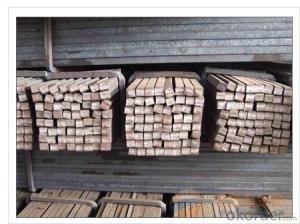

Mild Hot Rolled Steel Square Bars for Structure

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Mild Hot Rolled Steel Square Bars for Structure at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

-The Mild Hot Rolled Steel Square Bars for Structure is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Product Advantages:

OKorder's Mild Hot Rolled Steel Square Bars for Structure are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Description:

Length of a side(a, mm) | Theoretical weight(kg/m) | Length of a side(a, mm) | Theoretical weight(kg/m) |

6 | 0.283 | 32 | 8.04 |

7 | 0.385 | *33 | 8.55 |

8 | 0.502 | 34 | 9.07 |

9 | 0.636 | *35 | 9.62 |

10 | 0.785 | 36 | 10.17 |

11 | 0.950 | 38 | 11.24 |

12 | 1.13 | 40 | 12.56 |

13 | 1.33 | 42 | 13.85 |

14 | 1.54 | 45 | 15.90 |

15 | 1.77 | 48 | 18.09 |

16 | 2.01 | 50 | 19.63 |

17 | 2.27 | 53 | 22.05 |

18 | 2.54 | *55 | 23.6 |

19 | 2.82 | 56 | 24.61 |

20 | 3.14 | *58 | 26.4 |

21 | 3.46 | 60 | 28.26 |

22 | 3.80 | 63 | 31.16 |

*23 | 4.15 | *65 | 33.17 |

24 | 4.52 | *68 | 36.3 |

25 | 4.91 | 79 | 38.49 |

26 | 5.30 | 75 | 44.16 |

*27 | 5.72 | 80 | 50.24 |

28 | 6.15 | 85 | 56.72 |

*29 | 6.60 | 90 | 63.59 |

30 | 7.06 | 95 | 70.85 |

*31 | 7.54 | 100 | 78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with *mean that they are not regulars or we don’t offer them.

-The allowed tolerance of Square Steel:

Length of a side(mm) | Allowed Tolerance | ||

Group1 | Group2 | Group3 | |

5.5~7 | ±0.20 | ±0.30 | ±0.40 |

7~20 | ±0.25 | ±0.35 | ±0.40 |

20~30 | ±0.30 | ±0.40 | ±0.50 |

30~50 | ±0.40 | ±0.50 | ±0.60 |

60~80 | ±0.60 | ±0.70 | ±0.80 |

80~110 | ±0.90 | ±1.0 | ±1.1 |

110~150 | ±1.2 | ±1.3 | ±1.1 |

150~190 | ―― | ―― | ±2.0 |

190~250 | ―― | ―― | ±2.5 |

Packaging & Delivery of Mild Hot Rolled Steel Square Bars for Structure:

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks:

1, Tag marks: the tag marks will be tied up to each bundle of the products. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications, the painted color and other information requested by customers.

2, Color marks: we will paint both ends of the bundles of these products to make sure that they are more evident. It’s will be more convenient for the customers to distinguish them at the destination port.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation:

-The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: Can fit in the containers of 20fts the steel beams of 6M?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q: Are steel round bars suitable for high-pressure applications?

- Steel round bars are frequently a good choice for high-pressure applications. Steel is renowned for its strength and durability, making it an ideal material for handling high pressure. Round bars, in particular, possess exceptional tensile strength and resistance to deformation, rendering them suitable for utilization in high-pressure settings like hydraulic systems, oil and gas pipelines, and structural applications. Furthermore, steel round bars can be customized to meet specific strength and hardness criteria, further enhancing their aptness for high-pressure applications. Nevertheless, it is crucial to carefully consider the requirements of the particular application and seek advice from an engineer or industry expert to guarantee the selection of the most appropriate grade and size of steel round bar for optimal performance and safety.

- Q: What are the different methods of cutting steel round bars?

- There are several methods of cutting steel round bars, including sawing, shearing, torch cutting, and using a lathe or milling machine.

- Q: What are the advantages of using high-temperature steel round bars?

- Using high-temperature steel round bars in various applications has several advantages. Firstly, these bars possess excellent heat resistance properties, enabling them to withstand elevated temperatures without compromising their structural integrity. This makes them ideal for industries like aerospace, automotive, and power generation, where components are exposed to extreme heat conditions. Another advantage of high-temperature steel round bars is their superior strength and durability. They are designed to withstand high mechanical stresses, making them suitable for applications requiring heavy loads or intense pressure. Additionally, their high strength-to-weight ratio allows for lighter and more efficient designs, reducing overall material and production costs. Furthermore, high-temperature steel round bars exhibit excellent corrosion resistance properties. They can withstand exposure to harsh environments, including chemicals, moisture, and saltwater, without significant degradation. This makes them suitable for industries like marine, chemical, and oil and gas where corrosion resistance is crucial. Moreover, high-temperature steel round bars offer excellent dimensional stability, maintaining their shape and size even under extreme temperature fluctuations. This property is highly advantageous in applications where precision and accuracy are essential, such as machining and tooling. Lastly, high-temperature steel round bars are readily available in various sizes, grades, and finishes, allowing for flexibility and customization to meet specific project requirements. This versatility makes them suitable for a wide range of applications, ensuring that there is a suitable option for every project, regardless of complexity or industry. In conclusion, high-temperature steel round bars provide superior heat resistance, strength, durability, corrosion resistance, dimensional stability, and versatility. These properties make them an excellent choice for various industries and applications, guaranteeing reliable and long-lasting performance in demanding environments.

- Q: Can steel round bars be used in the manufacturing of bearings?

- Yes, steel round bars can be used in the manufacturing of bearings. Steel is a common material used for bearing manufacturing due to its high strength, durability, and ability to withstand heavy loads and friction. The steel round bars are typically machined and processed to form the bearing components, such as the inner and outer rings, rollers, or balls, which are then assembled to create the final bearing product.

- Q: Are steel round bars resistant to chemicals?

- Yes, steel round bars are generally resistant to a wide range of chemicals. However, the level of resistance may vary depending on the specific type of steel and the particular chemical being used.

- Q: What are the advantages of using chromium-molybdenum alloy steel round bars?

- There are several advantages of using chromium-molybdenum alloy steel round bars: 1. High Strength: Chromium-molybdenum alloy steel round bars have excellent strength properties, making them suitable for applications that require a high level of strength and durability. This makes them ideal for use in heavy machinery, construction equipment, and other demanding applications. 2. Corrosion Resistance: The addition of chromium in the alloy steel composition enhances its corrosion resistance properties. This makes chromium-molybdenum alloy steel round bars highly resistant to rust and other forms of corrosion, making them suitable for use in harsh environments and outdoor applications. 3. Heat Resistance: Chromium-molybdenum alloy steel round bars have excellent heat resistance properties, allowing them to withstand high temperatures without losing their structural integrity. This makes them suitable for use in applications that involve high temperature conditions, such as in boilers, pressure vessels, and heat exchangers. 4. Wear Resistance: The presence of molybdenum in the alloy steel composition provides excellent wear resistance properties. This means that chromium-molybdenum alloy steel round bars can withstand the effects of wear and abrasion, making them suitable for use in applications that involve high levels of friction and wear, such as in mining equipment, drilling tools, and automotive components. 5. Machinability: Chromium-molybdenum alloy steel round bars have good machinability, allowing them to be easily shaped and formed into various configurations. This makes them suitable for use in applications that require complex shapes and designs, such as in automotive parts, machine components, and tooling. Overall, the advantages of using chromium-molybdenum alloy steel round bars make them a popular choice for a wide range of applications in various industries. They offer high strength, corrosion resistance, heat resistance, wear resistance, and good machinability, making them a reliable and versatile material for many demanding applications.

- Q: Can steel round bars be used for making shock absorber components?

- Yes, steel round bars can be used for making shock absorber components. Steel is a common material choice for shock absorber components due to its strength, durability, and ability to withstand high levels of stress and impact. The round shape of the bars also allows for easy machining and fabrication of the necessary components.

- Q: Can steel round bars be used for making tie rods?

- Yes, steel round bars can be used for making tie rods. Steel round bars are commonly used in construction and engineering applications due to their strength and durability. Tie rods are used to provide structural support and stability, and steel round bars are well-suited for this purpose. They have high tensile strength and can withstand heavy loads and tension, making them an ideal choice for tie rods. Additionally, steel round bars can be easily fabricated and welded, allowing for customization and versatility in the design and construction of tie rods.

- Q: What are the maximum allowable stresses for steel round bars?

- The maximum allowable stresses for steel round bars depend on various factors such as the grade of steel, the type of loading, and the design code being followed. In general, the maximum allowable stress for steel round bars is determined by the yield strength of the steel. The yield strength is the stress at which permanent deformation or yielding of the material occurs. Different grades of steel have different yield strengths. For example, mild steel typically has a yield strength of around 250 MPa (megapascals), while high-strength low-alloy (HSLA) steel can have a yield strength of up to 550 MPa. To determine the maximum allowable stress, typically a safety factor is applied to the yield strength. This safety factor takes into account uncertainties in material properties, loadings, and potential variations in manufacturing processes. The safety factor can vary depending on the application and design code being followed. For example, in structural steel design, the American Institute of Steel Construction (AISC) specifies a safety factor of 1.67 for the yield strength. This means that the maximum allowable stress would be the yield strength divided by 1.67. It is important to consult relevant design codes, standards, or engineering specifications for specific applications to determine the appropriate maximum allowable stresses for steel round bars.

- Q: Can steel round bars be used for making fasteners?

- Certainly! Fasteners can indeed be made using steel round bars. Manufacturers commonly utilize steel round bars to produce fasteners like bolts, screws, and rivets. The strength and durability of steel make it an excellent choice for fasteners, as it can endure significant stress and ensure a secure connection. Moreover, steel round bars can be conveniently machined and threaded to achieve the desired shape and size required for fasteners. In summary, steel round bars are highly dependable and frequently employed in the manufacturing process of fasteners.

Send your message to us

Mild Hot Rolled Steel Square Bars for Structure

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords