Quick Details

Standard: ASTM, GB, JIS

Grade: SGCH

Thickness: 0.13mm-0.8mm

Place of Origin: Tianjin, China (Mainland)

Brand Name: ZG

Model Number: ZG

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Galvanized

Width: 750mm-1250

Length: 0

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Standard: ASTM, GB, JIS

Grade: SGCH

Thickness: 0.13mm-0.8mm

Place of Origin: Tianjin, China (Mainland)

Brand Name: ZG

Model Number: ZG

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Galvanized

Width: 750mm-1250

Length: 0

| Packaging Details: | seaworthy standard export packing .CARDBOARD SLEEVES, STEEL SHEET WRAPPED OUTSID, FIXED BY STEEL BELT |

|---|---|

| Delivery Detail: | Within 30-40 days upon receit of you prepaid money |

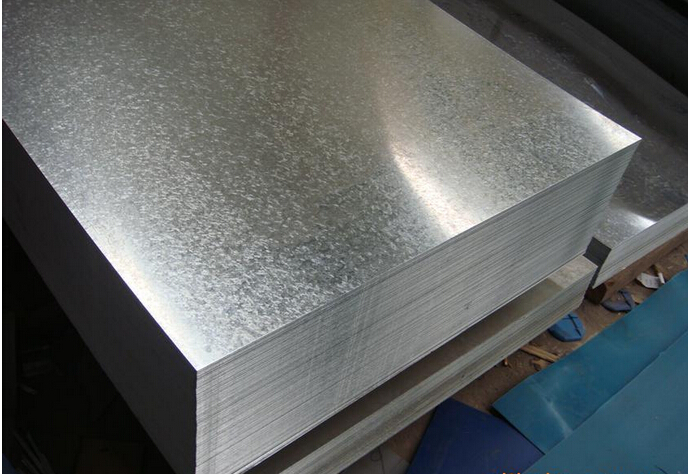

Galvanized steel sheet /coil features:

1. Zinc coating :30-150g/m2( as required)

2. Thickness:0.13-0.8mm

3. Width:750-1250mm(750-762mm,900-925mm, 1000, 1200-1250mm the most common)

4. Coil id:508mm

5. Coil weight: 3-5MT or more (as required)

6. Surface:regular/mini/big spangle, skin pass, chromated, unoiled, dry etc.

7. Tolerance:Thickness tolerance: +/- 0.02mm;

Width tolerance: +/-5mm;

Zinc tolerance:+/-10gsm.

8.Payment condition: Prepay 30%, pay the rest before shipment, via TT

8. Application: As to excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

Send your message to us

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords