Hot Rolled Stainless Steel 316L Grade NO.1 Finish Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

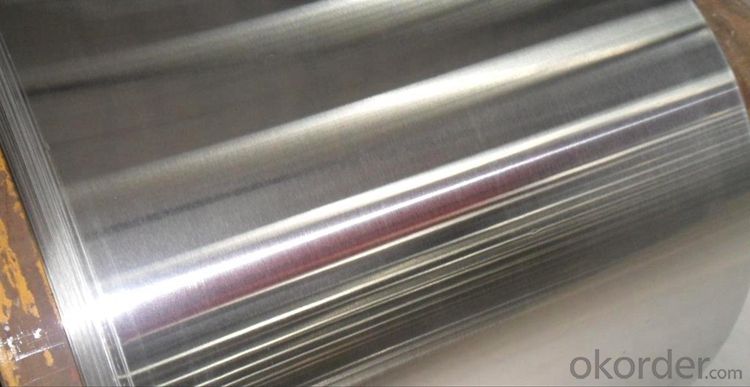

Description for Stainless Steel Coils/Sheets:

Material | 201/202/301/304/304L/310S/316/316L/321/410/420 |

Technique | Cold Rolled, Cold Drawn, Hot Rolled |

Standard | ASTM,AISI,JIS,GB,DIN,EN |

Thickness | 0.3mm-100mm or as your requirement |

Width | 100mm-3000mm or as your requirement |

Length | 1000mm-10000mm or as your requirement |

Surface Treatment | BA,2B,No.1,No.4,No.8,HL,8K,Brush |

Packing | 1.Export sea worthy package + water proof paper + wooden pallet 2. Max Loading 26.5mt for each 20Gp container 3.Safe loading and fixing Professiona teams 4. Professional shipping line |

Delivery | 5 days after received the 30% deposit of T/T or L/C |

Payment | T/T,30%payment in advance,70%T/T after the copy of B/L or L/c at sight |

Application | Stainless Steel Sheets are widely used in below fields: 1: Construction field, shipping building industry 2: Petroleum and Chemical Industries 3: Food and Mechanical Industries |

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Detail picture for Stainless Steel Coils/Sheets

Payment&Delivery for Stainless Steel Coils/Sheets:

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy |

Delivery Time | With 30-40 days after deposit |

Price Terms | Ex-Work, FOB, CNF, CFR, CIF,etc |

- Q: Can stainless steel sheets be used for sink fabrication?

- Certainly, sink fabrication can make use of stainless steel sheets. Undeniably, stainless steel stands as a favored material for sinks owing to its strength, ability to resist corrosion, and appealing appearance. By easily molding and joining stainless steel sheets, a sink design without visible seams can be effortlessly achieved, thanks to their pliability and adaptability to specific measurements and styles. Moreover, stainless steel boasts hygienic properties and simple maintenance, rendering it a sensible option for kitchen and bathroom sinks.

- Q: 304 how can the water stain on the surface of stainless steel plate be formed?

- If you want to scrub the proposal as soon as possible processing, water Jiyue long more difficult to wear off, if it is ferrite, also easy to rust.

- Q: What is the elongation of stainless steel sheets?

- The elongation of stainless steel sheets refers to the ability of the material to stretch or deform without breaking when subjected to tensile forces. It is expressed as a percentage of the original length of the sheet that it can be stretched before fracturing occurs. The elongation of stainless steel sheets can vary depending on the specific grade of stainless steel and its manufacturing process. Generally, stainless steel sheets have a higher elongation compared to other metals, such as carbon steel, due to their higher ductility. However, the exact elongation value can vary depending on factors such as the grade, thickness, and tempering of the stainless steel sheet.

- Q: What are the benefits of using perforated stainless steel sheets in acoustics?

- Perforated stainless steel sheets in acoustics offer several benefits. Firstly, they can effectively control and manipulate sound waves by allowing sound to pass through the perforations while reducing the intensity of the sound energy. This helps in creating a more balanced and controlled acoustic environment. Secondly, these sheets can be used as sound absorbers, as the holes in the stainless steel sheet absorb and dissipate sound energy, reducing echoes and reverberations. Additionally, perforated stainless steel sheets are durable, corrosion-resistant, and aesthetically pleasing, making them a long-lasting and visually appealing solution for acoustic applications.

- Q: Are stainless steel sheets suitable for elevator buttons?

- Indeed, elevator buttons can be made from stainless steel sheets. The reason behind this preference for stainless steel lies in its remarkable durability, resistance to corrosion, and effortless upkeep. Given that elevator buttons are frequently pressed by countless individuals throughout the day, stainless steel can endure the strain and continuous usage without compromising its visual allure. Moreover, stainless steel boasts simple cleaning and sanitizing procedures, rendering it an excellent hygienic option for elevator buttons. In summary, stainless steel sheets represent a superb choice for elevator buttons, delivering both resilience and a stylish, contemporary look.

- Q: What are the bending limits of stainless steel sheets?

- The bending limits of stainless steel sheets are contingent upon several factors, including the stainless steel grade, sheet thickness, and the specific bending process employed. Stainless steel sheets are renowned for their exceptional strength and durability, enabling them to be bent to a certain degree without fracturing or breaking. As a general rule, stainless steel sheets can be bent to a radius that is at least twice the thickness of the sheet. For instance, a 1mm thick sheet can typically be bent to a minimum radius of 2mm. It is crucial to note, however, that this is merely a general guideline, and the actual bending limits may differ based on the particular stainless steel grade. Certain stainless steel grades, such as 304 and 316, possess higher yield strengths and greater resistance to deformation, rendering them suitable for more demanding bending applications. Thicker sheets also exhibit higher bending limits in comparison to thinner ones, as they possess more material to withstand the forces of bending. Moreover, it is important to mention that the chosen bending process can impact the bending limits of stainless steel sheets. Press brake bending and roll bending are commonly employed methods for bending stainless steel sheets. These processes employ distinct techniques and equipment, resulting in varying bending limits. To ascertain the exact bending limits for a specific stainless steel sheet grade and thickness, it is advisable to refer to the manufacturer's specifications or seek guidance from a professional metal fabricator. They possess the expertise and knowledge to provide precise information and guidance on the bending capabilities of stainless steel sheets tailored to your specific application.

- Q: What are the different types of colored finishes available for stainless steel sheets?

- There are several different types of colored finishes available for stainless steel sheets. These finishes are designed to enhance the appearance of stainless steel and provide various aesthetic options. Some of the most common colored finishes include: 1. Mirror Finish: This finish is highly reflective and creates a mirror-like surface on stainless steel sheets. It is achieved by polishing the stainless steel surface to a high gloss. Mirror finishes are commonly used in decorative applications and provide a sleek and modern look. 2. Satin Finish: Also known as brushed or matte finish, this type of finish has a smooth, non-reflective surface. It is achieved by brushing the stainless steel surface with an abrasive material. Satin finishes are commonly used in architectural and industrial applications and provide a clean and contemporary appearance. 3. Colored Powder Coating: Powder coating involves applying a dry powder to the stainless steel surface and then curing it under heat. This process creates a durable and uniform colored finish. Colored powder coatings are available in a wide range of hues, allowing for customization and versatility in design. 4. PVD Coating: Physical Vapor Deposition (PVD) is a process that involves depositing a thin layer of metal onto the stainless steel surface. This coating can be in various colors, such as gold, bronze, black, or rose gold. PVD coatings provide excellent durability and resistance to wear, making them suitable for high-traffic areas or decorative applications. 5. Colored Anodizing: Anodizing is an electrochemical process that creates a protective oxide layer on the stainless steel surface. By using dyes during the anodizing process, a wide range of colors can be achieved. Colored anodized finishes are known for their corrosion resistance and can be utilized in architectural or design-oriented applications. Each of these colored finishes offers unique characteristics and can be chosen based on the desired aesthetic, durability, and specific application requirements. It is important to consider factors such as the level of maintenance needed, environmental conditions, and the intended use of the stainless steel sheets when selecting a colored finish.

- Q: What are the different types of stainless steel sheets available?

- There are several different types of stainless steel sheets available in the market, each with its own unique properties and applications. Some of the most common types include: 1. Austenitic Stainless Steel Sheets: This type of stainless steel is the most widely used and offers excellent corrosion resistance, high strength, and good formability. It is commonly used in kitchen equipment, food processing plants, and pharmaceutical industries. 2. Ferritic Stainless Steel Sheets: Ferritic stainless steel sheets have a higher chromium content and lower carbon content compared to austenitic stainless steel. They are known for their excellent resistance to stress corrosion cracking and are often used in automotive applications, architectural structures, and appliances. 3. Martensitic Stainless Steel Sheets: Martensitic stainless steel sheets have a higher carbon content compared to other types, which gives them high strength and hardness. They are commonly used in applications requiring wear resistance, such as cutlery, surgical instruments, and turbine blades. 4. Duplex Stainless Steel Sheets: Duplex stainless steel sheets have a mixed microstructure of austenite and ferrite, which provides them with a combination of high strength and excellent corrosion resistance. They are often used in chemical processing plants, oil and gas industries, and marine environments. 5. Precipitation Hardening Stainless Steel Sheets: Precipitation hardening stainless steel sheets are heat-treatable and offer high strength and corrosion resistance. They are commonly used in aerospace applications, defense equipment, and high-performance industries. It's important to consider the specific requirements of your project or application when choosing the type of stainless steel sheet, as each type has its own set of properties and advantages.

- Q: Are stainless steel sheets resistant to staining?

- Stainless steel sheets possess a remarkable resistance to staining due to their high chromium content. This abundance of chromium creates a protective layer on the metal's surface, referred to as the passive layer, which effectively prevents the steel from interacting with oxygen and moisture in the surroundings. Consequently, stainless steel becomes immune to rust and corrosion. Moreover, the smooth and non-porous nature of stainless steel surfaces makes it challenging for stains to infiltrate and cling onto the material. Although stainless steel sheets may eventually exhibit some signs of staining, they can be effortlessly cleaned and restored to their original condition with minimal exertion. Consequently, stainless steel sheets are widely favored in various settings, including kitchens, hospitals, and industrial environments, where stain resistance is of utmost importance.

- Q: Are stainless steel sheets resistant to acids?

- Yes, stainless steel sheets are resistant to acids. Stainless steel is known for its corrosion resistance, and this resistance extends to acids as well. The chromium content in stainless steel forms a protective layer, known as a passive film, that prevents the metal from reacting with acids. This passive film acts as a barrier, making stainless steel sheets highly resistant to a wide range of acids, including both organic and inorganic acids. However, it is important to note that the level of resistance can vary depending on the grade and composition of the stainless steel. Some grades, such as 304 and 316, are particularly resistant to acids, making them suitable for various applications in industries such as chemical processing, food processing, and pharmaceuticals. Nonetheless, even with their resistance to acids, stainless steel sheets may still be susceptible to certain aggressive acids or prolonged exposure to highly corrosive environments. Therefore, it is essential to consult with experts and choose the appropriate grade of stainless steel for specific acid-resistant applications.

Send your message to us

Hot Rolled Stainless Steel 316L Grade NO.1 Finish Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords