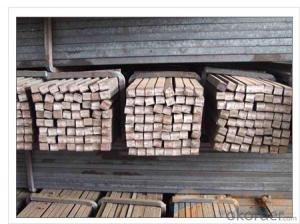

Hot Rolled Steel Square Bar with the Size 180mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Steel Square Bar can be used as steel billet for other steel products like steel angles, channels, I-beams, H-beams, steel Rebar, steel wire rod etc.

Feature:

We have two kinds of Hot Rolled Steel Square Bar which is used as billet, one is produced by blast furnace, the other is produced by electrical arc furnace. The prices are different.

Detail Sizes:

180*180mm

Material Grade:Q235 Q275 3SP 5SP

FAQ:

Packing Detail: The products can be packed naked,loose

The products can be delivered by bulk vessel or by container

Color mark: there will be color marking on both ends of the bundles for the cargo delivered by bulk vessel. That makes is easily to distinguish at the destination port.

Tag mark: the tag marks will be tied up to each bundle. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications and other information requested by customers.

- Q: How do you use a steel square to determine the angle of a compound miter cut?

- In order to determine the angle of a compound miter cut using a steel square, there are a few steps that need to be followed. Firstly, position the steel square against the edge of the material that will be cut. Make sure that the long side of the square is perpendicular to the edge of the material. Next, locate the desired angle for the miter cut. This can be specified in the project plans or chosen based on personal preferences. After determining the angle, use a pencil or marker to draw a line on the material along the edge of the steel square. This line will serve as a guide for the miter cut. Now, rotate the steel square so that the long side aligns with the newly marked line. The short side of the square should now be perpendicular to the edge of the material. At this stage, a protractor or angle finder tool can be used to measure the angle between the short side of the square and the material's edge. This measurement will provide the exact angle for the compound miter cut. Alternatively, if a protractor or angle finder tool is not available, the markings on the steel square can be utilized to estimate the angle. Most steel squares have degree markings along the short side, allowing for direct angle measurement. Once the angle has been determined, a miter saw or other suitable cutting tool can be used to make the compound miter cut according to the measurements. Always remember to wear proper safety gear and adhere to correct cutting techniques when employing power tools.

- Q: Can a steel square be used for deck-building projects?

- Deck-building projects can utilize a steel square, which is also referred to as a framing square or rafter square. This tool, commonly used in construction, is made of heavy-duty steel and is equipped with various measurements and angles. The steel square serves multiple functions in accurate deck construction. It allows for the measurement and marking of straight lines, angles, and cuts. By using the steel square, the deck's initial design can be laid out precisely, ensuring precise dimensions and square corners. This tool is especially beneficial for framing and joist layout, as well as for determining stair height and pitch. Furthermore, the steel square acts as a guide for making straight cuts with a circular saw or handsaw. It guarantees that the cuts are both straight and square, resulting in a professional appearance for the deck. Additionally, it assists in marking and drilling holes for screws or nails, ensuring proper alignment. To summarize, the steel square is an essential tool for deck-building projects. Its durability, versatility, and accuracy make it invaluable to both DIY enthusiasts and professional contractors.

- Q: Can a steel square be used for tile backsplash layout?

- Yes, a steel square can be used for tile backsplash layout. A steel square is a versatile tool that can help with accurate measurements and angles, ensuring precise tile placement. It can be used to create straight lines, right angles, and check for levelness during the layout process.

- Q: What are some common applications for a steel square in plumbing installations?

- Some common applications for a steel square in plumbing installations include measuring and marking angles for cutting pipes, checking for squareness and straightness of pipes and fittings, and ensuring proper alignment and spacing of fixtures and components.

- Q: How do you use a steel square to determine the center of a circle?

- To use a steel square to determine the center of a circle, place the square on the circle so that the edges of the square intersect the circle at two points. Then, draw a line connecting these two points on the circle. Repeat this process with another pair of intersecting points on the circle. The point where these two lines intersect is the center of the circle.

- Q: How do you use a steel square to measure and mark 90-degree angles?

- To use a steel square to measure and mark 90-degree angles, place one arm of the square against the edge of the material you want to measure. Ensure that the other arm is perpendicular to the first arm and aligns with the edge of the material. Once aligned, use a pencil or a scribe to mark the 90-degree angle at the intersection of the two arms of the square.

- Q: How do you use a steel square to measure and mark out rip cuts?

- To use a steel square to measure and mark out rip cuts, follow these steps: 1. Place the square's long edge against the board's edge, ensuring it is flush and aligned. 2. Slide the square along the board until the desired rip width is aligned with the opposite edge. 3. Use a pencil to mark the board at the square's short edge, indicating the starting point of the rip cut. 4. Repeat the process along the length of the board, marking multiple points if necessary. 5. Connect the marked points with a straight line using a straightedge or by freehand if confident. 6. Double-check the measurements and lines before making any cuts to ensure accuracy.

- Q: What are the common accessories that come with a steel square?

- The common accessories that come with a steel square typically include a protective case or sheath, an instruction manual or guide booklet, and sometimes a carpenter's pencil or marking tool.

- Q: How do you use a steel square for making accurate miter cuts?

- To use a steel square for making accurate miter cuts, follow these steps: 1. Start by ensuring that your steel square is clean and free from any dirt or debris. This will help in achieving accurate measurements. 2. Place the steel square flat against the edge of the material you wish to make the miter cut on. Ensure that the square is aligned properly and that the angle you want to cut is perpendicular to the square. 3. Hold the square firmly against the material, making sure it doesn't move or shift. It's a good idea to use clamps or a vise to secure the square in place if necessary. 4. Use a pencil or a marking knife to mark the line where you want to make the miter cut. Make sure to align the square with the desired angle and trace along the edge of the square to create an accurate line. 5. Double-check the alignment of the square before proceeding. It's crucial to ensure that the square hasn't moved during the marking process. 6. Now, using a miter saw or a handsaw, carefully follow the marked line to make the miter cut. Take your time and make precise cuts to achieve the desired angle. 7. After making the cut, check the accuracy of the miter by placing the two cut pieces together. They should fit snugly and form a perfect angle. If adjustments are needed, use sandpaper or a file to fine-tune the cut until the desired fit is achieved. Remember, practice and patience are key when using a steel square for making accurate miter cuts. With time, you will become more proficient and achieve precise and clean cuts for your woodworking projects.

- Q: What are some common uses for a steel square in metal fabrication?

- A steel square, also known as a framing square or a carpenter's square, is a versatile tool that is commonly used in metal fabrication for a variety of purposes. Some of the common uses for a steel square in metal fabrication include: 1. Measuring and marking: A steel square is an essential tool for accurately measuring and marking metal pieces. It is particularly useful in ensuring precise angles and lines, which are crucial in metal fabrication. 2. Squaring corners: Metal fabrication often requires precise right angles and squared corners. A steel square is used to ensure that corners are perfectly square, allowing for accurate and seamless welding or joining of metal pieces. 3. Checking for flatness: Metal sheets or plates should ideally be flat and level before fabrication. A steel square can be used to check for any warping or bending in the metal surface, helping to identify and correct any imperfections before further processing. 4. Layout work: The tool's straight edges and angles are useful in layout work, which involves marking and positioning various components before assembly. Steel squares help in accurately transferring measurements and creating templates for cutting or shaping metal pieces. 5. Drafting and designing: Steel squares are often used in drafting and designing metal structures or components. They aid in creating precise drawings, making accurate calculations, and ensuring that the final product meets the required specifications. 6. Angle measurements: Steel squares are equipped with a protractor scale that allows for measuring and marking various angles. This feature is beneficial in metal fabrication, where specific angles are required for cutting, bending, or welding metal pieces. 7. Setting up machinery: Steel squares are also useful during the setup of machinery in metal fabrication workshops. They can be used to align and position machines, ensuring that they are level and accurately placed for optimal performance. Overall, a steel square is an indispensable tool in metal fabrication, providing accuracy, precision, and versatility in various tasks such as measuring, marking, squaring corners, checking flatness, layout work, drafting, designing, angle measurements, and machinery setup.

Send your message to us

Hot Rolled Steel Square Bar with the Size 180mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches