Packaging & Delivery

| Packaging Details: | suitable for export with hooks for easy unloading of material with bundle weight. |

|---|---|

| Delivery Detail: | two weeks after advance or lc |

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

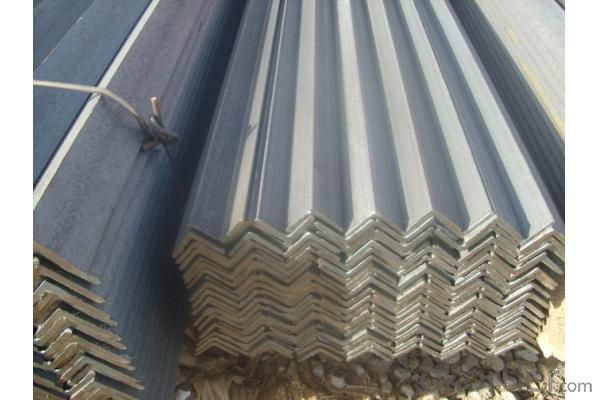

Standard:GB

Dimensions:20x20x2mm--200x200x20mm

Grade:Q235

Model Number:20x20x2mm--200x200x20mm

Type:Equal

Application:constructure

| Packaging Details: | suitable for export with hooks for easy unloading of material with bundle weight. |

|---|---|

| Delivery Detail: | two weeks after advance or lc |

Send your message to us

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords