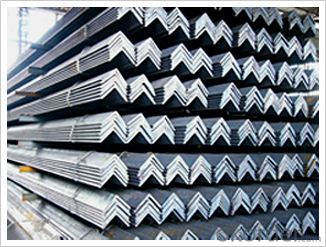

Hot rolled sheet Equal Steel Angle bar DIN 1028

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1.Grade: SS200,300,400 series

2.Size: 25×25×3 mm-100×100×10mm

3.Process: HRAP

4. Length: 2-6m

5. Shape: Equal

6. Delivery: within 20 days

7. MOQ: 1 ton

8. Certificate: ISO 9001:2008, SGS

9. Package:Standard Export Packing, or put into wooden boxes according to your requirement

10. Application: Construction, Marine, Industry and so on

Name | Stainless Steel Angles | ||||||

Standard | ASTM A554, A312, A249, A269 and A270 | ||||||

Material Grade | 304,316,201,202, 316L,430 | ||||||

Length | 6m or as customers' request | ||||||

Tolerance | a) thickness: +/-0. 15mm | ||||||

b) Length:+/-4. 5mm - 0mm | |||||||

Surface | 180G, 320G, 400G Satin / Hairline(Matt Finish, Brush, Dull Finish) 400G, 500G, 600G or 800G Mirror finish | ||||||

Application | Decoration construction, upholstery, industry instruments | ||||||

Test | Squash test, Extended test, Water pressure test, Crystal rot test, Heat treatment, NDT | ||||||

Chemical Composition of Material |

Composition

Material | 201 | 202 | 304 | 316L | 430 | |

C | ≤0.15 | ≤0.15 | ≤0.08 | ≤0.08 | ≤0.12 | ||

Si | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ≤1.00 | ||

Mn | 5.5-7.5 | 7.5-10 | ≤2.00 | ≤2.00 | ≤1.00 | ||

P | ≤0.06 | ≤0.06 | ≤0.045 | ≤0.045 | ≤0.040 | ||

S | ≤0.03 | ≤0.03 | ≤0.030 | ≤0.030 | ≤0.030 | ||

Cr | 16-18 | 17-19 | 18-20 | 16-18 | 16-18 | ||

Ni | 3.5-5.5 | 4-6 | 8-10.5 | 10-14 | |||

Mo | 2.0-3.0 | ||||||

Mechanical Property | Material Item | 201 | 202 | 304 | 316L | ||

Tensile Strength | ≥535 | ≥520 | ≥520 | ≥520 | |||

Yield Strength | ≥245 | ≥205 | ≥205 | ≥205 | |||

Extension | ≥30% | ≥30% | ≥35% | ≥35% | |||

Hardness (HV) | <253 | <253 | <200 | <200 | |||

FAQ:

Q1: How do we guarantee the quality of our products?

A1: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Images:

- Q: How do steel angles contribute to the sustainability of transportation systems?

- Steel angles contribute to the sustainability of transportation systems by providing structural support and stability to various components such as bridges, railways, and highways. Their high strength-to-weight ratio ensures efficient use of material, reducing the overall environmental impact. Additionally, steel angles are durable and resistant to corrosion, requiring minimal maintenance and extending the lifespan of transportation infrastructure, ultimately promoting sustainability.

- Q: What are the advantages of using steel angles in manufacturing?

- There are several advantages of using steel angles in manufacturing. Firstly, steel angles provide excellent structural support and stability, making them ideal for various applications such as constructing buildings, bridges, and machinery. Secondly, steel angles have high tensile strength and durability, ensuring long-lasting and reliable performance. Additionally, steel angles are versatile and can be easily customized and fabricated to meet specific design requirements. Lastly, steel angles are cost-effective, readily available, and have a high recyclability rate, making them an environmentally-friendly choice for manufacturers.

- Q: Can steel angles be used in telecommunications or broadcasting structures?

- Yes, steel angles can certainly be used in telecommunications or broadcasting structures. Steel angles provide structural support and stability, making them ideal for constructing towers, antennas, and other infrastructure required for telecommunications and broadcasting purposes.

- Q: How do steel angles perform under dynamic loads?

- Steel angles generally perform well under dynamic loads due to their inherent strength and durability. The structural shape of steel angles, characterized by their L-shaped cross-section, provides excellent resistance to bending and torsional forces. This design allows them to efficiently distribute dynamic loads and resist deformation, making them suitable for various applications in construction, engineering, and manufacturing industries. However, the specific performance of steel angles under dynamic loads can vary depending on factors such as the grade and quality of the steel, the magnitude and frequency of the dynamic load, and the overall design and reinforcement of the structure.

- Q: What are the different methods of joining steel angles?

- There are various methods of joining steel angles, including welding, bolting, riveting, and using adhesive bonds. Each method offers its own advantages and considerations depending on the specific application and requirements.

- Q: How do you store steel angles?

- Steel angles can be stored by stacking them horizontally on a flat and stable surface, ensuring that they are separated by wooden blocks or dunnage to prevent any damage or deformation. It is advisable to keep them in a dry and well-ventilated area to prevent rust or corrosion. Additionally, storing them indoors or under a weatherproof covering can provide further protection against environmental elements.

- Q: What are the design considerations for incorporating steel angles into a structure?

- When incorporating steel angles into a structure, several design considerations need to be taken into account. First and foremost, the load-bearing capacity of the steel angles must be carefully assessed to ensure they can support the intended loads. The dimensions and thickness of the angles should be determined based on the structural requirements and anticipated stress levels. Additionally, the connection details between the steel angles and other structural elements need to be carefully designed to ensure they provide sufficient strength and rigidity. Considerations should include the type of fasteners, welding techniques, and any additional reinforcement required to achieve the desired structural integrity. Furthermore, factors such as corrosion protection, fire resistance, and durability should also be considered during the design process. Appropriate measures should be taken to prevent rust and corrosion on the steel angles, such as applying protective coatings or using stainless steel. Fire-resistant coatings or fireproofing materials may also be necessary, depending on the building's fire safety requirements. Lastly, aesthetics and architectural considerations may come into play when incorporating steel angles into a structure. The design should take into account the desired visual appearance, whether the angles will be exposed or concealed, and how they will integrate with the overall architectural style. In conclusion, the design considerations for incorporating steel angles into a structure involve assessing load-bearing capacity, connection details, corrosion protection, fire resistance, durability, and aesthetic integration.

- Q: What is the bending capacity of a steel angle?

- The bending capacity of a steel angle refers to its ability to withstand bending or flexing without breaking or deforming excessively. It is a measure of the angle's structural strength and is typically determined by factors such as the dimensions and thickness of the angle, the type of steel used, and any additional reinforcements or supports present. The bending capacity is usually expressed in terms of the maximum amount of load or stress that the angle can endure before it reaches its yield point, which is the point at which it permanently deforms. The bending capacity of a steel angle can vary widely depending on these factors, and it is crucial to consider this capacity when designing and constructing structures that utilize steel angles to ensure their structural integrity and safety.

- Q: What is the difference between galvanized steel angle and ordinary angle iron?

- Ordinary angle iron and hot galvanized steel angle per ton difference of about 2500 yuan.

- Q: Can steel angles be used for support frames in industrial machinery?

- Indeed, support frames in industrial machinery can make effective use of steel angles. Construction and fabrication often rely on steel angles for their remarkable traits of strength, durability, and versatility. These angles offer structural stability and support to a wide range of structures, including machinery frames. The availability of steel angles in multiple sizes and thicknesses allows for customization to meet precise load-bearing needs. Moreover, steel's inherent rigidity and exceptional tensile strength render it an optimal choice for supporting heavy machinery and equipment within industrial environments.

Send your message to us

Hot rolled sheet Equal Steel Angle bar DIN 1028

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords