Hot Rolled Steel Square Bar Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

| 1.Specification | ||||||||

| Square bar | Diameter(mm) | Length (mm) | ||||||

| 20~600 | 3000~9000 | |||||||

| Plate | Thickness(mm) | Width (mm) | Length (mm) | |||||

| Max:800 | Max:2200 | Max:9000 | ||||||

| *Specification can be customized for sure. | ||||||||

| 2.Chemical Compositons | ||||||||

| Grade | C | Si | Mn | P | S | Cr | Mo | Ni |

| SCM440 | 0.38~0.45 | 0.17~0.37 | 0.50~0.8 | ≤0.035 | ≤0.035 | 0.9~1.2 | 0.15-0.25 | ≤0.3 |

| 4140 | 0.40~0.45 | 0.15~0.35 | 0.75~1.0 | ≤0.035 | ≤0.040 | 0.8~1.1 | 0.15-0.25 | - |

| SCM415 | 0.38~0.43 | 0.15~0.35 | 0.60~0.9 | ≤0.030 | ≤0.030 | 0.9~1.2 | 0.15-0.30 | ≤0.25 |

| 1.7225 | 0.38~0.45 | ≤0.40 | 0.60~0.9 | ≤0.025 | ≤0.035 | 0.9~1.2 | 0.15-0.30 | |

| 3.Delivery Conditions | ||||||||

| Hot rolled +Rough machined (black surface after Q/T)+ Turned (optional) | ||||||||

| 4.Typical Applications | ||||||||

| a.Statically and dynamically stressed components for vehicles | ||||||||

| b.Parts of larger cross-sections, crankshafts, gears | ||||||||

| c.Gears, stem assemblies, | ||||||||

| d.Pump shafts and tool holders | ||||||||

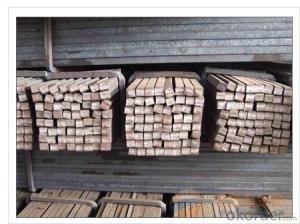

Product Image:

FAQ

Q: Can I get sample and how long will it take?

A:Yes. We can supply sample. And you need to pay for courier.

Q: What's the MOQ?

A: Our MOQ is 1000mt.

Q: What's the delivery time?

A: It will take about 30-45 days after TT or L/C.

Q: What is the payment terms?

A: T/T, L/C at sight

Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

Q: What certificate do you have?

A: We have SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.

- Q: How are steel products used in the railway industry?

- Steel products are extensively used in the railway industry for various applications. Steel is commonly used for manufacturing railway tracks, train wheels, and various structural components of the railway infrastructure. Additionally, steel is used in the construction of railway cars, locomotives, and various equipment such as bridges, tunnels, and signaling systems. Its high strength, durability, and ability to withstand heavy loads make steel an ideal material for ensuring the safety and efficiency of the railway system.

- Q: How does the thickness of steel affect its strength?

- The thickness of steel directly affects its strength, as thicker steel tends to have greater strength. This is because the thickness of the steel provides resistance to external forces and reduces deformation under stress. Thicker steel can withstand higher loads and is less prone to bending or breaking, making it more durable and stronger in various applications.

- Q: How is steel used in the production of elevator systems?

- Steel is used extensively in the production of elevator systems due to its strength, durability, and reliability. It is used for constructing the elevator shaft, frame, and car, providing structural support and ensuring the safety of passengers. Steel is also used for manufacturing various components such as guide rails, doors, and counterweights, contributing to the smooth operation and efficient functioning of the elevator system.

- Q: How is steel used in the construction of warehouses and storage facilities?

- Steel is commonly used in the construction of warehouses and storage facilities due to its strength and durability. It is used for the framework and support structures, as well as for roofing and siding. Steel provides a secure and reliable structure that can withstand heavy loads and harsh weather conditions, making it ideal for these types of buildings.

- Q: What are the different types of steel chains and their applications?

- There are several types of steel chains, each designed for specific applications. Some common types include: 1. Proof coil chains: These are general-purpose chains used for towing, securing loads, and restraining objects in various industries. 2. Grade 30 chains: Also known as Grade 30 proof coil chains, these are commonly used in light-duty applications, such as agriculture, construction, and general-purpose lifting. 3. Grade 43 chains: These chains have higher tensile strength than Grade 30 chains and are suitable for heavier-duty applications, including transportation, logging, and towing. 4. Grade 70 chains: Known as transport chains, these chains are specifically designed for securing cargo on trucks, trailers, and flatbeds. They have a higher strength-to-weight ratio, making them ideal for load binding. 5. Grade 80 chains: These chains are mostly used in lifting applications due to their high strength and durability. They are commonly found in construction, mining, and oil and gas industries. 6. Grade 100 chains: These chains have the highest tensile strength and are primarily used for heavy-duty lifting and rigging applications. They are commonly seen in shipyards, steel mills, and offshore operations. 7. Stainless steel chains: These chains are resistant to corrosion and are suitable for applications where exposure to moisture or chemicals is a concern. They are commonly used in food processing, marine environments, and medical equipment. Overall, the choice of steel chain depends on the specific application requirements, load capacity, environment, and desired level of durability.

- Q: How is steel used in the construction of industrial buildings and warehouses?

- Steel is commonly used in the construction of industrial buildings and warehouses due to its strength and durability. It is used to create structural components such as beams, columns, and frames, providing a sturdy framework that can support heavy loads and withstand harsh conditions. Additionally, steel is often used for roofing and cladding materials, offering protection against weather elements and ensuring long-term durability. Its versatility allows for efficient construction and customization, making it a popular choice in industrial building and warehouse projects.

- Q: What are the different types of steel wires and their applications in the automotive industry?

- There are several types of steel wires commonly used in the automotive industry, including high carbon steel wire, stainless steel wire, and alloy steel wire. High carbon steel wire is known for its strength and durability, making it suitable for applications such as tire reinforcement, suspension springs, and seat frames. Stainless steel wire, on the other hand, offers corrosion resistance and is often used in exhaust systems, fuel lines, and brake cables. Lastly, alloy steel wire combines different elements to enhance specific properties, such as tensile strength or heat resistance, and finds applications in components like engine valves and transmission gears.

- Q: How are steel profiles used in the construction of underground tunnels?

- Steel profiles are commonly used in the construction of underground tunnels to provide structural support and stability. These profiles are often used to create the framework or skeleton of the tunnel, ensuring that it can withstand the pressure from the surrounding soil or rock. The steel profiles are designed and installed in a way that allows them to bear the load and distribute it evenly, preventing collapse or deformation of the tunnel. Additionally, steel profiles can be used to reinforce tunnel walls, ceilings, and floors, adding further strength and durability to the structure.

- Q: How are steel products used in the construction of schools and educational institutions?

- Steel products are widely used in the construction of schools and educational institutions for various purposes. They are commonly used in the structural framework, such as columns, beams, and trusses, to provide support and stability to the buildings. Additionally, steel is used in the construction of roofs, walls, and floors due to its durability and ability to withstand heavy loads. Steel products also play a crucial role in the construction of doors, windows, and other architectural features, ensuring safety and security. Overall, steel products are essential in creating sturdy and long-lasting educational facilities.

- Q: How is steel used in the production of machinery and equipment?

- Steel is widely used in the production of machinery and equipment due to its strength, durability, and versatility. It is used to manufacture various components such as frames, casings, gears, and bearings, providing the necessary structural integrity and mechanical capabilities. Steel's ability to withstand high temperatures, corrosion, and heavy loads makes it ideal for applications in heavy machinery, construction equipment, automotive industry, and many other sectors.

Send your message to us

Hot Rolled Steel Square Bar Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords