Mild stainless steel flat bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering mild stainless steel flat bar for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Mild stainless steel flat bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel flat bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

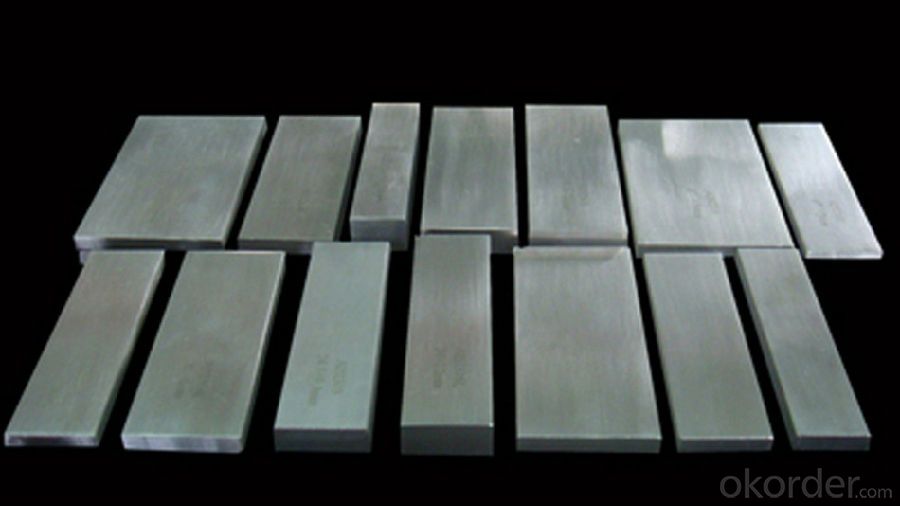

Product Specifications:

Commodity: High Quality Mild Steel Flat Bar

Standard: GB

Material: Q235

Brand name: FLATSPACE

Origin place: China

Thickness: 3mm-30mm

Width:20mm-200mm

Length: Max 12m

Certification: SGS/BV

Chemical composition of Q235

Alloy No | Grade | Element(%) | ||||

C

| Mn

| S

| P

| Si

| ||

Q235

|

B

|

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

Physical properties of Q235

Alloy No | Grade | Yielding strength point(Mpa) | Tensile strength (Mpa) | Elongation after fracture(%) | ||||||

Thickness (mm) | Thickness (mm) | |||||||||

≤16 | >16--40 | >40--60 | >60--100 | ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | ≥ | |||||||||

Q235 |

B |

235 |

225 |

215 |

205 |

375--500 |

26 |

25 |

24 |

23 |

Usage/Applications of High Quality Mild Steel Flat Bar

Widely used for construction, Machinery manufacturing, Iron tower steel structure, Shipbuilding; Steel grating, Staircase, Bridge, Viaduct, Railway spare parts, Boilers making etc.

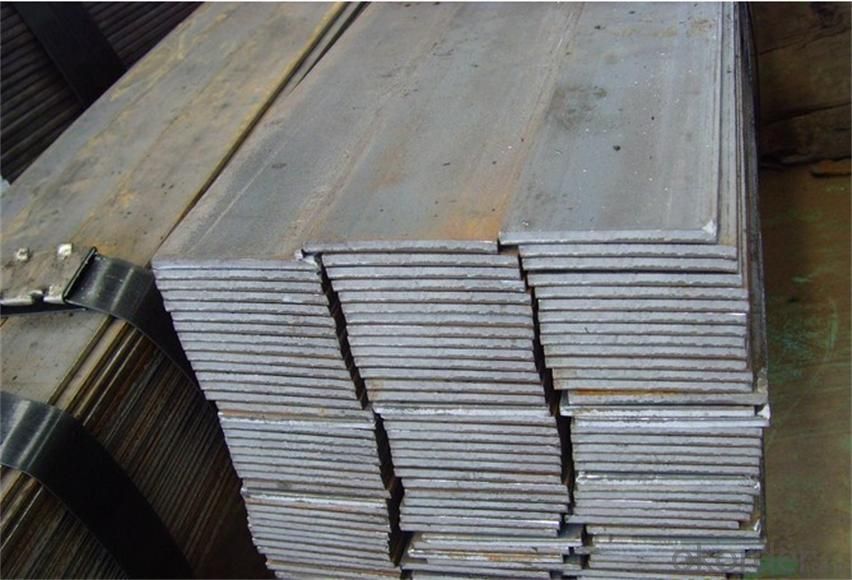

Production Flow of High Quality Mild Steel Flat Bar

The steel flat bar is made through three processes:

1.Feeding the material: Feeding the row material (the steel plate) to Slitting Line.

2.Slitting:The steel plate would be slitted into expected width by lengthways cutter.

3. Leveled and cutting: The plat bar would be ground into level by the grinder and then cut into required length.

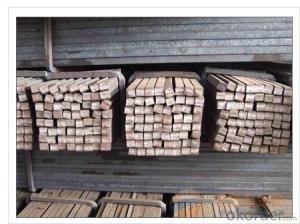

Packaging & Delivery of High Quality Mild Steel Flat Bar

Packaging Details: The Steel Flat Bars are packed in bundles and loaded in 20 feet/40 feet container, or shipped by bulk cargo ,also we can do as customer's requirements.

Delivery Details:30~45 days upon the receipt of buyer payment by T.T. or L/C.

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: Can steel flat bars be used for making molds or dies?

- Certainly, molds or dies can be created using steel flat bars. Steel is a highly versatile material renowned for its robustness and endurance, making it well-suited for a wide range of uses in sectors like manufacturing and engineering. When employed for mold or die fabrication, steel flat bars provide the essential stability and rigidity necessary to endure the pressures and forces involved in the molding or die-cutting procedure. Furthermore, the flat surface of these bars guarantees precise and accurate shaping, thereby enabling the production of top-notch molds or dies. Steel flat bars can be machined, welded, and subjected to heat treatment to attain the desired specifications and characteristics essential for specific molding or die-cutting applications.

- Q: What is the typical width-to-thickness ratio for steel flat bars?

- The width-to-thickness ratio for steel flat bars can differ based on the specific application and requirements. However, a widely utilized ratio is approximately 12:1, implying that the flat bar's width is around 12 times its thickness. This ratio achieves a harmonious equilibrium between structural stability and fabrication convenience, enabling the flat bar to withstand bending and twisting forces while preserving its form and integrity. It is essential to acknowledge that the actual ratio may vary depending on industry norms, engineering specifications, and the intended purpose of the steel flat bar.

- Q: How do steel flat bars compare to wood for certain applications?

- Steel flat bars have several advantages over wood for certain applications. Firstly, steel flat bars are much stronger and more durable than wood, making them ideal for heavy-duty applications that require a high level of strength and stability. Additionally, steel flat bars are not susceptible to rot, decay, or insect damage like wood, making them a more long-lasting option. Moreover, steel flat bars are fire-resistant, making them safer in environments where fire hazards are a concern. Finally, steel flat bars can be easily shaped and manipulated, allowing for greater design flexibility compared to wood. Overall, steel flat bars offer superior strength, durability, and safety benefits, making them a preferred choice for many applications.

- Q: Can steel flat bars be used for making cutting tools?

- Yes, steel flat bars can be used for making cutting tools. Steel is a common material choice for cutting tools as it offers high strength, durability, and sharpness. Steel flat bars can be shaped, sharpened, and hardened to create a variety of cutting tools such as knives, chisels, or shears.

- Q: Can steel flat bars be painted?

- Yes, steel flat bars can be painted. Before painting, it is important to properly prepare the surface by cleaning it thoroughly to remove any dirt, grease, or rust. If there is rust present, it should be removed using sandpaper or a wire brush. Once the surface is clean and smooth, a suitable primer should be applied to ensure good adhesion of the paint. After the primer has dried, a coat or multiple coats of paint can be applied using a paintbrush, roller, or spray paint. It is recommended to use a paint specifically designed for metal surfaces to ensure durability and longevity of the paint job.

- Q: Can steel flat bars be used as support beams?

- Yes, steel flat bars can be used as support beams as they have high strength and load-bearing capacity. However, it is important to consider the specific requirements and structural calculations to ensure they are suitable for the intended purpose and meet the necessary safety standards.

- Q: Are steel flat bars suitable for making toolboxes?

- Indeed, toolboxes can be constructed using steel flat bars. Steel, being a material that is both durable and strong, is well-suited for this purpose, as it allows the toolboxes to endure heavy loads while effectively safeguarding the tools. By conveniently welding steel flat bars together, a robust and dependable structure for the toolbox can be effortlessly formed. Furthermore, the corrosion resistance of steel proves advantageous, particularly for toolboxes that may encounter moisture or harsh surroundings. In summary, the utilization of steel flat bars is a dependable and pragmatic option when crafting toolboxes.

- Q: What are the different international standards for steel flat bars?

- Steel flat bars are subject to various international standards that guarantee their quality and specifications. Some commonly followed standards are as follows: 1. ASTM International (American Society for Testing and Materials): A widely used standard is ASTM A36/A36M, which specifies the requirements for steel flat bars made from carbon structural steel. It covers dimensions, tolerances, chemical composition, mechanical properties, and other relevant aspects. 2. European Norm (EN): The EN 10058 standard is applicable to hot-rolled flat steel bars with a width of 15 mm and above, and a thickness of 1 mm and above. It specifies the tolerances, dimensions, and technical delivery conditions for these bars. 3. Japanese Industrial Standards (JIS): In Japan, the JIS G3194 standard is employed for hot-rolled flat steel bars. It covers the classification, dimensions, and tolerances of these bars, as well as the permissible variations in chemical composition and mechanical properties. 4. British Standards (BS): The BS EN 10025-2 standard delineates the technical delivery conditions for non-alloy structural steels, including flat bars. It encompasses dimensions, tolerances, chemical composition, and mechanical properties, thereby ensuring the quality and performance of these bars. 5. International Organization for Standardization (ISO): ISO 1035-3 provides guidelines for hot-rolled steel bars, including flat bars, manufactured from unalloyed or low-alloy steels. It encompasses the dimensions, tolerances, and technical delivery conditions for these bars. These examples represent a fraction of the international standards that oversee the production, quality control, and specifications of steel flat bars. By adhering to these standards, manufacturers ensure that their products demonstrate consistency, reliability, and compatibility in global markets.

- Q: The difference between use and performance of hot rolled flat steel and longitudinally cut flat steel is discussed

- Hot rolled flat steel (hot rolled flat steel strip):Mostly produced by small factories, the raw material sources are disordered and the material can not be guaranteed. Therefore, the mechanical properties of hot-rolled flat steel are greatly different. Hardness, tensile strength, elongation, weldability are often unpredictable.

- Q: What is the maximum length-to-thickness ratio for a steel flat bar?

- The maximum length-to-thickness ratio for a steel flat bar is typically determined by industry standards and engineering specifications. In general, the maximum recommended length-to-thickness ratio for a steel flat bar is around 160:1. This means that the length of the bar can be up to 160 times its thickness. However, it is important to note that this maximum ratio may vary depending on the specific application and intended use of the steel flat bar. Different industries and engineering disciplines may have their own guidelines and recommendations for maximum length-to-thickness ratios based on factors such as load-bearing capacity, structural stability, and safety considerations. It is always advisable to consult relevant codes, standards, and engineering guidelines specific to the application in order to determine the appropriate maximum length-to-thickness ratio for a steel flat bar. Professional engineers and experts in the field can provide valuable insights and calculations to ensure the structural integrity and safety of the steel flat bar in a given application.

Send your message to us

Mild stainless steel flat bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords