing the possibility of collapse. Steel angles can be used as diagonal bracing members, providing additional strength and stiffness to the building. Additionally, steel angles can be used as moment-resisting frames in seismic design. Moment-resisting frames are designed to dissipate and absorb the energy generated during an earthquake. By incorporating steel angles into the frame, the structure can effectively resist the lateral forces and remain stable during seismic events. Moreover, steel angles can be employed in the construction of steel moment frames, which are widely used in seismic design. These frames consist of steel columns and beams connected by steel angles or other connections capable of resisting the forces induced by an earthquake. Steel angles play a crucial role in transferring forces between the different members of the frame, ensuring the overall stability and integrity of the structure. In conclusion, steel angles can be effectively utilized in seismic or earthquake-resistant construction. Their strong and versatile nature makes them suitable for bracing systems, moment-resisting frames, and steel moment frames, all of which contribute to enhancing the seismic resistance of a structure. However, it is crucial to ensure that the design and installation of steel angles comply with the relevant building codes and regulations to guarantee the safety and durability of the construction.

- Q: How are steel angles tested for quality and strength?

- Steel angles are tested for quality and strength through various methods to ensure they meet the required standards and specifications. One of the primary tests conducted on steel angles is the tensile test, which measures the material's resistance to breaking under tension. This test involves applying a gradually increasing load to a sample of the steel angle until it reaches its breaking point. The maximum load the angle can withstand is measured, and this provides critical information about its tensile strength. Another important test is the hardness test, which determines the steel angle's resistance to indentation. This test helps to assess the material's ability to withstand wear and tear, as well as its overall strength. Hardness is typically measured using the Rockwell or Brinell scales, where a harder material indicates higher strength. To ensure the steel angle's quality, it also undergoes visual inspections for any surface defects, such as cracks, uneven surfaces, or deformities. These inspections are conducted by trained professionals who carefully examine the angles for any imperfections that may compromise their structural integrity. In addition to these tests, steel angles may also undergo chemical composition analysis to verify that the material meets the required specifications. This analysis determines the percentage of various elements present in the steel, such as carbon, manganese, and sulfur, which directly impact the angle's strength and durability. Overall, steel angles are rigorously tested for quality and strength through a combination of physical, visual, and chemical tests. These tests ensure that the angles can withstand the intended loads and perform safely in various applications, providing confidence in their reliability and longevity.

- Q: Can steel angles be used for bracing?

- Yes, steel angles can be used for bracing. Steel angles are commonly used in construction and engineering projects to provide structural support and reinforcement. They are versatile and can be easily welded or bolted into place, making them suitable for various applications, including bracing. Steel angles are typically strong and rigid, which makes them effective in providing stability and resisting lateral forces. They are often used to brace columns, beams, and other structural elements, enhancing the overall strength and stability of the structure.

- Q: Can steel angles be used in the construction of transmission line towers?

- Yes, steel angles can be used in the construction of transmission line towers. Steel angles are commonly used in the construction industry for various applications, including the fabrication of transmission line towers. These towers are used to support overhead power lines and require strong and durable materials to withstand the weight and stresses imposed by the transmission lines. Steel angles are ideal for this purpose as they offer high strength and structural integrity. They can be easily fabricated into various shapes and sizes, making them suitable for the complex geometries and load requirements of transmission line towers. Additionally, steel angles are corrosion-resistant, which is crucial for structures exposed to outdoor elements, such as transmission line towers. Furthermore, steel angles provide cost-effective solutions for transmission line tower construction. They are readily available in the market and can be easily sourced and manufactured. Their versatility and durability make them a popular choice for engineers and designers involved in the construction of transmission line towers. In conclusion, steel angles are commonly used in the construction of transmission line towers due to their high strength, structural integrity, corrosion resistance, and cost-effectiveness.

- Q: What are the different surface finishes available for powder-coated steel angles?

- There are several different surface finishes available for powder-coated steel angles. These finishes are designed to provide varying levels of durability, aesthetics, and resistance to environmental factors. Some common surface finishes for powder-coated steel angles include: 1. Smooth or Glossy Finish: This is the most common surface finish for powder-coated steel angles. It provides a smooth and glossy appearance, giving the angles a sleek and attractive look. 2. Matte Finish: This surface finish has a low sheen or luster, providing a more subtle and understated appearance. Matte finishes are often chosen for their ability to hide fingerprints, scratches, and other imperfections. 3. Textured Finish: Textured finishes add a unique texture to the surface of the powder-coated steel angles. This can range from a lightly textured appearance to a heavily textured pattern, such as a hammered or pebble finish. Textured finishes not only enhance the aesthetics but also provide additional grip and resistance to slipping. 4. Metallic Finish: Metallic finishes simulate the look of metal, such as stainless steel or bronze, without the actual metal material. These finishes add a touch of elegance and sophistication to the powder-coated steel angles. 5. Wrinkle Finish: Wrinkle finishes create a textured, wrinkled appearance on the surface of the powder-coated steel angles. This finish is often used to hide imperfections in the metal and adds a unique visual appeal. 6. Antique Finish: Antique finishes are designed to give the powder-coated steel angles a weathered and aged appearance. This finish adds character and charm to the angles, making them suitable for vintage or rustic-themed applications. 7. Custom Finishes: In addition to these standard surface finishes, custom finishes can also be applied to powder-coated steel angles. This allows for greater creativity and flexibility in matching specific design requirements or achieving a desired aesthetic effect. It is important to consider the intended use, design preferences, and environmental conditions when selecting a surface finish for powder-coated steel angles. This will ensure that the finish chosen provides both the desired appearance and the necessary durability for the application.

- Q: Can steel angles be used for vehicle frames?

- Certainly, vehicle frames can make use of steel angles. In the construction sector, steel angles are frequently employed due to their structural robustness and adaptability. They possess a diverse array of uses, one of which is constructing vehicle frames. Steel angles offer exceptional support and stability, rendering them well-suited for bearing substantial loads and enduring the various strains and pressures encountered by a vehicle during operation. Furthermore, steel angles can be effortlessly welded or bolted together, allowing for flexibility in the design and construction of vehicle frames. Overall, steel angles present a dependable and long-lasting option for vehicle frames, guaranteeing the vehicle's structural integrity and safety.

- Q: Can steel angles be used as bracing elements in buildings?

- Yes, steel angles can be used as bracing elements in buildings. Steel angles are commonly used in construction for their strength and versatility. They are often used as structural components to provide lateral stability and support to buildings. Steel angles can be used as bracing elements to resist horizontal loads such as wind or seismic forces, helping to prevent excessive movement or deformation of the structure. They are typically installed at strategic locations, such as corners or intersections, and can be connected to other structural members using bolts or welds. Steel angles are preferred for bracing due to their high strength-to-weight ratio, durability, and ease of installation. Overall, steel angles are a reliable and commonly used solution for bracing elements in buildings.

- Q: Can steel angles be used for manufacturing ladders?

- Indeed, ladders can be manufactured using steel angles. The reason behind their frequent usage in ladder construction lies in their robustness and long-lasting nature. As they provide a solid framework and endure heavy burdens, they prove to be apt for ladder purposes. Moreover, steel angles exhibit resistance against bending and twisting, guaranteeing stability and security during ascent. Furthermore, they can be effortlessly joined together through welding or bolting to form the desired ladder structure. All in all, steel angles serve as a dependable option for ladder manufacturing.

- Q: Can steel angles be used for support frames in industrial machinery?

- Indeed, support frames in industrial machinery can make effective use of steel angles. Construction and fabrication often rely on steel angles for their remarkable traits of strength, durability, and versatility. These angles offer structural stability and support to a wide range of structures, including machinery frames. The availability of steel angles in multiple sizes and thicknesses allows for customization to meet precise load-bearing needs. Moreover, steel's inherent rigidity and exceptional tensile strength render it an optimal choice for supporting heavy machinery and equipment within industrial environments.

Send your message to us

Hot Rolled unequal Angle Steel for Bridge Girder Framework

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 120000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords