Mild steel billet for hot rolled steel products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15950 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

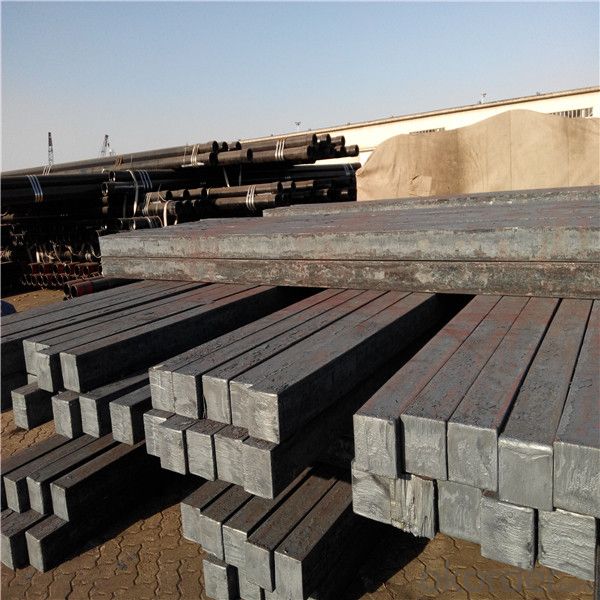

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed

into more functional shapes and sizes. While they have already been put in the furnace, they still require

a series of shaping and molding procedures such as hot and cold working, milling and cutting before they

are sold in hardware stores, or used for different applications. The unformed billets, however, can be used

in striking currency such as coins and as reserves, similar to gold bars.

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What are the different types of steel billet surface treatments?

- There are several different types of steel billet surface treatments, including pickling, shot blasting, and painting. Pickling involves removing impurities and oxides from the surface of the billet using an acid solution. Shot blasting is a process in which small metallic or abrasive particles are blasted onto the surface of the billet to remove rust, scale, and other contaminants. Painting involves applying a protective coating or layer of paint to the surface of the billet to prevent corrosion and improve its appearance.

- Q: How are steel billets used in the manufacturing of packaging materials?

- Steel billets are used in the manufacturing of packaging materials by being rolled into thin sheets to create metal containers or cans. These billets are first heated and then passed through a series of rolling machines to achieve the desired thickness. These sheets are further processed and shaped to form different types of packaging materials such as cans, boxes, or containers, which provide durability and strength to protect and preserve various products during transportation and storage.

- Q: What are the different surface defects found in tool steel billets?

- There are several different surface defects that can be found in tool steel billets. These defects can occur during the manufacturing process or can be the result of handling, transportation, or storage. Some of the common surface defects found in tool steel billets include: 1. Decarburization: This defect occurs when the surface of the steel billet loses its carbon content due to exposure to high temperatures during heat treatment or improper cooling. Decarburization can lead to reduced hardness and wear resistance in the tool steel. 2. Scale: Scale refers to the formation of oxide layers on the surface of the steel billet. It can occur during the hot rolling process or due to exposure to high temperatures. Scale can negatively impact the surface finish and can also affect the mechanical properties of the tool steel. 3. Cracks: Cracks can occur on the surface of tool steel billets due to various reasons such as improper cooling, excessive stress during hot rolling, or quenching. These cracks can be either surface cracks (which are visible) or internal cracks (which may not be immediately visible). 4. Inclusions: Inclusions are non-metallic particles or impurities that are trapped within the steel billet during the manufacturing process. These inclusions can cause weak spots or discontinuities in the material, leading to reduced toughness and fatigue resistance. 5. Pitting: Pitting refers to the formation of small holes or cavities on the surface of the steel billet. It can be caused by localized corrosion, exposure to aggressive environments, or improper handling. 6. Roll marks: Roll marks are surface imperfections that occur due to the contact between the steel billet and the rolls during the hot rolling process. These marks can appear as grooves, scratches, or indentations on the surface of the tool steel. 7. Surface contamination: Tool steel billets can get contaminated with foreign substances such as dirt, oil, grease, or other particles during handling, transportation, or storage. These contaminants can negatively affect the surface finish and can also lead to corrosion or other defects. It is important to detect and address these surface defects in tool steel billets to ensure the desired performance and reliability of the final tooling products. Various inspection techniques and quality control measures are employed to identify and mitigate these defects, such as visual inspection, ultrasonic testing, magnetic particle inspection, and surface cleaning processes.

- Q: How do steel billets contribute to the manufacturing of HVAC systems?

- The role of steel billets in the manufacturing of HVAC systems is crucial. These systems rely on strong and durable components to ensure efficient operation and longevity, and steel billets serve as the foundation for such components. To begin with, steel billets are utilized to construct the primary structural framework of HVAC systems. This framework, also known as the casing or housing, offers support and protection for the internal components including heat exchangers, fans, and coils. Steel billets possess high strength and rigidity, making them an ideal choice for creating a sturdy and dependable framework that can withstand the various stresses and strains encountered during system operation. Furthermore, steel billets are employed in the production of various internal components of HVAC systems. For instance, steel billets are commonly used to manufacture heat exchangers, which play a crucial role in transferring heat between the air and the refrigerant. Steel's high thermal conductivity and corrosion resistance make it an excellent material for these critical components, ensuring efficient heat transfer and long-term performance. Moreover, steel billets are utilized in the manufacturing of ductwork. Ductwork consists of a network of pipes or channels that distribute conditioned air throughout a building. Steel billets are often rolled and formed into the necessary shapes to create the ducts. The strength and durability of steel guarantee that the ductwork can withstand the pressure differentials and mechanical stresses associated with air movement, thereby maintaining the integrity of the system and preventing leaks. Additionally, steel billets are essential for the production of HVAC system supports and brackets. These components are responsible for securely mounting various equipment, such as air handling units or condensing units. Steel's strength and load-bearing capacity make it an ideal material for ensuring the stability and proper installation of these crucial elements. In conclusion, steel billets are vital in the manufacturing of HVAC systems as they provide the necessary strength, durability, and thermal properties for the structural framework, internal components, ductwork, and supports. Without steel billets, it would be extremely challenging to produce HVAC systems that deliver efficient heating, ventilation, and air conditioning to buildings.

- Q: How are steel billets used in the production of reinforcement bars?

- Steel billets are a crucial component in the production of reinforcement bars, also known as rebar. These billets, which are essentially semi-finished steel products in a rectangular or square shape, serve as the starting point for the manufacturing process. To produce reinforcement bars, steel billets are first heated in a furnace to a temperature above their recrystallization point. This process is known as hot rolling. The heated billets are then passed through a series of rollers, which gradually reduce their cross-sectional area and elongate the material. As a result, the billets are transformed into long, slender bars with the desired dimensions and mechanical properties. During the hot rolling process, the steel billets undergo significant plastic deformation. This deformation causes the grains within the material to realign and form a more uniform and compact structure. This refined microstructure enhances the strength and durability of the reinforcement bars, making them suitable for use in construction projects where high tensile strength is required, such as in reinforced concrete structures. The size and shape of the steel billets used in the production of reinforcement bars vary depending on the specific requirements of the end product. It is important to note that the quality of the billets is a critical factor in determining the quality of the final rebar. Therefore, manufacturers must carefully select and inspect the billets to ensure they meet the necessary specifications and standards. In summary, steel billets are essential in the production of reinforcement bars as they are transformed through the hot rolling process into the desired shape and dimensions. The resulting rebar possesses improved strength and durability, making it suitable for reinforcing concrete structures and ensuring their structural integrity.

- Q: What are the potential applications of steel billets in the chemical industry?

- Due to their unique properties and versatility, steel billets have numerous potential applications in the chemical industry. One primary use of steel billets in the chemical industry involves their utilization in the production of various types of equipment and machinery. Steel billets can be shaped and forged into different forms, such as pipes, tanks, valves, and fittings, which are crucial for the handling and storage of chemicals. These components need to withstand harsh conditions, including high temperatures, pressures, and corrosive environments, thereby making steel billets an ideal material choice. Additionally, steel billets can be employed in the construction of chemical plants and facilities. They provide exceptional structural support, ensuring the stability and integrity of the buildings. Steel billets are often used in fabricating beams, columns, and other load-bearing elements, providing strength and durability to withstand the chemical processes occurring within the plant. Another potential application of steel billets in the chemical industry pertains to the manufacturing of reaction vessels and reactors. These vessels are utilized for chemical reactions, such as synthesis, distillation, and purification processes. Steel billets can be machined and formed into the desired shape, allowing for the creation of robust and reliable vessels that can handle the high pressures and temperatures often required in chemical reactions. Furthermore, steel billets can be utilized in the production of catalysts used in various chemical processes. Catalysts are substances that expedite chemical reactions without being consumed in the process. Steel billets can serve as a base material for catalysts, providing a stable and durable support structure for the active catalytic components. Moreover, steel billets can be employed in the construction of storage tanks and containers for the transportation and storage of chemicals. Steel billets offer exceptional resistance to corrosion and can be easily welded and fabricated into large containers, ensuring the safe and secure storage of hazardous chemicals. In summary, steel billets possess vast potential applications in the chemical industry. Their strength, durability, and resistance to corrosion make them indispensable materials for various chemical processes and operations, encompassing equipment fabrication, construction projects, catalyst manufacturing, and storage solutions.

- Q: What is the role of steel billets in the manufacturing of machinery?

- Steel billets play a crucial role in the manufacturing of machinery due to their versatile nature and desirable properties. These semi-finished steel products are essentially long, rectangular bars that serve as the raw material for producing various machinery components. Firstly, steel billets are known for their strength, durability, and excellent mechanical properties, making them ideal for the construction of heavy-duty machinery. By using high-quality billets, manufacturers can ensure that the resulting machinery will have the strength and structural integrity necessary to withstand the demanding operating conditions and loads. Secondly, steel billets can be easily molded and shaped into different forms and sizes through various manufacturing processes like forging, rolling, or extrusion. This versatility allows machinery manufacturers to create complex components with intricate designs, ensuring precision and functionality. Furthermore, the uniformity and consistency of steel billets contribute to the reliability and performance of machinery. As billets undergo a controlled cooling process during their production, they acquire a uniform microstructure, minimizing the risk of defects and improving the overall quality of the machinery components manufactured from them. Another important aspect is the machinability of steel billets, which refers to their ability to be easily cut, drilled, or shaped using machine tools. This property allows manufacturers to efficiently produce machinery components with precise dimensions and tolerances, saving time and costs in the manufacturing process. Moreover, steel billets can be heat-treated to enhance their mechanical properties, such as hardness, toughness, and resistance to wear or corrosion. This makes them suitable for critical machinery parts that require specific characteristics to ensure optimal performance and longevity. In summary, steel billets are indispensable in the manufacturing of machinery due to their strength, versatility, uniformity, and machinability. They provide the necessary raw material for producing robust and reliable machinery components that can withstand demanding conditions and meet the performance requirements of various industries.

- Q: How are steel billets rolled into rails?

- Steel billets are rolled into rails through a process called hot rolling. In this process, the steel billets are heated to high temperatures and then passed through a series of rolling mills. As the billets are rolled, they are gradually shaped into the desired rail profile. This process ensures that the steel retains its strength and durability, making it suitable for use as railway tracks.

- Q: Billet market trend

- 1, domestic crude steel production remains highAlthough the recent domestic steel market has been relatively low, and the loss of steel mills win less, but this does not seem to affect the enthusiasm of steel production. According to the China Steel Association statistics show that: in early April, the daily output of crude steel in key enterprises in China was 1 million 697 thousand and 300 tons, and the average daily output of crude steel in China was estimated at 2 million 123 thousand and 900 tons. And in mid April, crude steel daily output of ten days, although there has been a drop back, but still at a high level. According to statistics, in mid April, the average daily output of crude steel in key enterprises nationwide was 1 million 689 thousand and 100 tons, and the average daily output of crude steel in China was estimated at 2 million 115 thousand and 800 tons. Such a large production and sluggish demand in stark contrast, which is a drag on steel prices down one of the important factors.

- Q: How do steel billets contribute to the overall safety of a structure?

- Steel billets contribute to the overall safety of a structure by providing a strong and durable material for construction. The high strength and toughness of steel billets make them resistant to external forces such as earthquakes, wind, and heavy loads. Additionally, steel billets have excellent fire resistance, as they do not burn or release toxic gases when exposed to high temperatures. This ensures the structural integrity of the building during a fire. Moreover, steel billets can be easily fabricated into various shapes and sizes, allowing for precise engineering and construction, which further enhances the safety and stability of the structure.

Send your message to us

Mild steel billet for hot rolled steel products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 15950 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords