Hot rolled square steel; square steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

There are two types of Square Bar, one is hot rolled square bar and other one is cold drawn square bar. Our principal products is hot rolled square bar. We dedicate to products with material Q195 and Q235. We offer products with high quality and low price.

Specifications of Hot-rolled Square Steel Bar:

-Standard: GB,

-Grade: Q195/Q235 or equivalent.

-Chemical Composition:

Standard | Grade | Element (%) | ||||

C | Mn | S | P | Si | ||

GB | Q195 | 0.06~0.12 | 0.25~0.50 | ≤0.050 | ≤0.045 | ≤0.30 |

GB | Q235B | 0.12~0.20 | 0.30~0.70 | ≤0.045 | ≤0.045 | ≤0.30 |

-Mechanical Properties:

Mechanical Properties | Grade | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | Q195 | ≥195 | ≥185 | - | - |

Q235 | 235 | 225 | 215 | 205 | |

Tensile Strength | Q195 | 315~390 | |||

Q235 | 375~500 | ||||

Elongation δ5% | Q195 | ≥33 | ≥32 | - | - |

Q235 | 26 | 25 | 24 | 23 | |

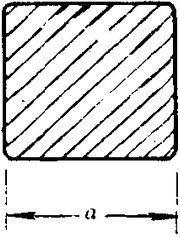

Measures of Hot-rolled Square Steel Bar (Big measures):

(Section of Hot-rolled Square Steel Bar)

-Length of a side and Theoretical weight of Square Bar (Big measures).

Length of a side(mm) | Theoretical weight(kg/m) | Length of a side(mm) | Theoretical weight(kg/m) |

53 | 22.05 | 80 | 50.24 |

56 | 24.61 | 85 | 56.72 |

60 | 28.26 | 90 | 63.59 |

63 | 31.16 | 95 | 70.85 |

70 | 38.49 | 100 | 78.50 |

75 | 44.16 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, Formula for theoretical weight of Square bar: a(length of a side) * a * 0.00785

3, The numbers with *mean that they are not regular or we don’t offer them.

-Regular length of Square Bar:

Steel | Length of a side (mm) | Length of steel (m) |

Normal steel | < 25 | 4~10 |

> 25 | 3~9 | |

Steel of high quality | All measure | 2~6 |

Tool steel >75 | 1~6 |

Usage/Applications of Hot-rolled Square Steel Bar:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

-Row material for steel pipes.

Packaging & Delivery of Hot-rolled Square Steel Bar:

-Packing Detail:

1, The products can be packed in bundles by steel wires.

2, The weight of each bundle no exceed normally 3 tons.

-Marks: We make tag marks and color marks for each bundle. The tag marks with white background and red company log will be tied up to each bundle. The information is usually including basic information of company and products like product name, specification, etc...and other information required by customers. As for color marks, we will paint both ends of each bundles to make sure that it will be more convenient for customers to distinguish theme from other products.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

-The payment terms will be written in contraction detailedly.

- Q: How do you determine the center of a circle using a steel square?

- To determine the center of a circle using a steel square, you can follow these steps: 1. Place the steel square on a flat surface or workbench, ensuring it is level and stable. 2. Take the circle that you want to find the center of and place it on the steel square. Make sure the circle is larger than the steel square so that it extends beyond the edges of the square. 3. Adjust the circle so that it is centered and aligned with the edges of the steel square. You can use a ruler or measuring tape to ensure that the distance from the edge of the circle to the edge of the square is the same on all sides. 4. Once the circle is centered and aligned, draw lines along the edges of the steel square, extending beyond the circle. 5. Using a ruler or straightedge, draw a diagonal line connecting two opposite corners of the square. This diagonal line should pass through the circle's center. 6. Repeat step 5 to draw another diagonal line connecting the other two opposite corners of the square. The intersection point of these two diagonal lines is the center of the circle. 7. Mark the center point clearly on the circle using a pencil or marker. By following these steps and utilizing the right angles and straight edges of the steel square, you can accurately determine the center of a circle.

- Q: How do you use a steel square for framing walls?

- Before using a steel square for framing walls, it is important to verify that the square is clean and devoid of any debris. Afterward, position the square on the lumber's edge, ensuring that one leg is flush against the edge while the other leg is perpendicular to it. To create a straight line, securely hold the square against the lumber's edge and employ a pencil or marker to trace along the leg of the square. This will provide a precise guideline for making accurate cuts or marking measurements. When it comes to making angled cuts, such as for roof rafters or stair stringers, the steel square can be utilized to determine the angle. Place the square on the lumber in a manner that aligns the desired angle with the square's edge, and then mark the line accordingly. Moreover, the steel square can be employed to determine squareness and verify right angles. By positioning the square in the corner where two walls intersect, you can ensure that the corner is perfectly square. If the square fits tightly and the legs align with the walls, then the corner is indeed square. Otherwise, adjustments will need to be made accordingly. In conclusion, the steel square is an essential and versatile tool for framing walls. It enables precise measurements, facilitates straight cuts and angled cuts, and ensures the accuracy of corners.

- Q: What are some common uses for a steel square in stair construction?

- Some common uses for a steel square in stair construction include measuring and marking accurate angles for cutting stringers, determining levelness and plumbness of stairs, and ensuring proper alignment of treads and risers.

- Q: How do you use a steel square to measure board lengths at different angles?

- To use a steel square to measure board lengths at different angles, you would start by placing the square's long side (blade) against the edge of the board. Next, rotate the square until the desired angle aligns with the edge of the board. Once aligned, mark the board along the shorter side (tongue) of the square. Finally, measure the distance from the marked point to the end of the board to determine the length at the specific angle.

- Q: Can a steel square be used for checking the squareness of a jointer knife?

- No, a steel square cannot be used for checking the squareness of a jointer knife. While a steel square is commonly used to check the squareness of woodworking tools and machinery, it is not suitable for this specific task. Jointer knives require a specialized tool called a jointer knife gauge or a magnetic jointer knife setting gauge, which is designed specifically for accurately measuring the squareness of the knife. These gauges typically have a magnet that attaches to the knife, allowing for precise and reliable measurements. Using a steel square for this purpose may lead to inaccurate readings and potentially compromise the performance of the jointer.

- Q: What are some common uses for a steel square in roofing?

- A steel square, also known as a framing square or carpenter's square, is a versatile tool commonly used in roofing projects. Some common uses for a steel square in roofing include: 1. Measuring and marking angles: Steel squares have markings that allow roofers to accurately measure and mark angles for various roof components, such as rafters, trusses, and hips. 2. Laying out roof rafters: A steel square helps roofers lay out and mark the angles and lengths of rafters, ensuring they are cut to the correct dimensions for a precise fit. 3. Determining roof pitch: Roof pitch refers to the steepness or slope of a roof. By using a steel square, roofers can easily determine the roof pitch, which is essential for proper installation and drainage. 4. Checking for squareness: Roofers use a steel square to check if the corners of a roof are square, ensuring the roof structure is properly aligned and balanced. 5. Cutting and shaping roof materials: Steel squares can be used to make accurate cuts on roof materials such as shingles, tiles, and metal sheets. Roofers can align the square along the material's edge to guide their cuts, resulting in precise and clean edges. 6. Creating roof layout patterns: Roofers often use steel squares to create layout patterns for complex roof designs or custom features. By using the square's angles and measurements, they can transfer the desired layout onto the roof surface. 7. Aligning roof trusses and joists: Steel squares are valuable for aligning roof trusses and joists during installation. Roofers can use the square to ensure these components are properly aligned and secure, maintaining the structural integrity of the roof. Overall, a steel square is an essential tool for roofers as it provides accuracy, precision, and versatility in various roofing tasks, making it an indispensable tool in the roofing industry.

- Q: Can a steel square be used for measuring the depth of holes?

- Indeed, the depth of holes can be measured with a steel square. By positioning the elongated, straight side of the steel square parallel to the hole's opening, and aligning the perpendicular side with the hole's vertical surface, one can accurately assess the hole's depth. Simply by attentively noting the intersection point between the perpendicular side and the hole's top, the depth can be deduced by examining the markings etched on the steel square.

- Q: Can a steel square be used for tile border layout?

- Yes, a steel square can be used for tile border layout. A steel square is a versatile tool that is commonly used in woodworking and construction projects. It has measurements marked on its surface and is used to ensure accurate angles and straight lines. When it comes to tile border layout, a steel square can be used to mark and measure the tile edges, ensuring precise and straight cuts for the border tiles. By using a steel square, you can achieve a professional and neat tile border layout.

- Q: How do you use a steel square to mark a line perpendicular to a board edge at a specific distance?

- To use a steel square to mark a line perpendicular to a board edge at a specific distance, follow these steps: 1. Place the steel square against the edge of the board, aligning one arm of the square with the edge. 2. Adjust the square until the other arm is perpendicular to the edge, forming a 90-degree angle. 3. Once the square is properly aligned, hold it firmly against the board to secure its position. 4. Determine the specific distance from the edge where you want to mark the line. For example, if you want the line to be 6 inches away from the edge, measure 6 inches from the edge using a tape measure or ruler. 5. Using a pencil or marking tool, make a mark on the board along the arm of the square that corresponds to the specific distance you measured. 6. Continue marking along the entire length of the board, ensuring that each mark is perpendicular to the edge and at the same specific distance. 7. Once all the marks are made, connect them to form a straight line using a ruler or straight edge. By following these steps, you can utilize a steel square to accurately mark a line perpendicular to a board edge at a specific distance.

- Q: Can a steel square be used for measuring and marking compound bevel and miter cuts?

- Indeed, compound bevel and miter cuts can be measured and marked using a steel square. A steel square, also known as a framing square or carpenter's square, is a versatile tool commonly utilized in woodworking and construction. It possesses a 90-degree angle and a 45-degree angle, rendering it suitable for marking and measuring both bevel and miter cuts. To execute compound bevel cuts, which require the combination of two angles, a steel square can be employed to measure and mark the initial angle. By aligning the square's 45-degree angle with the desired bevel angle, one can utilize the square's edge to establish an accurate reference line for cutting. Similarly, for miter cuts, where two materials must be joined at an angle, a steel square can be employed to measure and mark the necessary angle. By aligning the square's 45-degree angle with the desired miter angle, precise markings for cutting can be created using the square's edge. Nevertheless, it is important to acknowledge that although a steel square can be used for measuring and marking compound bevel and miter cuts, it may not offer the same level of precision and accuracy as specialized tools like a bevel gauge or a miter saw. These specialized tools are explicitly designed for these types of cuts and provide enhanced precision and ease of use. Consequently, while a steel square can serve as a beneficial tool for basic measurements and markings, it is advisable to employ dedicated tools for more intricate compound bevel and miter cuts.

Send your message to us

Hot rolled square steel; square steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords