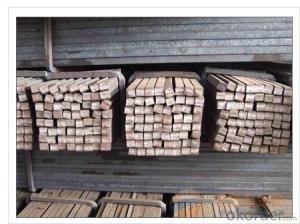

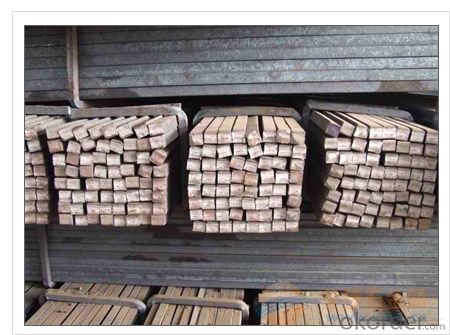

Hot rolled steel flat bar for construction made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot rolled steel flat bar for construction made in China at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot rolled steel flat bar for construction made in China are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot rolled steel flat bar for construction made in China are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

-Standard: GB,

-Grade: Q195 or equivalent.

-Chemical Composition:

Standard | Grade | Element (%) | ||||

GB | Q195 | C | Mn | S | P | Si |

0.06~0.12 | 0.25~0.50 | ≤0.050 | ≤0.045 | ≤0.30 | ||

Measures of HR Square Bar (small measures):

(Section of HR Square Bar)

-Length of a side and Theoretical weight of Square Bar.

Length of a side(mm) | Theoretical weight(kg/m) | Length of a side(mm) | Theoretical weight(kg/m) |

7 | 0.385 | 22 | 3.80 |

8 | 0.502 | 24 | 4.52 |

9 | 0.636 | 25 | 4.91 |

10 | 0.785 | 26 | 5.30 |

11 | 0.950 | 28 | 6.15 |

12 | 1.13 | 30 | 7.06 |

13 | 1.33 | 32 | 8.04 |

14 | 1.54 | 34 | 9.07 |

15 | 1.77 | 36 | 10.17 |

16 | 2.01 | 38 | 11.24 |

17 | 2.27 | 40 | 12.56 |

18 | 2.54 | 42 | 13.85 |

19 | 2.82 | 45 | 15.90 |

20 | 3.14 | 48 | 18.09 |

21 | 3.46 | 50 | 19.63 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, Formula for theoretical weight of Square bar: (length of a side)2 * 0.00785

3, The numbers with *mean that they are not regular or we don’t offer them.

-Regular length of Square Bar:

Steel | Length of a side (mm) | Length of steel (m) |

Normal steel | < 25 | 4~10 |

> 25 | 3~9 | |

Steel of high quality | All measure | 2~6 |

Tool steel >75 | 1~6 |

Usage/Applications of HR Square Bar:

-The Square Bar is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Packaging & Delivery of HR Square Bar:

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks: We make tag marks and color marks. The tag marks with white background and red company logo will be tied up to each bundle of the products. The information is usually including basic information of products and company and other information requested by customers. As for color marks, we will paint both ends of bundles to make sure that it will be more convenient for customers to distinguish them from other products.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation:

-The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products are usually transported to the nearest port from the production place.

FAQ:

Q1: How do we guarantee the quality of our products?

A1: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q2: Can stainless steel rust?

A2: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: Can a steel square be used for checking the accuracy of miter saw cuts?

- Yes, a steel square can be used for checking the accuracy of miter saw cuts. The straight edge of the steel square can be placed against the miter saw cut to ensure it is perfectly perpendicular or at the desired angle. This helps in achieving precise and accurate cuts.

- Q: Can a steel square be used for checking the squareness of a door frame opening?

- A door frame opening can be checked for squareness using a steel square. The steel square, also called a framing square or carpenter's square, is a versatile tool commonly used in carpentry and construction. It has a shape of a right angle, with one arm longer than the other, making it suitable for measuring angles and checking the squareness of objects. To check the squareness of a door frame opening, position the steel square against the inside corner of the frame. Ensure that the long arm aligns with one side of the frame, while the shorter arm aligns with the other side. If the frame is perfectly square, the edges of the square will fit perfectly against both sides of the frame. However, if the frame is not square, there will be a gap between the square and one or both sides of the frame, indicating the need for adjustments. Using a steel square is a reliable and precise way to check the squareness of a door frame opening. It enables the identification of any discrepancies and allows for necessary adjustments to be made, ensuring proper fit and functionality of the door.

- Q: How does a steel square assist in determining the correct angle for a sliding dovetail joint?

- A steel square assists in determining the correct angle for a sliding dovetail joint by providing a reliable and accurate measurement tool. A sliding dovetail joint requires precise angles to ensure a tight and secure fit between the two mating pieces. When using a steel square, it can be placed against the edge of the board or workpiece to establish a right angle or 90-degree angle. This is important as the sliding dovetail joint typically requires a 90-degree angle to create a strong and seamless joint. The steel square can be used to mark the layout lines on the workpiece by aligning it with the edge and drawing a line along the edge of the square. This helps to ensure that the angle is consistent and accurate throughout the joint. Additionally, the steel square can be used to check the angle of the dovetail joint during the cutting process. By placing the square against the joint, it can help verify that the angle is correct and that the cutting is being done accurately. Overall, a steel square serves as a valuable tool in determining the correct angle for a sliding dovetail joint, providing accuracy and precision throughout the joint-making process.

- Q: Can a steel square be used for siding installation?

- Yes, a steel square can be used for siding installation. A steel square, also known as a framing square or rafter square, is a versatile tool commonly used in carpentry and construction. While its primary purpose is for measuring and marking right angles, it can also be used as a guide for cutting and installing siding. When installing siding, a steel square can be used to ensure precise and accurate measurements for both horizontal and vertical cuts. It can be used to mark the angle and length of cuts on the siding material, allowing for a seamless fit and professional finish. Additionally, a steel square can be used to check the alignment and squareness of the siding during installation. This is important to ensure that the siding is level and straight, avoiding any potential issues or gaps in the finished result. Overall, a steel square is a valuable tool that can greatly assist in the siding installation process. Its ability to measure, mark, and guide ensures that the siding is installed correctly, resulting in a durable and visually appealing exterior for any building.

- Q: Can a steel square be used for checking the alignment of a jointer table?

- Yes, a steel square can be used for checking the alignment of a jointer table. A steel square is a versatile tool that can be used for various woodworking tasks, including checking the alignment of machinery. To check the alignment of a jointer table, you can place the steel square against the jointer's fence and table, ensuring that it is perfectly perpendicular. This will help you determine if the jointer table is properly aligned and if any adjustments need to be made. It is important to use a high-quality steel square that is accurate and reliable for accurate results.

- Q: How is a steel square different from a carpenter's square?

- A steel square and a carpenter's square are both measuring tools used in construction and woodworking, but they have some key differences. Firstly, the construction and material used in making these squares differ. A steel square is made entirely of steel, hence the name, and is generally heavier and more durable. On the other hand, a carpenter's square is typically made of wood with a metal edge or lip to ensure accuracy. In terms of design, a steel square has a longer body with a wider base and an L-shaped design with two arms that meet at a right angle. One arm is longer and serves as a measuring device, while the shorter arm is used as a guide for making precise cuts or angles. A carpenter's square, also known as a try square, has a shorter body with a right-angled shape, making it ideal for checking the accuracy of corners and marking 90-degree angles. Another difference lies in their functionality. A steel square is more versatile, as it can be used for measuring, marking angles, and laying out cut lines. It often includes additional features such as a level, protractor, and scribe, making it a comprehensive tool for various construction tasks. On the other hand, a carpenter's square is primarily used for checking right angles and ensuring squareness in woodworking projects. It is commonly used by carpenters and cabinetmakers for layout work, squaring up joinery, and verifying the accuracy of cuts and joints. In summary, while both steel squares and carpenter's squares serve similar purposes, their differences lie in their construction, design, and functionality. Steel squares are more durable and versatile, whereas carpenter's squares are simpler tools primarily used for checking right angles and ensuring accuracy in woodworking projects.

- Q: Can a steel square be used for checking the levelness of floors?

- The levelness of floors cannot be checked using a steel square. A steel square, also called a carpenter's square, is mainly utilized in woodworking to measure and mark right angles. It is not intended for accurately assessing surface levelness. To ensure the levelness of floors, it is recommended to employ a tool like a spirit level or laser level. These tools are specially designed for this task and offer precise measurements of horizontal or vertical levelness.

- Q: How do you use a steel square to find the center of an irregular shape?

- To find the center of an irregular shape using a steel square, follow these steps: 1. Ensure the steel square is properly aligned by placing it on a flat surface. 2. Position the irregular shape inside the square, ensuring it is fully contained and its edges are parallel to the square's sides. 3. Find the diagonal lines of the steel square by mentally connecting opposite corners. 4. Extend these diagonal lines beyond the square's edges. 5. Observe where the extended diagonal lines intersect the irregular shape. 6. Mark these points of intersection on the shape. 7. Connect the marked points with a straight line. 8. Repeat the process by rotating the steel square and aligning it with different edges of the shape. 9. The approximate center of the irregular shape is where the lines from multiple rotations intersect. It's important to keep in mind that using a steel square to find the center of an irregular shape provides an approximation, assuming the shape is symmetrical.

- Q: Can a steel square be used for shed layout and construction?

- Indeed, shed layout and construction can indeed make use of a steel square. Known by various names such as framing square or carpenter's square, this adaptable tool possesses the ability to measure and mark angles, ascertain squareness, and establish straight lines and right angles. Carpenters and builders commonly rely on this tool for diverse construction ventures, including the creation of sheds. Its steel composition ensures both accuracy and stability, rendering it a trustworthy companion in shed layout and construction. Be it the marking and cutting of lumber, the verification of squareness during assembly, or the guarantee of precise angles, a steel square proves to be an invaluable asset throughout the shed building process.

- Q: What are some common uses for a steel square in box making?

- Some common uses for a steel square in box making include measuring and marking right angles, checking for squareness and alignment of box corners, ensuring accurate and precise cuts, and verifying the straightness of box sides and edges.

Send your message to us

Hot rolled steel flat bar for construction made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords