HIGH QUALITY GB STANDARD HOT ROLLED ANGLE BAR

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of Hot Rolled Steel Rebar:

The production process of Steel Rebar

1-Waling beam furnace 2-Roughing rolling group 3-Intermediate rolling train

4-Finishing rolling group 5-Water-cooling device 6-Walking beam cooler

7-Finishing equipment(including the cold scale shear,short feet collection system,

automatic counting device,bundling machine, collect bench)

Usage and Applications of Hot Rolled Steel Rebar:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

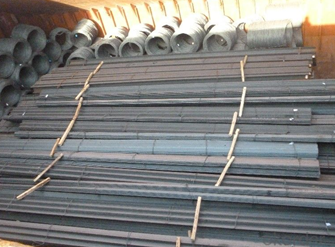

Packaging & Delivery of Hot Rolled Steel Rebar:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment terms: TT payment in advance or Irrevocable LC at sight.

Trade terms :FOB, CFR, CIF

Label:to be specified by customer, generally, each bundle has 1-2 labels

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Q235

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

- Q: What are the considerations for selecting the appropriate steel angle finish?

- When selecting the appropriate steel angle finish, there are several considerations to keep in mind. Firstly, the intended use and environment of the steel angle should be considered. If the angle will be exposed to harsh weather conditions or corrosive substances, a finish with high resistance to corrosion, such as galvanized or stainless steel, would be suitable. Additionally, the aesthetic requirements of the project should be taken into account. Different finishes, such as powder coating or painted finishes, can provide a range of colors and textures to enhance the appearance of the steel angle. Finally, the budget and cost-effectiveness of the finish should be considered, as some finishes may be more expensive than others. Overall, it is important to select a steel angle finish that meets both the functional and aesthetic requirements of the project while being compatible with the intended environment.

- Q: What are the different types of steel angles used in material handling systems?

- There are several types of steel angles commonly used in material handling systems, including equal angles, unequal angles, and l-shaped angles. These angles are used to provide structural support and stability to the system, allowing for the efficient movement and storage of materials.

- Q: Can steel angles be used for fencing or gating?

- Certainly, fencing or gating can indeed utilize steel angles. Steel angles are incredibly versatile and frequently employed in various construction endeavors, such as fencing and gating. They possess the essential attributes of strength, durability, and stability that are imperative for these particular applications. The assembly of a robust framework for fencing panels or gates can be effortlessly achieved by welding or bolting steel angles together. Moreover, these angles can be galvanized or coated to augment their resistance against corrosion, rendering them highly suitable for outdoor utilization. All in all, steel angles present a dependable and economically viable resolution for fencing and gating projects.

- Q: What are the advantages of using steel angles in manufacturing?

- There are several advantages of using steel angles in manufacturing. Firstly, steel angles are incredibly strong and durable, making them suitable for a wide range of applications. They can withstand heavy loads and provide structural stability, making them ideal for constructing buildings, bridges, and other infrastructure projects. Secondly, steel angles offer versatility in design. They can be easily customized and fabricated into various shapes and sizes, allowing manufacturers to create products that meet specific requirements. Whether it's a simple bracket or a complex framework, steel angles can be adapted to fit the desired design. Furthermore, steel angles have excellent corrosion resistance properties. They can withstand exposure to moisture, chemicals, and other environmental factors, which makes them suitable for outdoor applications and in industries where corrosion is a concern. Another advantage of using steel angles is their cost-effectiveness. Steel is a relatively inexpensive material compared to alternatives such as aluminum or stainless steel. Additionally, steel angles have a long lifespan, requiring minimal maintenance and replacement, which helps reduce overall costs in the long run. Lastly, steel angles are readily available in the market. They can be easily sourced from steel suppliers, making them accessible to manufacturers around the world. In conclusion, the advantages of using steel angles in manufacturing include their strength, versatility, corrosion resistance, cost-effectiveness, and availability. These factors make steel angles a preferred choice for various industries, enabling them to produce high-quality, durable, and cost-efficient products.

- Q: What are the different types of steel angles used in storage tank construction?

- Storage tank construction commonly utilizes several different types of steel angles, each serving a crucial role in providing structural support and stability. 1. L-angles, also referred to as unequal angles, find wide usage in storage tank construction. Comprising one longer and one shorter side, these angles form an L-shape. They are frequently employed as tank stiffeners, effectively preventing deformation and maintaining structural integrity. 2. T-angles, alternatively known as tee angles, represent another type of steel angle employed in storage tank construction. With a T-shape, one side is long while the other is shorter and perpendicular. T-angles often function as horizontal and vertical bracing members within tank structures, delivering added strength and stability. 3. Equal angles, also called right angles, consist of two equal sides forming a 90-degree angle. Tank construction commonly utilizes equal angles in various applications, such as providing support for tank roofs, reinforcing corners, or connecting tank components. 4. Bulb angles, or bulb flats, boast a unique shape featuring a flat surface and a bulbous section at one end. These angles are frequently employed in tank support structures, notably the tank bottom, to evenly distribute loads and minimize stress concentrations. 5. Rolled steel sections, such as I-beams, channels, and H-beams, are additionally utilized in storage tank construction alongside the aforementioned angle types. Rolled steel sections offer supplementary strength and support to tank structures, particularly in larger tanks or areas with high load requirements. In summary, the choice of steel angles in storage tank construction hinges upon specific design requirements, load considerations, and structural integrity needs. Selecting the appropriate type and size of angles is crucial to ensure tanks can withstand anticipated loads and environmental conditions.

- Q: What are the different welding methods used for steel angles?

- There are several different welding methods commonly used for steel angles, including Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), Flux-Cored Arc Welding (FCAW), and Gas Tungsten Arc Welding (GTAW). Each method has its own advantages and suitability for specific applications, but all are capable of effectively joining steel angles and providing strong, durable welds.

- Q: Can steel angles be used in the construction of oil refineries?

- Yes, steel angles can be used in the construction of oil refineries. Steel angles are commonly used in construction projects due to their high strength and durability. They provide structural support and are suitable for various applications, including the construction of oil refineries. The angles can be used to create frameworks, supports, and bracing for different components and equipment within the refinery. They offer stability and resistance to heavy loads and harsh environments, which is essential in the oil refining industry. Additionally, steel angles can be easily welded, bolted, or connected to other steel members, making them a versatile choice for refinery construction.

- Q: How do you store steel angles?

- Steel angles have various storage options depending on space availability and quantity. Here are a few commonly used techniques: 1. Vertical Storage: To store steel angles vertically, they can be leaned against a wall or placed on a storage rack. This method works well for smaller quantities, allowing easy access to each angle. It is crucial to ensure stability and secure positioning to prevent accidents. 2. Horizontal Storage: For larger quantities, steel angles can be stored horizontally. This can be achieved by stacking them on a pallet or using a compartmentalized storage rack. When stacking, it is important to evenly distribute the weight and use spacers between angles to prevent deformation. 3. Bundled Storage: When dealing with a large number of steel angles, bundling them together can be a convenient storage method. This involves tying the angles with steel strapping or using banding equipment. Bundling helps maintain organization and prevents shifting or falling during storage or transportation. Regardless of the chosen storage method, the following points should be considered: - Provide a clean and dry storage area to prevent rust or corrosion. - Ensure proper ventilation to avoid moisture buildup. - Keep angles away from direct sunlight and extreme temperature changes. - Regularly inspect for damage or corrosion. - Use appropriate lifting equipment and follow safety guidelines when moving or stacking steel angles.

- Q: Can steel angles be used in electrical or telecommunications applications?

- Yes, steel angles can be used in electrical or telecommunications applications. Steel angles are widely used in construction and engineering industries due to their strength and versatility. In electrical applications, steel angles can be used to mount electrical equipment, such as transformers or switchgear, to provide support and stability. They can also be used as structural components in electrical substations or power transmission towers. In telecommunications applications, steel angles can be used as mounting brackets for antennas or satellite dishes. They provide a sturdy and reliable support structure for these equipment, ensuring proper signal transmission. Additionally, steel angles can be used in cable management systems to organize and secure electrical or telecommunications cables. Overall, steel angles are a durable and cost-effective solution for various electrical and telecommunications applications.

- Q: Can steel angles be drilled or punched for fastening?

- Yes, steel angles can be drilled or punched for fastening.

Send your message to us

HIGH QUALITY GB STANDARD HOT ROLLED ANGLE BAR

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords