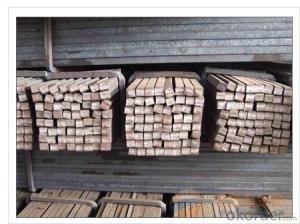

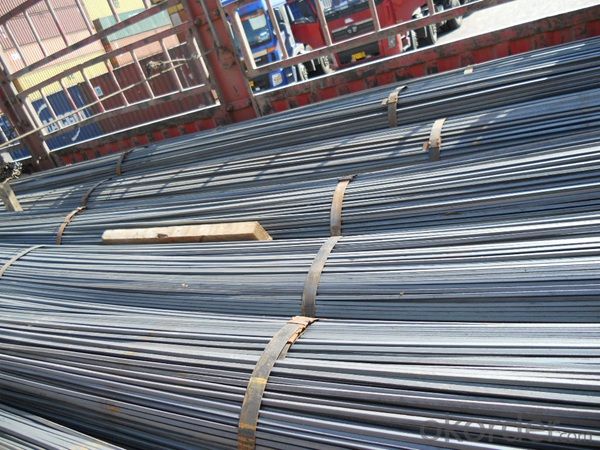

Hot Rolled MS Mild Square Steel Bars for Strcutures

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled MS Mild Square Steel Bars for Strcutures at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

-Row material for steel pipes.

Product Advantages:

Hot Rolled MS Mild JIS Steel U Channels for Strcutures are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

-Standard: GB,

-Grade: Q235 or equivalent.

Chemical Composition:

Standard | Grade | Element (%) | ||||

GB | Q235B | C | Mn | S | P | Si |

0.12~0.20 | 0.30~0.70 | ≤0.045 | ≤0.045 | ≤0.30 | ||

Measures of Hot Rolled Square Bar:

(Section of HR Square Bar)

-Length of a side and Theoretical weight of Square Bar.

Length of a side(mm) | Theoretical weight(kg/m) | Length of a side(mm) | Theoretical weight(kg/m) |

6 | 0.283 | 32 | 8.04 |

7 | 0.385 | *33 | 8.55 |

8 | 0.502 | 34 | 9.07 |

9 | 0.636 | *35 | 9.62 |

10 | 0.785 | 36 | 10.17 |

11 | 0.950 | 38 | 11.24 |

12 | 1.13 | 40 | 12.56 |

13 | 1.33 | 42 | 13.85 |

14 | 1.54 | 45 | 15.90 |

15 | 1.77 | 48 | 18.09 |

16 | 2.01 | 50 | 19.63 |

17 | 2.27 | 53 | 22.05 |

18 | 2.54 | *55 | 23.6 |

19 | 2.82 | 56 | 24.61 |

20 | 3.14 | *58 | 26.4 |

21 | 3.46 | 60 | 28.26 |

22 | 3.80 | 63 | 31.16 |

*23 | 4.15 | *65 | 33.17 |

24 | 4.52 | *68 | 36.3 |

25 | 4.91 | 79 | 38.49 |

26 | 5.30 | 75 | 44.16 |

*27 | 5.72 | 80 | 50.24 |

28 | 6.15 | 85 | 56.72 |

*29 | 6.60 | 90 | 63.59 |

30 | 7.06 | 95 | 70.85 |

*31 | 7.54 | 100 | 78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, Formula for theoretical weight of Square bar: a(length of a side) * a * 0.00785

3, The numbers with *mean that they are not regular or we don’t offer them.

-Regular length of Square Bar:

Steel | Length of a side (mm) | Length of steel (m) |

Normal steel | < 25 | 4~10 |

> 25 | 3~9 | |

Steel of high quality | All measure | 2~6 |

Tool steel >75 | 1~6 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: Can steel channels be used for mezzanine flooring?

- Indeed, mezzanine flooring can make use of steel channels. Owing to their robustness, longevity, and capacity to bear weight, steel channels frequently find application in the construction of mezzanine floors. They serve as a dependable foundation for raised platforms and can bear substantial loads. Furthermore, steel channels can be effortlessly integrated with other substances like steel decking or plywood to establish a firm and reliable flooring. In general, steel channels are highly favored for mezzanine flooring due to their structural soundness and capability to endure heavy foot traffic and machinery.

- Q: The pressure is: 50TLength: 1 meters or soMaterial: steel or steelSpecifications: please tell me how much you can use!Prawns help you ah! Urgent! Online, etc.!

- Am I a prawn? Then you use channel 5

- Q: Does anyone know how to calculate the volume of channel steel?!

- Experimental method can be used: if the volume is small and convenient, the "channel" will be integrated into the tank filled with water measurement. Get ready A: a pool full of water. B: an estimate of the amount of water that will be discharged when a channel is placed in a tank full of water. C: put the "channel" into the water tank and load the water discharged by the container. D: the volume of water discharged from the metering unit. That is equal to the volume of the channel. Other liquids that do not destroy channel steel can also be used

- Q: Cautions for surface zinc spraying on channel steel

- Thermal spraying zinc sacrificial anode protection is a single layer of zinc, the corrosion rate depends only on the zinc layer thickness and dissolution rate and inorganic zinc in addition to the protection of zinc layer, the complex chemical changes generated by lithium silicate, zinc silicate, carbonate can better cover metal surface. Secondly, the high porosity of thermal sprayed zinc (3% ~ 5%), another blocking agent brushing waterborne inorganic zinc rich coating with low porosity (usually below 1%), which can be used for thermal spraying zinc surface sealants. In addition, the process of thermal spraying zinc complex, need for high temperature and high pressure and inorganic zinc spraying, brushing is can be flexible operation, the overall comparison, but low cost inorganic zinc.

- Q: Can steel channels be customized to specific lengths?

- Yes, steel channels can be customized to specific lengths.

- Q: How do steel channels compare to other structural steel shapes?

- Steel channels are a versatile structural steel shape that offer several advantages compared to other shapes. They are lightweight yet strong, making them suitable for a wide range of applications. Steel channels provide excellent structural support due to their C-shaped design, which allows for greater load-bearing capacity. Additionally, their flanges can be easily attached to other components, enhancing their versatility in construction projects. Overall, steel channels offer a cost-effective and efficient solution for various structural needs.

- Q: What is the difference between the main keel and the angle steel and the channel steel?

- Channel steel is a strip of steel with a cross section. Section steel with groove shape.Channel steel is a kind of carbon structural steel used for construction and machinery. It is a complex section steel. Its cross section has a groove shape. Channel steel is mainly used in building structure, curtain wall engineering, mechanical equipment and vehicle manufacturing, etc.. In use, it requires better welding, riveting performance and comprehensive mechanical properties. The raw material steel billet for channel steel is carbon or low alloy steel billets with a carbon content of not more than 0.25%. The finished channel steel is delivered by hot forming, normalizing or hot rolling. The specifications are expressed in millimeters of height (H) * leg width (b) * waist thickness (d), such as 100*48*5.3, which means waist height is 100 mm, leg width is 48 mm, waist thickness is 5.3 mm channel, or 10# channel steel. The same height of the channel, if there are several different leg width and waist thickness, also need to add a, B, C on the right side of the model to distinguish, such as 25#a, 25#b, 25#c and so on.

- Q: How are steel channels protected against rusting and corrosion?

- Steel channels are protected against rusting and corrosion through various methods such as coating them with corrosion-resistant materials like zinc or paint, galvanizing them by applying a layer of zinc through a hot-dip process, or using stainless steel channels which have inherent resistance to rusting and corrosion.

- Q: What kind of channel is the best, there is an answer, if not, can come to a formula is OK?

- Section modulus Wx and Wy of channel steel are the same as those of hot-rolled steel (including angle steel and I-beam). They only need to be checked on the ready form.

- Q: What are the different grades of steel channels?

- There are several different grades of steel channels, each with its own unique properties and applications. Some of the commonly used grades include: 1. A36: This is the most common grade of steel channel and is widely used in construction and structural applications. It has a minimum yield strength of 36,000 psi and is easily machinable and weldable. 2. A572: This is a high-strength, low-alloy (HSLA) steel channel grade that offers improved strength and durability compared to A36. It is often used in bridges, buildings, and other heavy-duty applications. 3. A588: This grade of steel channel is known for its corrosion resistance and is primarily used in outdoor or exposed environments. It is commonly used in construction projects where the channel will be subjected to harsh weather conditions. 4. A709: This is another HSLA steel channel grade that offers high strength and improved corrosion resistance. It is commonly used in bridge construction and other structural applications. 5. A992: This is a high-strength, low-alloy steel channel grade that is commonly used in construction and structural applications. It has a higher yield strength and tensile strength compared to A36, making it suitable for heavy-duty applications. 6. Stainless Steel: In addition to carbon steel channels, there are also stainless steel channels available in various grades such as 304 and 316. These grades offer excellent corrosion resistance and are commonly used in industries such as food processing, pharmaceuticals, and marine applications. It is important to select the appropriate grade of steel channel based on the specific requirements of the project, taking into consideration factors such as strength, corrosion resistance, and environmental conditions. Consulting with a structural engineer or steel supplier can help determine the most suitable grade for a particular application.

Send your message to us

Hot Rolled MS Mild Square Steel Bars for Strcutures

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords